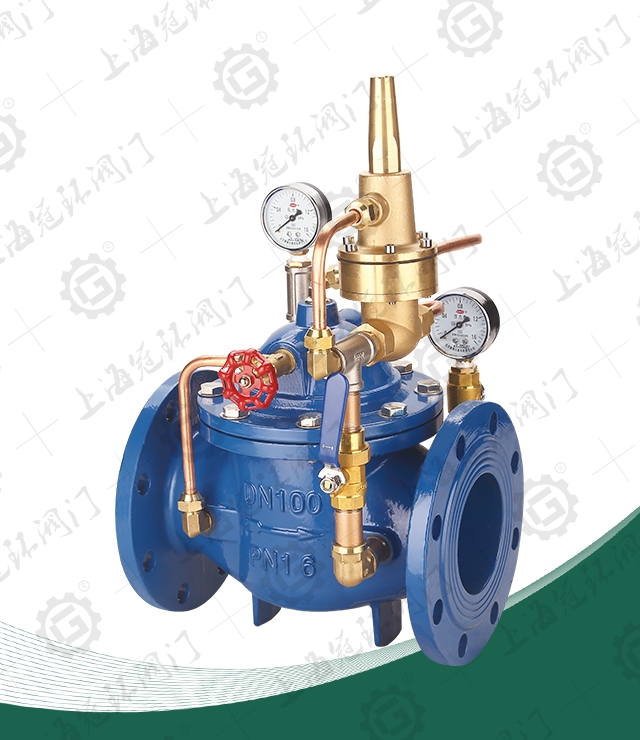

Double port exhaust valve

Nominal diameter: DN40~400mm

Nominal pressure: PN1.0~1.6MPa

Applicable temperature: 0 ° C~80 ° C

Applicable medium: water

When it is necessary to exhaust the gas in the pipeline, the valve stem should be rotated counterclockwise to raise it together with the valve, allowing the air in the pipeline to enter the body cavity under the pressure of water and be discharged from the exhaust nozzle. Then, the water in the pipeline fills the body cavity, causing the floating ball to move upward under the buoyancy of water to block the exhaust nozzle, achieving self sealing. The pipeline is in normal operation, and the air in the water is under the pressure, Continuously discharge into the upper part of the exhaust valve chamber, forcing the floating ball to descend and leave the original sealing position. At this time, air is discharged from the exhaust nozzle, and then the floating ball returns to its original position and self seals. Therefore, the exhaust valve is always open during normal operation, and the floating ball repeatedly repeats the above actions, causing air to continuously exhaust. When maintenance or cleaning of the body chamber is necessary, the valve should be closed. This exhaust valve is closed when the valve stem is rotated clockwise.

1. Able to eliminate gas in pipelines, reduce resistance, and save energy.

2. When the pipeline is under negative pressure, this product can quickly and automatically inhale air to prevent pipeline rupture.

3. The exhaust capacity is multiple times that of a regular dual orifice exhaust valve.

4. The floating ball bracket is made of stainless steel, with a long service life and safety and reliability.

Connection size

| Model |

Nominal Diameter |

Main size(mm) |

|||||||

|

D |

D1 |

D2 |

L |

Z-φd |

Medium |

阀体材料 |

|

||

|

QB2-10 |

40 |

145 |

110 |

85 |

430 |

4-φ18 |

Water |

Cast Iron |

|

|

QB2-10 |

50 |

160 |

125 |

100 |

430 |

4-φ18 |

Water |

Cast Iron |

|

|

QB2-10 |

75 |

195 |

160 |

135 |

470 |

4-φ18 |

Water |

Cast Iron |

|

|

QB2-10 |

100 |

215 |

180 |

155 |

500 |

4-φ18 |

Water |

Cast Iron |

|

|

QB2-10 |

150 |

280 |

240 |

210 |

540 |

8-φ20 |

Water |

Cast Iron |

|

|

QB2-10 |

200 |

335 |

295 |

265 |

700 |

8-φ20 |

Water |

Cast Iron |

|

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333