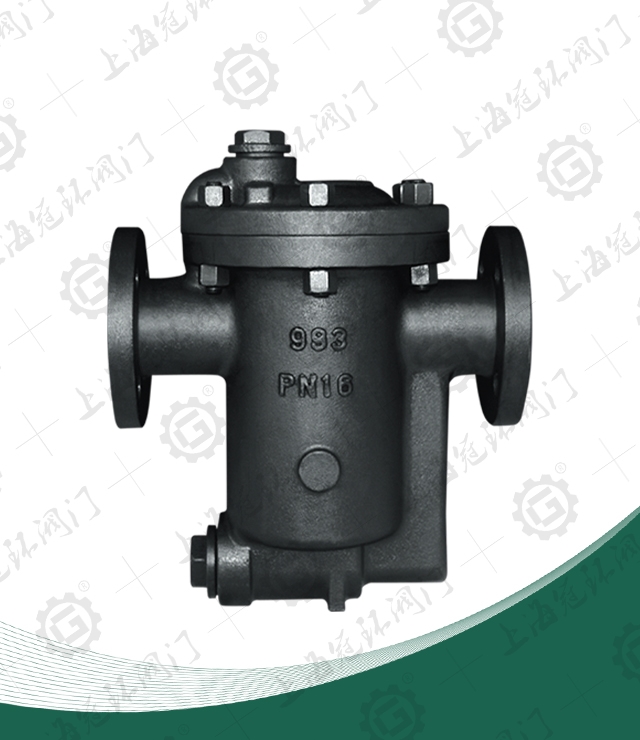

Bimetal Trap

Nominal diameter: DN15~50mm

Nominal pressure: PN1.6MPa

Working temperature: ≤ 350 ℃

Main materials: forged steel, stainless steel, titanium alloy steel, chromium molybdenum steel, low-temperature steel

Drive mode: manual

Product overview

The operating principle of the

adjustable bimetal trap is that the bimetal temperature sensing element

drives the valve core to open and close the valve. When the device is

just started, low-temperature condensate appears in the pipe, the

bimetal is flattened, and the spool is in the open position under the

spring force. When the condensate temperature gradually increases, the

bimetal temperature sensing element begins to bend and deform, and

pushes the valve core to the closed position. The trap closes completely

before the condensate reaches saturation temperature. There is always

high-temperature condensate in front of the valve, no steam leakage, and

the energy-saving effect is good.

Scope of application

Adjustable bimetal traps are used in steam mains, split cylinders,

steam trace lines, radiators, cryogenic heating baths, chip clamps, and

more.

Features and performance

1. New SCCV closing system design, reliable closing and long service life.

2.

The discharge temperature can be adjusted, and the sensible heat in the

high-temperature condensed water can be effectively used, and the

energy-saving effect is remarkable.

3. The discharge temperature can be measured when the pipe network is running, and it can be installed at any angle.

4. There is always high-temperature condensed water in front of the valve, forming a reliable water seal without steam leakage.

5. Anti-water hammer, excellent air exhaust performance.

6. There is no noise during operation, which is beneficial to protect the environment.

7.

At the beginning of steam ventilation, all valves are opened, and

low-temperature condensed water and air are quickly removed.

Significantly reduces device startup time.

8. The internal parts are all made of stainless steel, which is anti-corrosion and cavitation.

Main appearance and connection dimensions

| Product model | Nominal diameter (DN) | connection method | use pressure (MPa) | allowable temperature(℃) | Adjust temperature range(℃) | Dimensions | reference weight (Kg) | |||

| L | H1 | H2 | W | |||||||

| TB6 | 15~20 | thread | 0.01~1.6 | 220 | 50~180 | 90 | 108 | 25 | 63 | 1.8 |

| 25 | 95 | |||||||||

| TB6F | 15~20 | flange | 0.01~1.6 | 220 | 50~180 | 150 | 108 | 25 | 63 | 3.2 |

| 25 | 160 | 3.9 | ||||||||

| 32~50 | 230 | 5.6 | ||||||||

| TB6W | 15~20 | Socket welding | 0.01~1.6 | 220 | 50~180 | 90 | 108 | 25 | 63 | 1.8 |

| 25 | 95 | |||||||||

| TB11 | 15~20 | thread | 0.01~1.6 | 220 | 50~190 | 90 | 108 | 25 | 63 | 1.8 |

| 25 | 95 | |||||||||

| TB11F | 15~20 | flange | 0.01~1.6 | 220 | 50~190 | 150 | 108 | 25 | 63 | 3.2 |

| 25 | 160 | 3.9 | ||||||||

| 32~50 | 230 | 5.6 | ||||||||

| TB11W | 15~20 | socket welding | 0.01~1.6 | 220 | 50~190 | 90 | 108 | 25 | 63 | 1.8 |

| 25 | 95 | |||||||||

| TB3 | 15~20 | thread | 0.01~1.6 | 350 | 50~190 | 80 | 90 | 23 | 56 | 1.5 |

| 25 | 85 | |||||||||

| TB3F | 15~20 | flange | 0.01~1.6 | 350 | 50~190 | 150 | 90 | 23 | 56 | 3.3 |

| 25 | 160 | 4.2 | ||||||||

| TB3W | 15~20 | Socket welding | 0.01~1.6 | 350 | 50~190 | 80 | 90 | 23 | 56 | 1.5 |

| 25 | 85 | |||||||||

| TB5 | 15~20 | thread | 0.01~2.1 | 350 | 50~200 | 80 | 90 | 23 | 56 | 1.5 |

| 25 | 85 | |||||||||

| TB5F | 15~20 | flange | 0.01~2.1 | 350 | 50~200 | 150 | 90 | 23 | 56 | 3.3 |

| 25 | 160 | 4.2 | ||||||||

| TB5W | 15~20 | socket welding | 0.01~2.1 | 350 | 50~200 | 80 | 90 | 23 | 56 |

1.5 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333