O-type shut-off valve (electric)

Nominal diameter: DN25~300mm

Pressure range: PN1.6~4.0MPa

Operating temperature: -29 ℃~200 ℃

Applicable media: syrup, fiber, granules, pulp

Flange standard: GB/T9113-2010

Structural form: floating ball valve

Valve material: stainless steel CF8

Drive mode: electric, intelligent, adjustable

The "O" type cut-off ball valve adopts a two piece ball valve structure for small diameters, and a three piece ball valve structure for large diameters. The valve body is composed of two parts: the main and auxiliary parts, and the ball core adopts a full diameter, with a high rated flow coefficient and low flow resistance. The surface of the ball core is hardened using a special process to make it smooth and wear-resistant. The sealing material of the valve seat is carbon fiber reinforced polytetrafluoroethylene, which has low wear of the valve seat, excellent sealing, long service life, and extremely strong cutting performance. The actuator adopts a high-performance dual piston gear rack structure or a fork type structure, with high transmission efficiency and compact structure, or an electronic electric actuator. This series of products has a nominal diameter range of DN15~500mm (1/2 "~20") and a nominal pressure rating of PN1.6~10.0MPa (150lb~600lb).

Product Features

Valve seat limiting structure (torque stability): The valve seat

sealing ring is reasonably pre tightened and limited, greatly reducing

operating torque; The bottom of the valve seat is equipped with a spring

to maintain torque stability;

Valve stem anti flying design (safe

and reliable): Bottom mounted valve stem prevents the valve stem from

flying out due to high medium pressure, completely eliminating safety

hazards;

Fire resistant design (can maintain sealing after fire):

The soft sealing valve seat adopts a stainless steel seat with a sealing

surface wrapped in a PTFE sealing ring combination valve seat, and

there is a small gap between the stainless steel seat sealing surface

and the ball. When the PTFE sealing ring is burned out by fire, the

floating ball is pressed against the stainless steel seat under the

pressure of the medium, and at the same time, it relies on the spring at

the bottom of the seat to push the stainless steel seat against the

ball core, forming a seal between the ball and the sealing surface of

the stainless steel seat;

Antistatic device (it can lead out static

electricity): a simple and easy to install Antistatic device, which

makes the ball, valve rod and valve body always connected, and the

static electricity generated by the friction of the sealing surface

caused by the switch is led out;

Standard actuators: pneumatic and electric interchangeable.

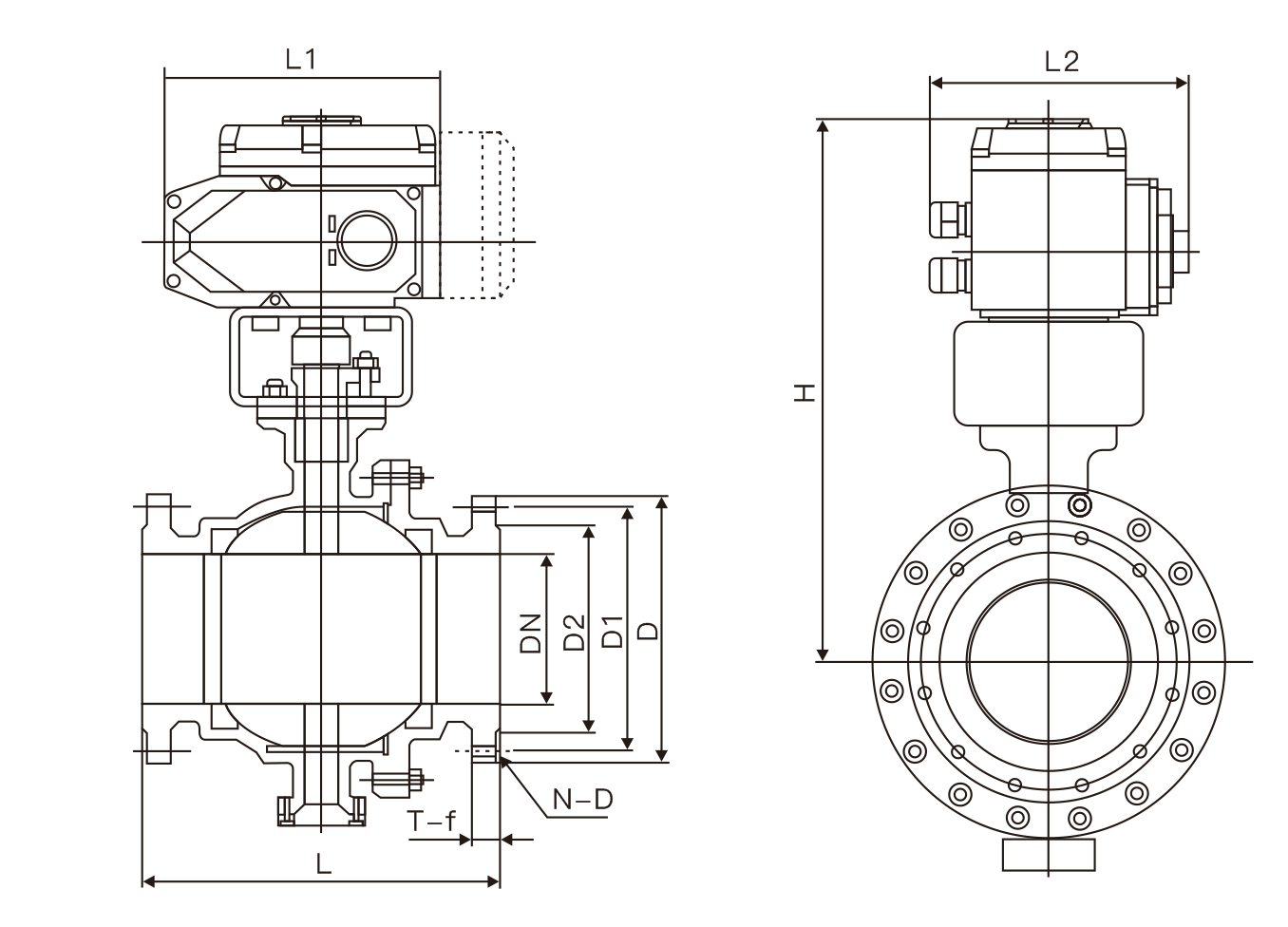

Main connect dimension

|

DN(mm) |

size(mm) |

||||||||

|

L |

L1 |

L2 |

H |

D |

D1 |

D2 |

b-f |

N-D |

|

|

50 |

178 |

190 |

170 |

290 |

165 |

125 |

102 |

18-3 |

4-18 |

|

65 |

190 |

270 |

220 |

330 |

185 |

145 |

122 |

18-3 |

8-18 |

|

80 |

203 |

270 |

220 |

345 |

200 |

160 |

138 |

20-3 |

8-18 |

|

100 |

229 |

270 |

220 |

355 |

220 |

180 |

158 |

20-3 |

8-18 |

|

125 |

356 |

270 |

220 |

385 |

250 |

210 |

188 |

22-3 |

8-18 |

|

150 |

394 |

270 |

220 |

405 |

285 |

240 |

212 |

22-3 |

8-22 |

|

200 |

457 |

270 |

220 |

430 |

340 |

295 |

268 |

24-3 |

12-22 |

|

250 |

533 |

270 |

220 |

465 |

405 |

355 |

320 |

26-3 |

12-26 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333