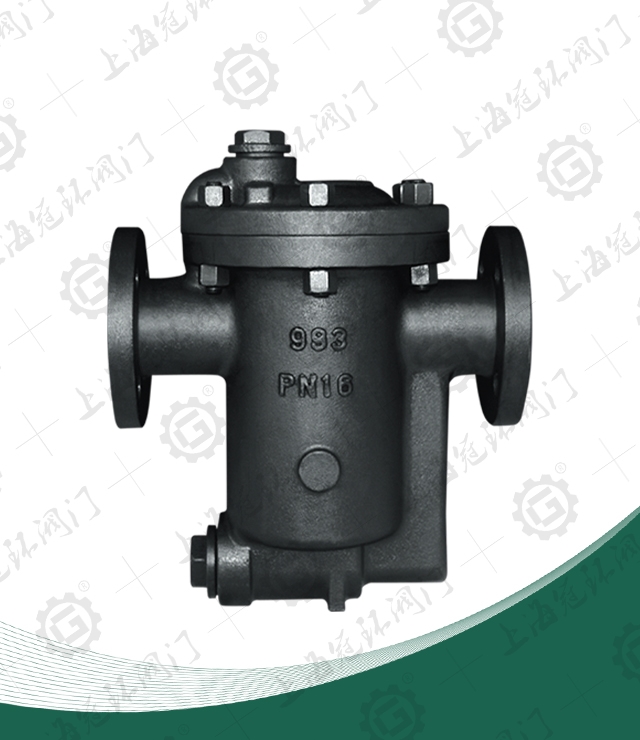

Thermostatic Capsule Steam Traps

Nominal diameter: DN15~50mm

Nominal pressure: PN1.6MPa

Working temperature: ≤350°C

Main materials: forged steel, stainless steel, titanium alloy steel, chromium molybdenum steel, low temperature steel

Drive mode: manual

Design specification: GB/T 9093

Structure length: GB/T 12250

Threaded connection: ISO 228

Flange connection: JB/T 79, GB 9113, ANSI B16.34

Test and inspection: GB/T 13927

Product overview

The

main operating element of the thermostatic membrane cartridge steam

trap is the metal membrane box, which is filled with a liquid with a

lower gasification temperature than the saturation temperature of water,

and the opening temperature is 15°C and 30°C below the saturation

temperature. Membrane cartridge traps are particularly responsive, not

afraid of freezing, small in size, resistant to overheating, and can be

installed in any position. The back pressure rate is greater than 80%,

can discharge non-condensing gas, the membrane box is solid, long

service life, easy maintenance, and a wide range of use. Ideal for

systems including heating steam mains, heat trace lines, dryers and

industrial heating steam plants.

Structural features

1. Excellent exhaust air capacity, can withstand superheated steam and water hammer.

2. In the pressure range, there is a fixed subcooling cycle operation.

3.

The valve is equipped with membrane box, including single group, double

group and multiple groups. Suitable for large displacement occasions.

4. Temperature sensing element, strong corrosion resistance, so that the life of this valve is durable.

5.

This piece has two kinds of carbon steel and stainless steel, small and

lightweight, vertical installation effect is better, and can also be

installed at any angle.

Main Dimensions

| Product model | diameter (mm) | Connection method | Body material | Working pressure range(MPa) | allowable temperature℃ | Dimensions (mm) | |||

| L | H1 | H2 | W | ||||||

| CS16H-16C | 15-20 | internal thread | WCB | 0.01~1.6 | 250 | 100 | 58 | 55 | 70 |

| 25 | 0.01~1.6 | 250 | 120 | 58 | 55 | 70 | |||

| 32-40 | 0.01~1.6 | 250 | 150 | 68 | 68 | 90 | |||

| 50 | 0.01~1.6 | 250 | 160 | 68 | 68 | 90 | |||

| CS46H-16C | 15-20 | flange | WCB | 0.01~2.5 | 250 | 150 | 58 | 55 | 70 |

| 25 | 0.01~2.5 | 250 | 160 | 58 | 55 | 70 | |||

| 32-50 | 0.01~2.5 | 250 | 210 | 85 | 60 | 120 | |||

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333