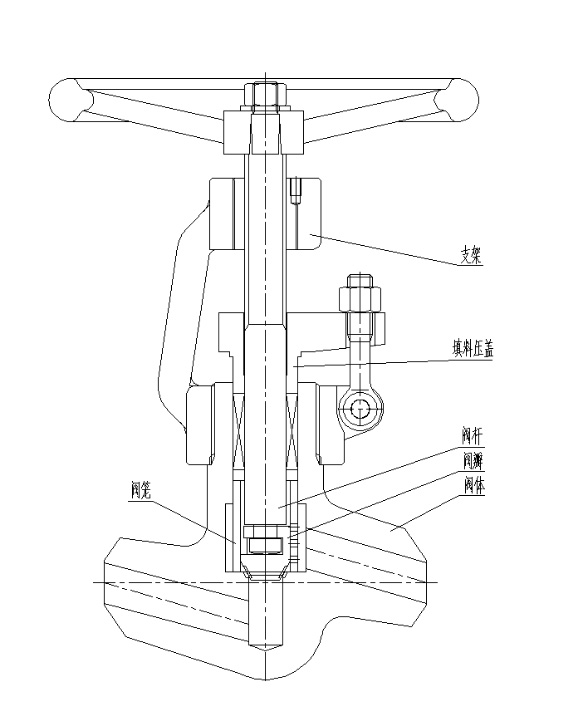

Anti-initializing globe valve

Nominal pressure: PN10-42.0mpa

Applicable media: steam, water, and corrosive media

Medium temperature: -50 ℃~700 ℃

1. When high-pressure medium enters the valve, it first depressurizes the valve cage to release pressure energy and noise, so that the fluid does not erode the sealing surface of the valve core and valve seat, thereby avoiding erosion. By moving the valve disc up and down, the flow rate of the valve can be adjusted arbitrarily, with adjustability.

2. High temperature, high pressure, and erosion resistance. The main components are made of high-quality stainless steel, and the sealing parts of the valve core and valve seat are welded with special processing technology of Stellite hard alloy. The welding layer on the sealing surface is not less than 2.5mm.

3. The contact between the valve disc and the valve cage does not generate friction, and the valve cage is positioned vertically, making the valve close tightly without leakage and open flexibly without jamming.

4. The valve stem and valve disc adopt a flexible structure, which can adjust problems such as scratches and leaks caused by non concentric valve stems during the manufacturing process.

5. The surface of the valve stem is treated with corrosion-resistant nitriding, which has good rigidity, wear resistance, and scratch resistance.

6. The filler is flexible graphite with nickel wire added inside, which is soft and wear-resistant and will not scratch the valve stem.

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333