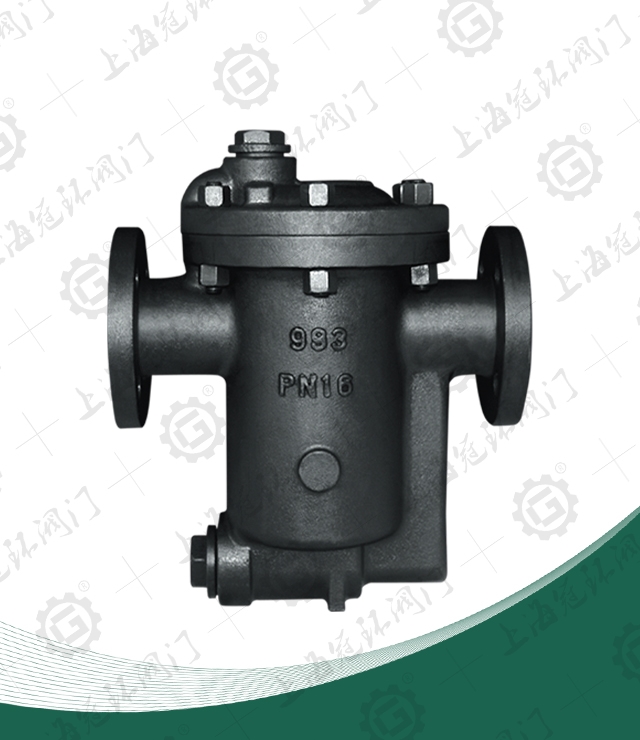

Threaded Inverted Bucket Steam Traps

Nominal diameter: DN15~50mm

Nominal pressure: PN1.6~4.0MPa

Working temperature: ≤350°C

Main materials: forged steel, stainless steel, titanium alloy steel, chromium molybdenum steel, low temperature steel

Drive mode: manual

Design specification: GB/T 9093

How it works

The inverted bucket steam trap uses

the working principle of the density difference between condensate and

steam, the internal structure is connected by a lever system to the

inverted bucket, overcome the steam pressure switch, and the inside of

the inverted bucket trap is an inverted bucket for the level sensitive

parts, and the opening of the inverted bucket is downward. When the unit

is first started, air and low-temperature condensate appear in the

pipe, and the trap is fully open, the air and low-temperature condensate

are quickly discharged, and the device quickly increases the

temperature. When the steam enters the inverted barrel, the inverted

barrel generates upward buoyancy, and the inverted barrel is connected

to the lever to drive the valve core to close the valve. There is a

small hole on the inverted bucket, which can automatically exhaust air,

when a part of the steam is discharged from the small hole, the other

part of the steam produces condensate, the inverted bucket loses

buoyancy and sinks, and the inverted bucket is connected to the lever to

drive the valve core to open the valve. When the steam enters the

inverted bucket again, the valve closes again, circulates and drains

intermittently.

Structural features

1.

Simple structure, not easy to fail. No latch or hinge structure, no

fixed wear, good energy-saving effect. Wear-resistant chromium steel

valve seat, stainless steel structure, long service life;

2. Intermittent discharge of impurities can be washed away, no dirt accumulation, automatic air exhaust;

3. There are a variety of orifice options, under different pressures, higher drainage flow can be achieved;

4. The internal parts are all installed on the valve cover, which is convenient for maintenance.

Main Dimensions

| model | The way to | L | H | H1 | Φ |

| 980 | DN15-DN25 | 125 | 180 | 102 | 103 |

| 981 | DN15-DN25 | 125 | 180 | 102 | 103 |

| 982 | DN20-DN25 | 170 | 238 | 130 | 145 |

| 983 | DN32-DN40 | 205 | 322 | 192 | 178 |

| 984 | DN32-DN40 | 235 | 380 | 212 | 203 |

| 985 | DN40-DN50 | 255 | 416 | 252 | 220 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333