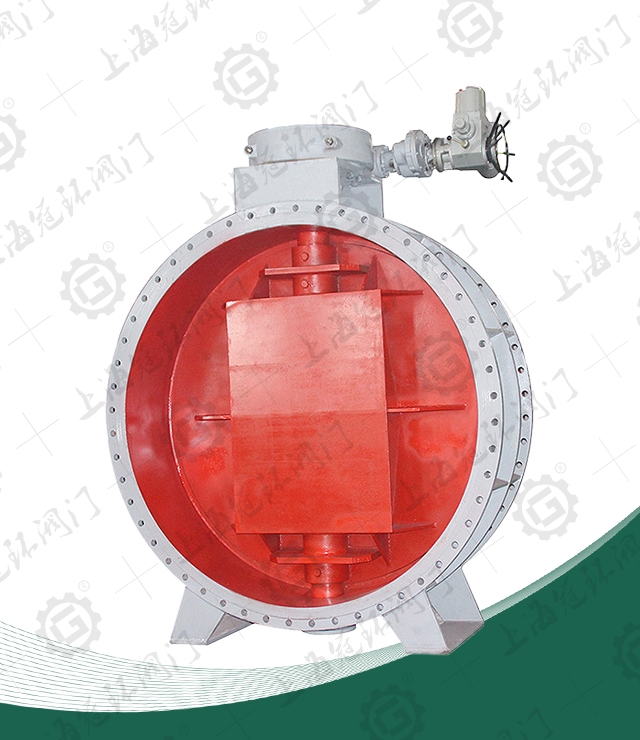

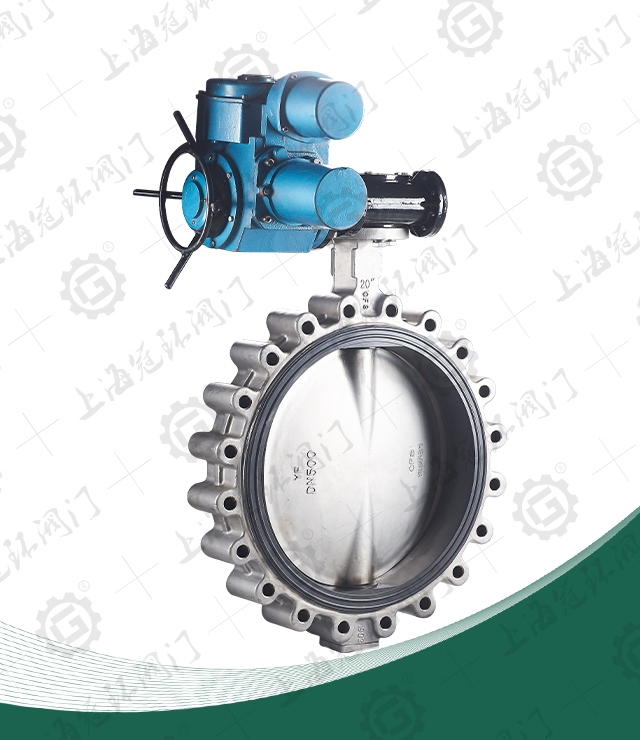

Top entry eccentric hemispherical valve (electric)

Product model: DYQ40 type

Nominal diameter: DN100~1400mm

Nominal pressure: PN1.0~1.6MPa

Main material: carbon steel WCB/stainless steel CF8

Applicable media: natural gas, coal gas, liquefied gas, crude oil, heavy oil

Applicable temperature: ≤ 425 ℃

Flange connection size: GB/T 9113.1-2000. ASME/ANSI 16.5

Structure length: GB 12221-2005, ASNE B16.10

Manufacturing and acceptance: GB12237-89, API 6D

Pressure test according to JB/T9092-1999, GB/T13927-92, AP1598

The upper eccentric hemisphere valve adopts the principle of eccentric structure, and achieves the purpose of locking, adjusting, and closing through the transmission mechanism. The double eccentric structure ball valve is hidden in the valve chamber when opened, with a large flow load surface. When closed, the spherical surface of the valve core gradually moves along the valve seat, with shear function, effectively removing scaling obstacles and achieving reliable sealing. Suitable for wastewater treatment, pulp, alumina, urban heating, oil products, natural gas, liquid solid two-phase mixtures, or media prone to chemical crystallization.

Product Features

1. Tightly sealed, delivering harmful gases with zero leakage.

2. The hemisphere of the valve is made of bimetallic material, with

different alloys overlaid on the base material. The valve seat is also

subjected to corresponding welding and special treatment to meet the

needs of different occasions.

3. The valve core of the sealing pair

has a compensation amount left, and when the valve is worn out, it can

be reliably sealed by turning a little more when closed, extending its

service life.

4. Its structure adopts the eccentric compression

principle to achieve the purpose of locking, adjusting, and closing

through the transmission mechanism.

Main performance specifications

|

nominal pressure |

0.6 |

1.0 |

1.6 |

2.0 |

2.5 |

4.0 |

5.0 |

6.4 |

10 |

|

|

Shell Test Pressure |

0.9 |

1.5 |

2.4 |

3.0 |

3.8 |

6.0 |

7.5 |

9.6 |

15 |

|

|

High pressure sealing test |

0.66 |

1.1 |

1.8 |

2.2 |

2.8 |

4.4 |

5.5 |

7.1 |

11 |

|

|

Applicable medium and temperature℃ |

DYQ40type |

Solutions such as water, steam, pulp, etct≤180℃ |

||||||||

|

DYQ40type |

Natural gas, gas, liquefied gas, crude oil, heavy oil t ≤425℃ |

|||||||||

|

DYQ40type |

Solution, slurry, aluminum oxide powder, coal powder, coal ash, dusty gas, waste residue, etc t ≤300℃ |

|||||||||

Main component materials

|

Part Name |

DYQ40 type |

DYQ40 type |

DYQ40 type |

|

valve body |

Carbon steel WCB/stainless steel CF8 |

Carbon steel WCB/stainless steel CF8 |

Carbon steel WCB/stainless steel CF8 |

|

valve stem |

2Cr13/304 |

2Cr13/304 |

2Cr13/304 |

|

Valve core sealing pair |

WCB/CF8+Cr |

WCB/CF8+Hardened alloy steel |

Special hardened alloy steel |

|

Valve seat sealing pair |

PTFE/Molon |

WCB/CF8+Hardened alloy steel |

Special hardened alloy steel |

|

nominal pressure |

Nominal Diameter |

Size(mm) |

|||||||

|

L |

D |

K |

d |

b |

z-d0 |

Hw |

Hd |

||

|

1.0MPa |

100 |

229 |

220 |

180 |

156 |

22 |

8-φ18 |

330 |

380 |

|

125 |

254 |

210 |

210 |

184 |

22 |

8-φ18 |

345 |

405 |

|

|

150 |

267 |

240 |

240 |

211 |

24 |

8-φ22 |

370 |

440 |

|

|

200 |

292 |

295 |

295 |

266 |

24 |

8-φ22 |

405 |

470 |

|

|

250 |

330 |

350 |

350 |

319 |

26 |

12-φ22 |

480 |

540 |

|

|

300 |

403 |

400 |

400 |

370 |

26 |

12-φ22 |

520 |

580 |

|

|

350 |

430 |

460 |

460 |

429 |

26 |

16-φ22 |

570 |

630 |

|

|

400 |

530 |

515 |

515 |

480 |

26 |

16-φ26 |

630 |

710 |

|

|

450 |

580 |

565 |

565 |

530 |

28 |

20-φ26 |

690 |

770 |

|

|

500 |

660 |

620 |

620 |

582 |

28 |

20-φ26 |

740 |

820 |

|

|

600 |

840 |

725 |

725 |

682 |

34 |

20-φ30 |

840 |

940 |

|

|

700 |

900 |

840 |

840 |

794 |

34 |

24-φ30 |

960 |

1040 |

|

|

800 |

1000 |

950 |

950 |

901 |

36 |

24-φ33 |

1080 |

1180 |

|

|

900 |

1100 |

1050 |

1050 |

1001 |

38 |

28-φ33 |

1190 |

1280 |

|

|

1000 |

1200 |

1160 |

1160 |

1112 |

38 |

28-φ36 |

1310 |

1420 |

|

|

1200 |

1300 |

1380 |

1380 |

1328 |

44 |

32-φ39 |

1420 |

1530 |

|

|

1400 |

1500 |

1590 |

1590 |

1530 |

48 |

36-φ42 |

1540 |

1650 |

|

|

1.6MPa |

100 |

229 |

180 |

180 |

156 |

22 |

8-φ18 |

330 |

380 |

|

125 |

254 |

210 |

210 |

184 |

22 |

8-φ18 |

345 |

405 |

|

|

150 |

267 |

240 |

240 |

211 |

24 |

8-φ22 |

370 |

440 |

|

|

200 |

292 |

295 |

295 |

266 |

24 |

12-φ22 |

405 |

470 |

|

|

250 |

330 |

355 |

355 |

319 |

26 |

12-φ26 |

480 |

540 |

|

|

300 |

403 |

410 |

410 |

370 |

28 |

12-φ26 |

520 |

580 |

|

|

350 |

430 |

470 |

470 |

429 |

30 |

16-φ26 |

570 |

630 |

|

|

400 |

530 |

525 |

525 |

480 |

32 |

16-φ30 |

630 |

710 |

|

|

450 |

580 |

650 |

585 |

548 |

40 |

20-φ30 |

690 |

770 |

|

|

500 |

660 |

770 |

650 |

609 |

44 |

20-φ33 |

740 |

820 |

|

|

600 |

840 |

840 |

770 |

720 |

54 |

20-φ36 |

840 |

940 |

|

|

700 |

900 |

950 |

840 |

794 |

40 |

24-φ36 |

960 |

1040 |

|

|

800 |

1000 |

1050 |

950 |

901 |

42 |

24-φ39 |

1080 |

1180 |

|

|

900 |

1100 |

1125 |

1050 |

1001 |

44 |

28-φ39 |

1190 |

1280 |

|

|

1000 |

1200 |

1255 |

1170 |

1112 |

46 |

28-φ42 |

1310 |

1420 |

|

|

1200 |

1300 |

1485 |

1390 |

1328 |

52 |

32-φ48 |

1420 |

1530 |

|

|

1400 |

1500 |

1590 |

1590 |

1530 |

58 |

36-φ48 |

1540 |

1650 |

|

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333