Electric stainless steel floating ball valve

Product overview

Product characteristics

1,

the fluid resistance is small, ball valve is a small fluid resistance

in all valve classes, even if it is a ball valve, its fluid resistance

is quite small.

2,

the thrust bearing reduces the friction torque of the valve stem, and

can be balanced and flexible for long-term operation using the valve

stem.

3,

the sealing performance of the seat is good, the sealing ring made of

polytetrafluoroethylene and other materials is easy to seal, and the

sealing capacity of the ball valve increases with the increase of the

pressure of the medium.

4,

the valve stem seal is reliable, because the valve stem only for

rotating movement without lifting movement, the filling seal of the

valve stem is not easy to destroy, and the sealing capacity increases

with the pressure of the medium.

5,

because the polytetrafluoroethylene material has good self-lubrication,

the friction loss with the ball is small, and the service life of the

ball valve is long.

6,

the lower mounted valve stem and valve stem head convex step to prevent

the valve stem ejecta, such as fire caused by the valve stem seal

damage, the convex step and the valve body can also form metal contact

to ensure the valve stem seal.

Material of main parts

|

part name |

materials | |||

|

vlave body |

WCB | 304(CF8) | 316(CF8M) | 316L(CF3M) |

|

ball body |

2Cr13+nitrogen treatment | 304 | 316 | 316L |

|

valve stem |

2Cr13 | 304 | 316 | 316L |

| valve seat insert |

PTFE(polytetrafluoroethylene)、PPL(Polyphenylene) |

|||

| padding | V-type PTFE PTFE packing, flexible graphite | |||

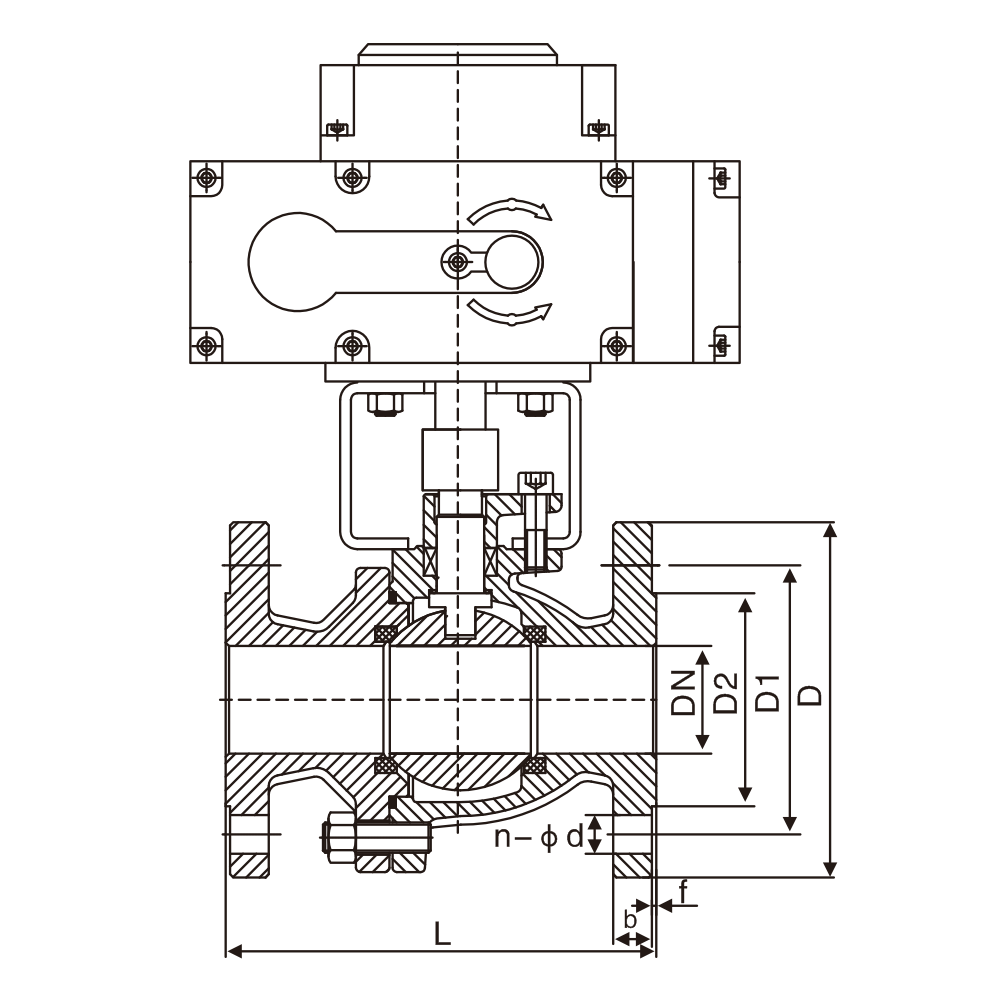

Main connection size

|

15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| L | 130 | 140 | 150 | 165 | 180 | 200 | 220 | 250 | 280 | 320 | 360 | 400 | 630 | 750 | |

| H | with PSQ | 275 | 280 | 287 | 312 | 312 | 325 | 335 | 365 | 400 | 420 | 440 | 470 | 545 | 580 |

| with HQ | 360 | 370 | 380 | 392 | 392 | 415 | 425 | 445 | 490 | 510 | 530 | 560 | 635 | 670 | |

| with 361R | 360 | 370 | 380 | 392 | 392 | 415 | 425 | 445 | 490 | 510 | 530 | 560 | 635 | 670 | |

| W | 157 | 157 | 157 | 157 | 208 | 208 | 256 | 256 | 256 | 256 | 256 | 256 | 380 | 380 | |

|

PN1.6MPa Flange connection size |

|||||||||||||||

| D | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 | |

| D1 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | |

| D2 | 46 | 56 | 65 | 76 | 84 | 99 | 118 | 132 | 156 | 184 | 211 | 266 | 319 | 370 | |

| n-φd | 4-14 | 4-14 | 4-14 | 4-18 | 4-18 | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-22 | 12-22 | 12-26 | 12-26 | |

| PN2.5MPa Flange connection size | |||||||||||||||

| D | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | 235 | 270 | 300 | 360 | 425 | 485 | |

| D1 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | |

| D2 | 46 | 56 | 65 | 76 | 84 | 99 | 118 | 132 | 156 | 184 | 211 | 274 | 330 | 389 | |

| n-φd | 4-14 | 4-14 | 4-14 | 4-18 | 4-18 | 4-18 | 8-18 | 8-18 | 8-22 | 8-26 | 8-26 | 12-26 | 12-30 | 16-30 | |

| PN4.0MPa Flange connection size | |||||||||||||||

| D | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | 235 | 270 | 300 | 375 | 450 | 515 | |

| D1 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 320 | 385 | 450 | |

| D6 | 40 | 51 | 58 | 66 | 76 | 88 | 110 | 121 | 150 | 176 | 204 | 260 | 313 | 364 | |

| n-φd | 4-14 | 4-14 | 4-14 | 4-18 | 4-18 | 4-18 | 8-18 | 8-18 | 8-22 | 8-26 | 8-26 | 12-30 | 12-22 | 16-33 | |

| PN6.3MPa Flange connection size | |||||||||||||||

| D | 105 | 130 | 140 | 155 | 170 | 180 | 205 | 215 | 250 | 295 | 345 | 415 | 470 | 530 | |

| D1 | 75 | 90 | 100 | 110 | 125 | 135 | 160 | 170 | 200 | 240 | 280 | 345 | 400 | 460 | |

| D6 | 40 | 51 | 58 | 66 | 76 | 88 | 110 | 121 | 150 | 176 | 204 | 260 | 313 | 364 | |

| n-φd | 4-14 | 4-18 | 4-18 | 4-22 | 4-22 | 4-22 | 8-22 | 8-22 | 8-26 | 8-30 | 8-33 | 12-36 | 12-36 | 16-36 | |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333