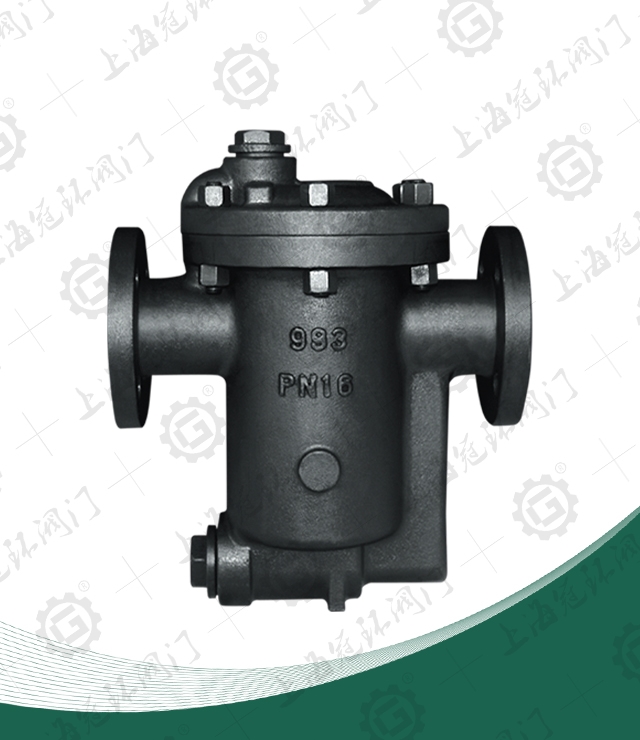

Inverted bucket steam trap (ES8F)

Product overview

Working principle

Inverted bucket steam trap It is the use of condensate and steam density difference working principle, the internal structure is connected by the lever system inverted bucket, to overcome the steam pressure switch inverted bucket trap inside is an inverted bucket for liquid level sensitive parts, inverted bucket opening down. When the device is just started, there is air and low-temperature condensate in the pipeline, at this time the trap is fully open, the air and low-temperature condensate are quickly discharged, and the device quickly raises the temperature. When the steam enters the inverted bucket, the inverted bucket generates upward buoyancy, and the inverted bucket is connected to a lever to drive the valve core to close the valve. There is a small hole on the inverted bucket, which can automatically exhaust air. When one part of the steam is discharged from the small hole, the other part of the steam produces condensate, and the inverted bucket loses its buoyancy and sinks. The inverted bucket is connected with a lever to drive the valve core to open the valve. When the steam enters the inverted bucket again, the valve is closed again, and the cycle work and intermittent drainage.

-

Dimensions

- Body Material

|

|

|

Use pressure patterns (Mpa) |

|

|

||||

| L | H1 | H2 | W | ||||||

|

ES8B (CS15H-5·8·16) |

15 20 25 |

ZG1/2"~1" |

0.01~0.5·0.8·1.6 | 220 | WCB | 138 | 72 | 94 | 103 |

|

ES8N (CS15H-5·8·16) |

15 20 25 |

ZG1/2"~1" |

0.01~0.5·0.8·1.6 | 220 | WCB | 138 | 72 | 94 | 103 |

|

ES8BF (CS45H-5·8·16) |

15 20 25 |

flange | 0.01~0.5·0.8·1.6 | 220 | WCB | 210 | 72 | 94 | 103 |

|

ES8NF (CS45H-5·8·16) |

15 20 25 |

flange | 0.01~0.5·0.8·1.6 | 220 | WCB | 210 | 72 | 94 | 103 |

|

ES10 (CS15H-8·12·16) |

20~40 |

ZG1/2"~1" |

0.01~0.8·1.2·1.6 | 220 | WCB | 200 | 93 | 132 | 142 |

|

ES10F (CS45H-8·12·16) |

15~25 32~50 |

flange | 0.01~0.8·1.2·1.6 | 220 | WCB | 270 | 93 | 132 | 142 |

|

ES12N (CS45H-16) |

15~25 32~50 |

flange | 0.01~1.6 | 200 | WCB | 280 | 93 | 132 | 142 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333