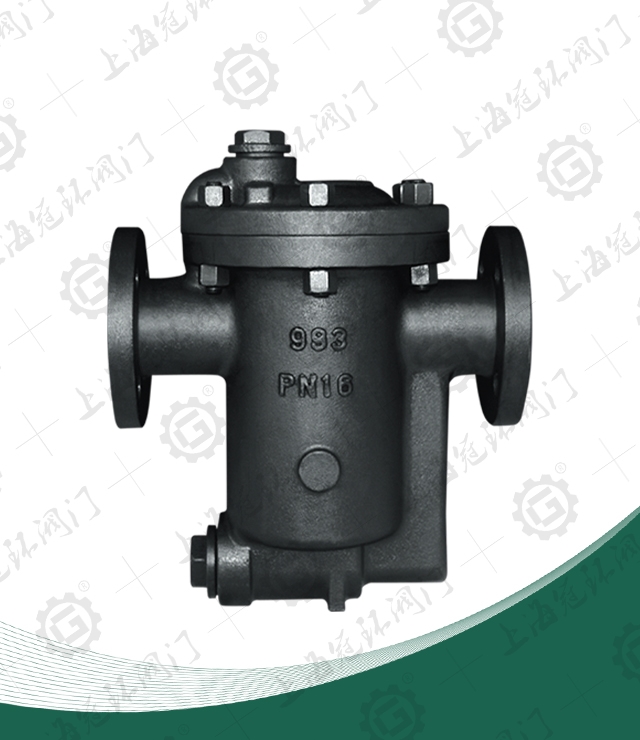

Vertical free float type steam trap

Working principle

CS41H-3NL vertical free float trap has a simple structure, and there is only one stainless steel hollow float inside, which is both a float and a opening and closing part, no vulnerable parts and long service life. When the device is just started, there is air and low temperature condensed water in the pipeline, the bimetal automatic air exhaust element pushes the float ball away from the seat, the valve is opened, and the non-condensible gas is removed. The low temperature condensed water flows into the trap, the float ball rises, and the condensed water is quickly discharged. The device quickly raises the temperature, and before the temperature in the pipeline rises to the saturation temperature, the temperature variation type of the bimetal automatic air exhaust element is extended; The steam trap enters the normal operation condition, and the float ball rises and falls with the liquid level to adjust the flow rate of the valve hole; When the condensate stops entering, the float approaches the valve seat with the flow of the medium and closes the valve. The seat of the vertical free float steam trap is always below the liquid level to form a water seal without steam leakage.

Product characteristics

Main connection size

| Model |

|

|

|

|

|

H |

L |

|||

|

CS11H-16-ⅠL |

15 |

|

120 |

84 |

|

20 |

120 |

84 |

||

|

25 |

120 |

84 |

||

|

CS41H-16-ⅠL |

15 |

|

150 |

84 |

|

20 |

150 |

84 |

||

|

25 |

150 |

84 |

||

|

CS11H-16-ⅡL |

15 |

|

160 |

170 |

|

20 |

160 |

170 |

||

|

25 |

160 |

170 |

||

|

CS41H-16-ⅡL |

15 |

Flange |

210 |

195 |

|

20 |

210 |

195 |

||

|

25 |

210 |

195 |

||

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333