Electric two-way valve

Input control signal: 4-20mA DC, input impedance 250 Ω

Position feedback potentiometer: 1K

Valve position output signal: 4-20mA DC, load resistance 0-250 Ω

The positive and reverse rotation of control motor adopts zero crossing triggering bidirectional silicon controlled rectifier

Deadband: 0.5-3% continuously adjustable. Production set to 1%

Interruption protection of input control signal: the valve position can be selected to stop, fully open and fully close as required

Power supply: 220VAC 50HZ

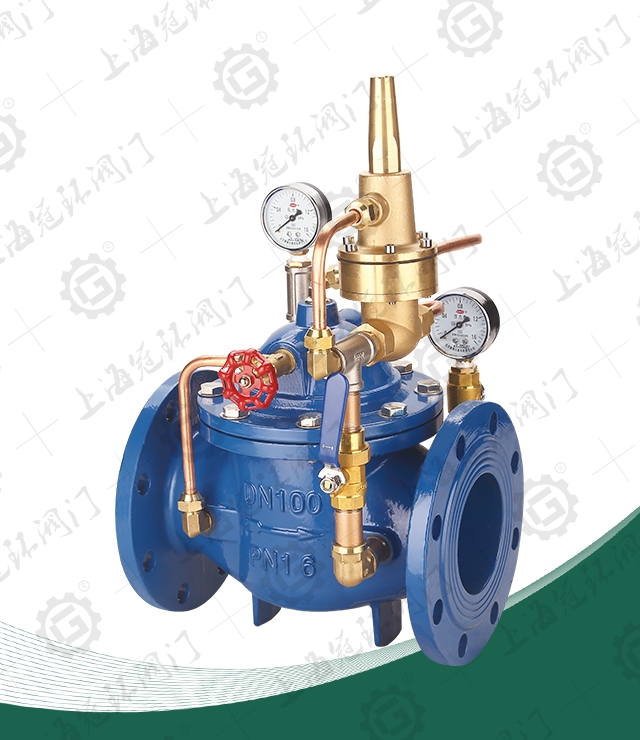

VB3000 electric two-way valve is a supporting product of central air conditioner fan coil, which is composed of driver and valve body. The driver is driven by a synchronous motor and has the functions of spring return and manual valve opening lever operation. The valve body adopts piston structure. The electric valve can be used together with the temperature controller. The temperature controller controls the motor of the electric valve to open or close the valve, so that the cold water or hot water in the pipeline can be connected or disconnected, and then the air can be supplied through the fan coil to achieve automatic temperature regulation.

Product features

1. It is used to control the opening or closing of cold water or hot water air-conditioning system pipes to control room temperature.

2. The driver is driven by a single hysteresis synchronous motor. The valve spring returns. When the valve does not work, it is in a normally closed state. When it needs to work, the temperature controller provides an open signal to enable the electric valve to connect to the AC power supply and act.

3. Open the valve, and the chilled water or hot water enters the fan coil to provide air conditioning or heating for the room. When the room temperature reaches the set value of the temperature controller, the temperature controller will power off the electric valve, and the reset spring will close the valve, so as to cut off the water flow into the fan coil. Close and open the valve to keep the room temperature within the temperature range set by the temperature controller.

4. The actuator and valve of the electric valve are connected by thread. The actuator can be installed after the valve is installed. Field assembly, flexible and convenient wiring. The plane design of the driver can be installed close to the wall, with small space occupation, reliable and durable products, low working noise, and reliable operation in the high temperature and humidity environment that often occurs in the concealed fan coil unit.

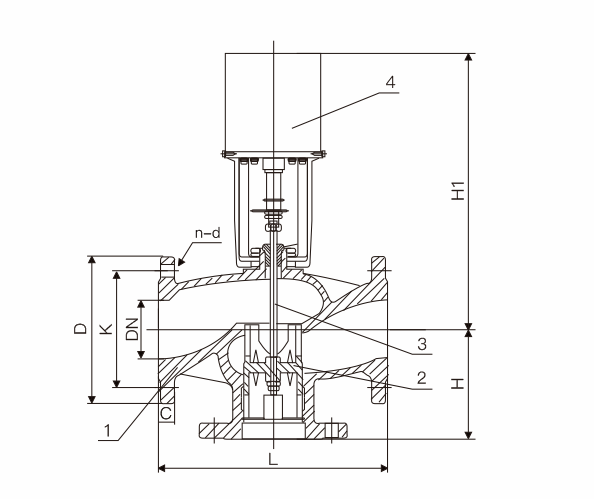

Main overall dimensions

|

Body size |

DN80 |

DN100 |

DN125 |

DN150 |

DN200 |

DN250 |

DN300 |

DN350 |

|

Length(L) |

290 |

320 |

340 |

375 |

395 |

460 |

500 |

570 |

|

Height(H1) |

600 |

620 |

630 |

650 |

830 |

850 |

950 |

980 |

|

Number of flange holes (n) |

8 |

8 |

8 |

8 |

12 |

12 |

12 |

12 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333