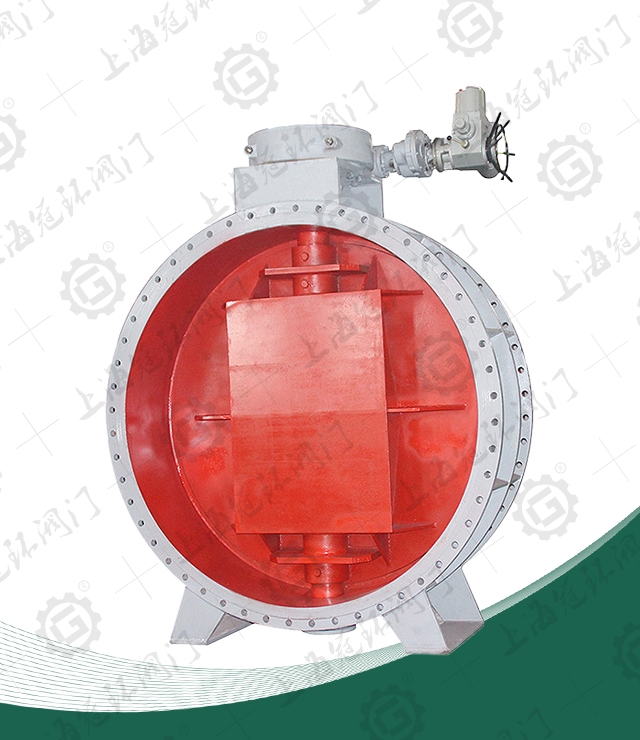

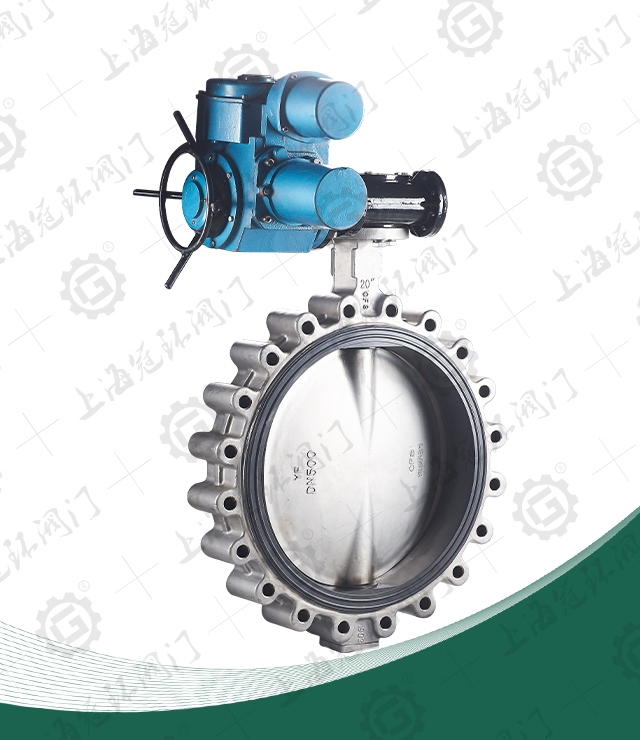

Electric clamp type hard seal butterfly valve

Nominal diameter: DN50~1200mm

Pressure range: PN1.0~2.5MPa

Applicable temperature: carbon steel: -29 ℃~400 ℃, stainless steel: -40 ℃~600 ℃

Applicable media: air, water, sewage, steam, gas, oil, etc

Valve material: cast steel, stainless steel

Manufacturing standard: JB/T8527-1997

Flange standard: GB/T9113-2000

Length standard: GB/T12221-1989

Inspection standard: GB/T13927-1992

Main performance specification

|

DN50~1200 | ||||

|

PN(MPa) | 0.6 | 1.0 | 1.6 | 2.5 |

|

|

0.9 | 1.5 | 2.4 | 3.75 |

|

0.66 | 1.1 | 1.76 | 2.75 | |

| Low pressure airtight test | 0.5~0.7 | ||||

|

Air, water, sewage, steam, gas, oil, etc | ||||

|

carbon steel:-29℃~400℃ 、stainless steel:-40℃~600℃ | ||||

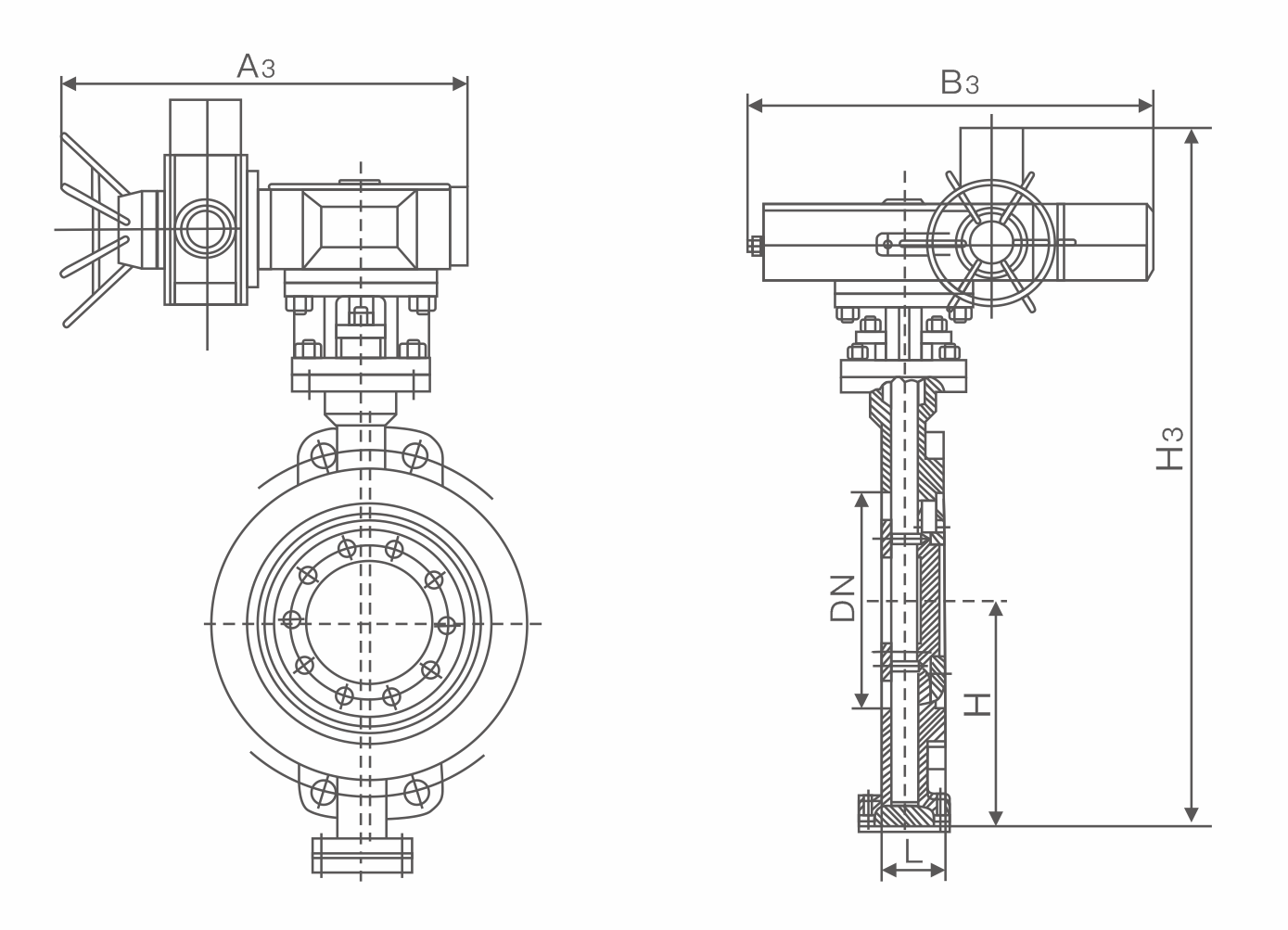

Main contour connection dimensions

|

(DN) |

main dimension |

flange dimensions |

||||||||||

| L | H | H1 | 1.0MPa | 1.6MPa | 2.5MPa | |||||||

| D | D1 | n-Фd | D | D1 | n-Фd | D | D1 | n-Фd | ||||

| 50 | 43 | 112 | 530 | 165 | 125 | 4-18 | 165 | 125 | 4-18 | 165 | 125 | 4-18 |

| 65 | 46 | 115 | 530 | 185 | 145 | 4-18 | 185 | 145 | 4-18 | 185 | 145 | 8-18 |

| 80 | 46 | 120 | 565 | 200 | 160 | 4-18 | 200 | 160 | 8-18 | 200 | 160 | 8-18 |

| 100 | 52 | 138 | 600 | 220 | 180 | 8-18 | 220 | 180 | 8-18 | 235 | 190 | 8-22 |

| 125 | 56 | 164 | 640 | 250 | 210 | 8-18 | 250 | 210 | 8-18 | 270 | 220 | 8-26 |

| 150 | 56 | 175 | 705 | 285 | 240 | 8-22 | 285 | 240 | 8-22 | 300 | 250 | 8-26 |

| 200 | 60 | 200 | 775 | 340 | 295 | 8-22 | 340 | 295 | 12-22 | 360 | 310 | 12-26 |

| 250 | 68 | 243 | 945 | 395 | 350 | 12-22 | 405 | 355 | 12-26 | 425 | 370 | 12-30 |

| 300 | 78 | 250 | 1070 | 445 | 400 | 12-22 | 460 | 410 | 12-26 | 485 | 430 | 16-30 |

| 350 | 78 | 280 | 1140 | 505 | 460 | 16-22 | 520 | 470 | 12-26 | 555 | 490 | 16-33 |

| 400 | 102 | 305 | 1210 | 565 | 515 | 16-26 | 580 | 525 | 16-26 | 620 | 550 | 16-36 |

| 450 | 114 | 350 | 1335 | 615 | 565 | 20-26 | 640 | 585 | 16-30 | 670 | 600 | 20-36 |

| 500 | 127 | 380 | 1415 | 670 | 620 | 20-26 | 715 | 650 | 20-30 | 730 | 660 | 20-36 |

| 600 | 154 | 445 | 1605 | 780 | 725 | 20-30 | 840 | 770 | 20-33 | 845 | 770 | 20-39 |

| 700 | 165 | 480 | 1844 | 895 | 840 | 24-30 | 910 | 840 | 24-36 | 960 | 875 | 24-42 |

| 800 | 190 | 530 | 2040 | 1015 | 950 | 24-33 | 1025 | 950 | 24-39 | 1085 | 990 | 24-48 |

| 900 | 203 | 580 | 2255 | 1115 | 1050 | 28-33 | 1125 | 1050 | 28-39 | 1185 | 1090 | 28-48 |

| 1000 | 216 | 650 | 2380 | 1230 | 1160 | 28-36 | 1255 | 1170 | 28-42 | 1320 | 1210 | 28-56 |

| 1200 | 254 | 760 | 2640 | 1455 | 1380 | 32-39 | 1485 | 1390 | 32-48 | 1530 | 1420 | 32-56 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333