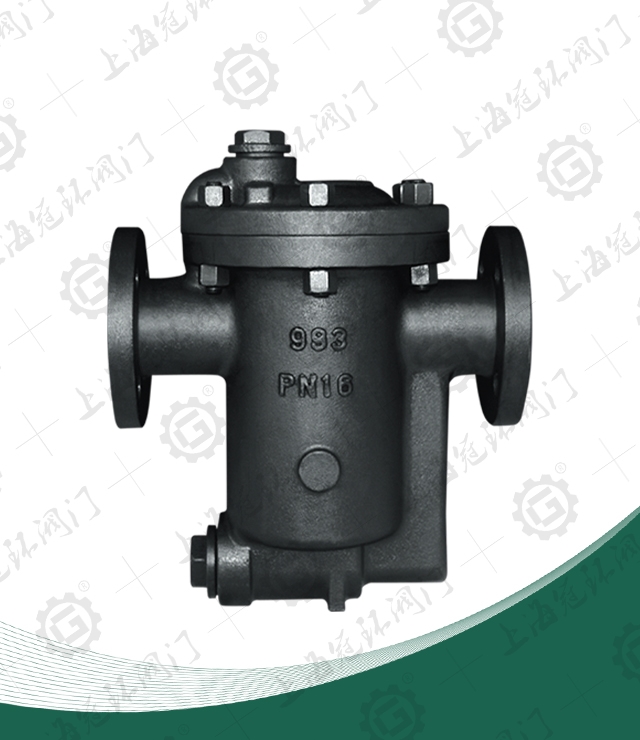

Bell float steam trap

Nominal diameter: DN15~50mm

Nominal pressure: 0.1-1.6MPa

Working temperature: ≤350°C

Main material: cast steel, stainless steel

Drive mode: manual

Product overview

Bell float steam traps are used

in steam mains, split cylinders, heat exchangers, vulcanizing presses,

hot air dryers, cylindrical dryers, stills, concentration units, etc.

The compact and lightweight ES5 type is suitable for air conditioners,

washing machines, sound dyeers, etc. The all-stainless steel ESU5 type

is used for food industry and steam equipment. The valve is mainly used

in chemical, petrochemical, petroleum, papermaking, mining, electric

power, liquefied gas, food, water supply and drainage, municipal,

mechanical equipment supporting, electronic industry, urban construction

and other fields.

Features and performance

1. Strong adaptability to the amount of condensate, intermittent discharge, and continuous discharge.

2. The SCCV closing system is reasonably designed to compensate for the

error generated by the lever machinery and avoid the rigid collision

when closing.

3. The internal parts are made of stainless steel and

installed on the valve cover, which is convenient for maintenance and

maintenance.

4. The back pressure rate is high.

5. Reliable

separation of steam and water (water vapor enters from the lower part of

the valve through the U-shaped channel), and the valve is in a

water-sealed state to prevent steam leakage.

6. The mouth-shaped

float resists water shock. The bucket is equipped with an overflow

exhaust hole to prevent steam lock and air blockage. (Non-condensable

hot air can also be excluded).

Main shape and connection size

| Product number | Nominal diameter DN | connect Way | Working pressure range (MPa) | temperature limit℃ | Body material | Material of main parts | Dimensions(mm) | |||

| L | H1 | H2 | W | |||||||

| ER105 | 20~40 | internal thread | 0.01~0.3~0.7 | 220 | WCB | SUS | 200 | 160 | 135 | - |

| (CS15H-3.7) | (3Cr13) | |||||||||

| ER105F | 15~25 | flange | 0.01~0.3~0.7 | 220 | WCB | SUS | 270 | 160 | 135 | - |

| (CS45H-3.7) | 32~50 | (3Cr13) | ||||||||

| ER110 | 15~25 | flange | 0.01~0.5~1.2 | 220 | WCB | SUS | 310 | 160 | 131 | - |

| (CS45H-5.12) | 32~50 | (3Cr13) | 165 | 167 | ||||||

| ER116 | 15~25 | flange | 0.01~0.7~1.6 | 220 | WCB | SUS | 310 | 160 | 131 | - |

| (CS45H-7.16) | 32~50 | (3Cr13) | 165 | 167 | ||||||

| ER120 | 40~65 | flange | 0.05~0.8~1.6 | 220 | WCB | SUS | 420 | 175 | 214 | - |

| (CS45H-8.16) | (3Cr13) | |||||||||

| ER25 | 15~50 | flange | 0.05~2.5~4.5~6.5 | 425 | WCB | SUS | 380 | 210 | 180 | 345 |

| (CS45H-25 | (3Cr13) | |||||||||

| ER105 | 15~50 | socket welding | 0.05~2.5~4.5~6.5 | 425 | WCB | SUS | 380 | 210 | 180 | 345 |

| (CS45H-25 | (3Cr13) | |||||||||

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333