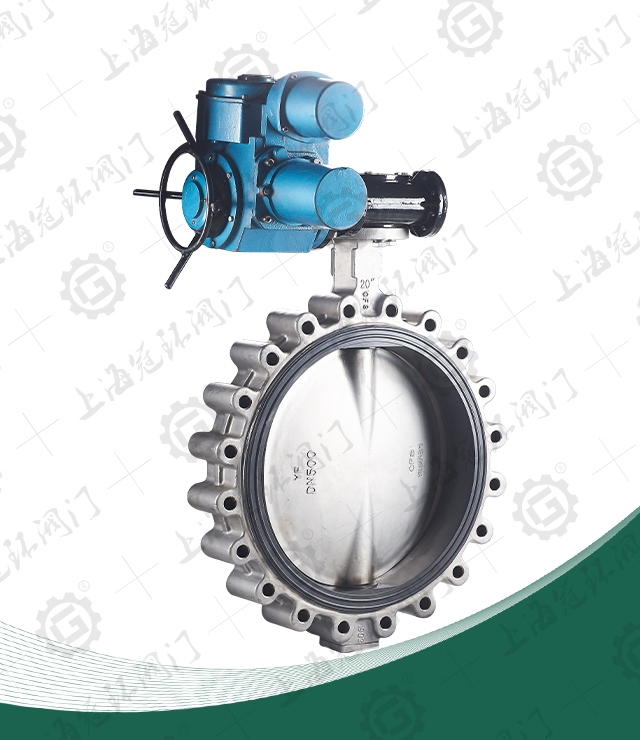

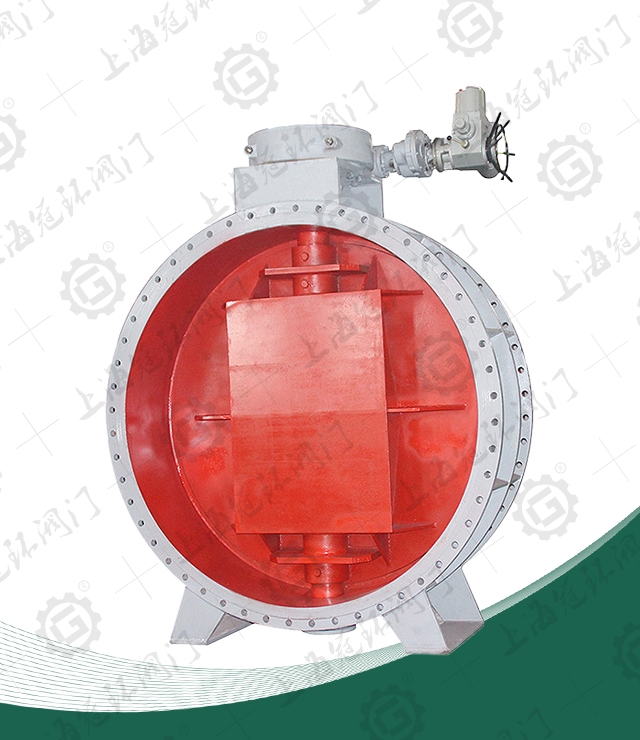

Electric stainless steel lug type butterfly valve

Product overview

Product characteristic

1, the shell is small and smooth, small size, light weight, simple wiring, beautiful and easy to move and maintain.

2, the performance is superior and stable, there are ordinary type, with potentiometer type, passive type, intelligent, fast close slow close, indicator display and so on everything.

3, low power loss rate, can save a lot of costs.

4, advanced technology, electronic parts using imported components stable performance, mechanical parts processing fine precision wear-resistant, with multiple protection devices to avoid improper operation or overload caused damage, manual electric device can be manually controlled at any time, compact structure optimization design to eliminate the lack of noise.

5, the intelligent integrated device has signal 4 ~ 20mA input and output, proportional adjustment control and positioning, no manual control, position self-locking, simple connection, stable and reliable performance, high control accuracy, fast reaction speed, etc.

6, it is very convenient to install on the valve, but it can be directly installed on the manual valve without mechanical processing.

7, the voltage is AC220V, DC220V, DC24, AC110V and other power supplies can be provided.

- Executive standard

|

design criterion |

GB/T12238-2008、ISO 10631-1994 or BS EN593-1998、BS5155、MSS SP-67 |

| flanged joint |

GB/T17241.6-2008、 JIS B2212-B2214-1999,JIS B2220-2004、JIS B2210-1984、ANSI B16.5-2009, ANSI B16.47-2006、ISO 7005-2 or BS EN 1092-2002(PN6、PN10、PN16、 Class 125、 Class150、5K、10K、 16K) |

|

structure length |

GB/T12221 -2005、IS0 5752-1988SBSEN558-1 |

|

pressure testing |

GB/T13927-2008、JB/T9092-1999、ISO 5028-1993或BS 5755-1-1986 |

|

Comply with ISO5211 and other standards |

Main contour connection dimensions

|

DN |

L | PN1.0MPa | PN 1.6MPa | H1 | H2 | H3 | H4 | K | E | ||||

| D1 | D2 | n-M | D1 | D2 | n-M | ||||||||

| 200 | 71 | 280 | 352 | 8-20 | 290 | 262 | 12-20 | 175 | 260 | 304 | 45 | 115 | 88.9 |

| 250 | 76 | 350 | 317 | 12-20 | 355 | 324 | 12-22 | 203 | 292 | 304 | 45 | 115 | 88.9 |

| 300 | 83 | 390 | 360 | 12-20 | 400 | 368 | 16-22 | 242 | 337 | 304 | 45 | 140 | 107.95 |

| 350 | 92 | 435 | 403 |

12-22 |

445 | 413 | 16-22 | 267 | 368 | 342 | 45 | 140 | 107.95 |

| 400 | 102 | 495 | 463 | 16-22 | 510 | 475 | 16-24 | 325 | 400 | 342 | 51.2 | 197 | 158.75 |

| 450 | 114 | 555 | 523 | 16-22 | 565 | 530 | 20-24 | 345 | 422 | 342 | 51.2 | 197 | 158.75 |

| 500 | 124 | 605 | 573 | 20-22 | 620 | 585 | 20-24 | 378 | 480 | 350 | 64.2 | 197 | 158.75 |

| 600 | 154 | 715 | 680 | 20-24 | 730 | 690 | 20-30 | 475 | 562 | 350 | 70.2 | 276 | 215.9 |

| 700 | 165 | 820 | 785 | 24-24 | 840 | 800 | 24-30 | 535 | 624 | 392 | 66 | 300 | 254 |

| 800 | 190 | 930 | 890 | 24-30 | 950 | 905 | 28-30 | 606 | 672 | 392 | 82 | 300 | 254 |

| 900 | 203 | 1030 | 990 |

24-30 |

1050 | 1005 | 28-30 | 670 | 720 | 417 | 118 | 300 | 254 |

| 1000 | 216 | 1130 | 1090 | 28-30 | 1160 | 1110 | 28-36 | 735 | 800 | 417 | 142 | 300 | 254 |

| 1200 | 254 | 1350 | 1305 | 32-30 | 1380 | 1325 | 32-36 | 878 | 940.7 | 496 | 150 | 350 | 298 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333