Noise check valve

Nominal pressure: PN1.0~1.6MPa

Nominal pass through: DN40~600mm

Applicable medium: water and weak corrosive fluid

Applicable temperature: 0~80℃

Flange standard: GB/T 17241.6, GB/T 9113

Test standard: GB/T 13927, API 598

The energy-saving muffler check valve is suitable for water supply and drainage pipelines. The valve disc is guided by the central axis at both ends of the inlet. It can be opened and closed flexibly and can be installed horizontally or vertically. The valve disc is spring loaded, its quick closing can effectively eliminate water hammer, the sealing performance is good, and the closing is silent. It has the advantages of small size, light weight, low fluid resistance, fatigue resistance and long life.

Structural features

1. The inner cavity of the valve body adopts a streamlined design, and the flow rate is designed according to the standard to reduce sharp bends, corners, and sharp protrusions, thereby reducing the resistance of the fluid.

2. The front and rear of the valve disc are designed to be tapered, which greatly reduces the fluid resistance and reduces the noise caused by turbulent flow.

3. The closing stroke of the valve disc is short, only 1/4 of the nominal diameter, which reduces the closing time of the valve disc and reduces the generation of water hammer.

4. The valve uses a spring to accelerate the closing speed of the valve disc and reduce the generation of water hammer.

5. The valve disc is a hollow thin shell structure, which reduces the inertia of the valve disc, which not only enables the valve disc to start quickly when it is closed, but also reduces the impact noise when it is closed.

6. This product can be installed vertically, horizontally, obliquely and at any angle.

7. This product has compact structure, few parts, small volume, light weight and beautiful appearance.

8. The inner and outer surfaces are sprayed with environmental protection coating to ensure the anti-corrosion and safety of the product.

Main performance specifications

| Model | Nominal pressure | Shell test pressure | Seal test pressure | Applicable media | Operating temperature |

| H41X一10 | 1.0MPa | 1.5 MPa | 1.1 MPa | Water and weak corrosive fluids | 0~80℃ |

| H41X一16 | 1.6 MPa | 2.4 MPa | 1.76 MPa | Water and weak corrosive fluids | 0~80℃ |

Main part material

| Model | Body | Seal | Spring |

| H41X-10 | Cast iron or stainless steel | Nitrile rubber (NBR) | Stainless steel wire 1Cr18Ni9Ti |

| H41X-16 | Cast steel or stainless steel | Nitrile rubber (NBR) | Stainless steel wire 1Cr18Ni9Ti |

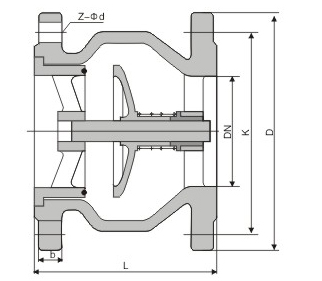

Main external connection dimensions

| Nominal pressure | Nominal diameter | Size(mm) | ||||

| L | D | K | b | Z-Φd | ||

| 1.0 | 40 | 112 | 145 | 110 | 18 | 4-18 |

| 50 | 120 | 160 | 125 | 20 | 4-18 | |

| 65 | 130 | 180 | 145 | 20 | 4-18 | |

| 80 | 150 | 195 | 160 | 22 | 8-18 | |

| 100 | 165 | 215 | 80 | 24 | 8-18 | |

| 125 | 190 | 245 | 210 | 26 | 8-18 | |

| 150 | 210 | 280 | 240 | 26 | 8-22 | |

| 200 | 255 | 335 | 295 | 28 | 8-22 | |

| 250 | 310 | 390 | 350 | 28 | 12-22 | |

| 300 | 320 | 440 | 400 | 28 | 12-22 | |

| 350 | 380 | 500 | 460 | 30 | 16-22 | |

| 400 | 405 | 565 | 515 | 32 | 16-26 | |

| 450 | 430 | 615 | 565 | 32 | 20-26 | |

| 500 | 450 | 670 | 620 | 34 | 20-26 | |

| 600 | 510 | 780 | 725 | 36 | 20-30 | |

| 1.6 | 40 | 112 | 145 | 110 | 18 | 4-18 |

| 50 | 120 | 160 | 125 | 20 | 4-18 | |

| 65 | 130 | 180 | 145 | 20 | 4-18 | |

| 80 | 150 | 195 | 160 | 22 | 8-18 | |

| 100 | 165 | 215 | 180 | 24 | 8-18 | |

| 125 | 190 | 245 | 210 | 26 | 8-18 | |

| 150 | 210 | 280 | 240 | 26 | 8-22 | |

| 200 | 255 | 335 | 295 | 30 | 12-22 | |

| 250 | 310 | 405 | 355 | 32 | 12-26 | |

| 300 | 320 | 460 | 410 | 32 | 12-26 | |

| 350 | 380 | 520 | 470 | 36 | 16-26 | |

| 400 | 405 | 580 | 525 | 38 | 16-30 | |

| 450 | 430 | 640 | 585 | 40 | 20-30 | |

| 500 | 450 | 715 | 650 | 42 | 20-33 | |

| 600 | 510 | 840 | 770 | 48 | 20-36 | |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333