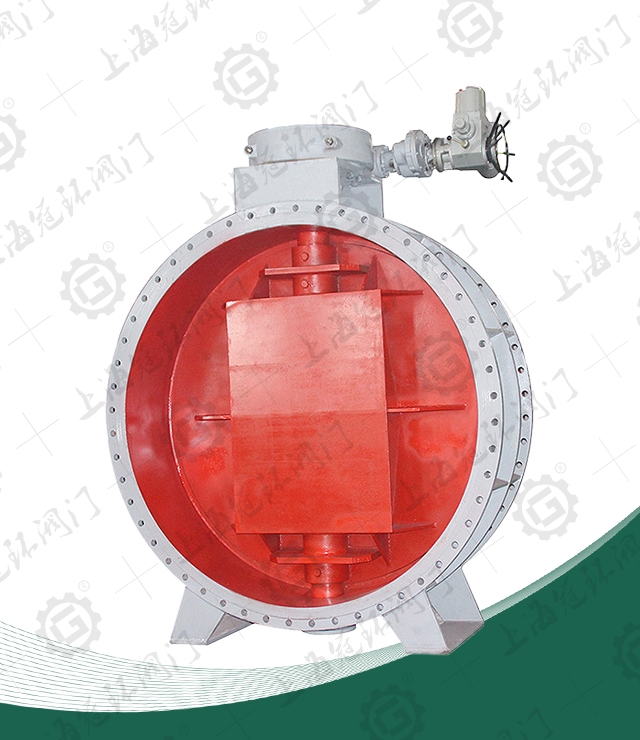

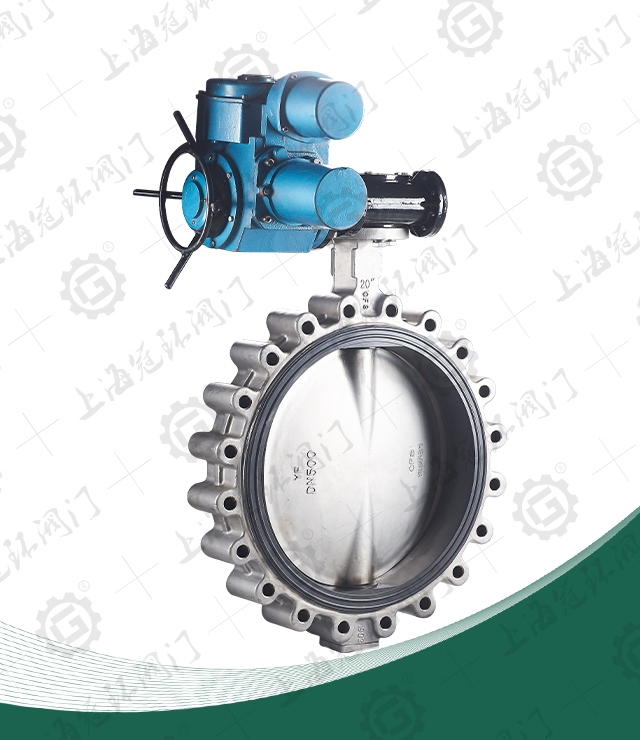

Electric eccentric half ball valve

Product overview

Product advantage

1, to solve the metallurgy, paper industry particles, powder, pulp and other media in the operation of precipitation, easy to scale, resulting in poor valve seal problems.

2, the switch is light, the ball is separated from the shell when it is opened, without any contact, the starting torque is small, and the rotation is flexible. When closed, the squeezing and cutting action between the hemisphere and the seat can remove the dirt on the sealing surface, so that the valve can be opened and closed smoothly, with high safety factor and good sealing performance.

3, the eccentric structure of the sealing surface, so that the sphere can automatically compensate for wear, can ensure the sealing performance of the valve, and will not leak, the use of this valve control pipeline safety performance is high.

4, the valve electric drive, very convenient, you can also choose the right torque according to the customer's working conditions, the brand of electric grip. Remote control can also be selected according to the working condition

Main shape and connection dimensions

|

PN(MPa) |

DN |

Size(mm) |

||||||||

|

L |

D Series 1/ Series 2 |

D1 |

D2 |

D6 |

b |

f |

Z-φd |

|||

|

mm |

in |

flange |

||||||||

|

1.0 |

40 |

- |

125 |

145 |

110 |

85 |

- |

16 |

3 |

4-18 |

|

50 |

- |

140 |

160 |

125 |

100 |

- |

16 |

3 |

4-18 |

|

|

65 |

- |

190 |

180 |

145 |

120 |

- |

18 |

3 |

4-18 |

|

|

80 |

- |

178 |

195 |

160 |

135 |

- |

20 |

3 |

4-18 |

|

|

100 |

- |

200 |

215 |

180 |

155 |

- |

20 |

3 |

8-18 |

|

|

125 |

- |

254 |

245 |

210 |

185 |

- |

22 |

3 |

8-18 |

|

|

150 |

- |

267 |

280 |

240 |

210 |

- |

24 |

3 |

8-23 |

|

|

200 |

- |

292 |

335 |

295 |

265 |

- |

24 |

3 |

8-23 |

|

|

250 |

- |

330 |

390 |

350 |

320 |

- |

26 |

3 |

12-23 |

|

|

300 |

- |

390 |

440 |

400 |

368 |

- |

26 |

4 |

12-23 |

|

|

350 |

- |

430 |

500 |

460 |

428 |

- |

28 |

4 |

16-23 |

|

|

400 |

- |

530 |

565 |

515 |

482 |

- |

28 |

4 |

16-25 |

|

|

450 |

- |

580 |

615 |

565 |

532 |

- |

30 |

4 |

20-25 |

|

|

500 |

- |

630 |

670 |

620 |

585 |

- |

30 |

4 |

20-25 |

|

|

600 |

- |

800 |

480 |

725 |

685 |

- |

34 |

5 |

20-30 |

|

|

700 |

- |

900 |

895 |

840 |

800 |

- |

38 |

5 |

24-30 |

|

|

800 |

- |

1000 |

1010 |

950 |

905 |

- |

42 |

5 |

24-34 |

|

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333