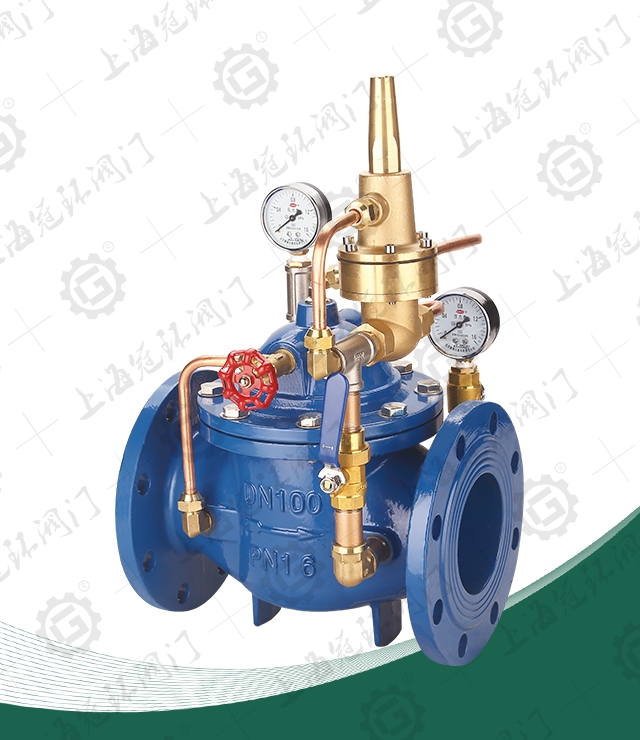

Single Opening Exhaust Valves

Nominal diameter: DN50~300mm

Nominal pressure: PN1.0~2.5MPa

Applicable temperature: 0 ° C~80 ° C

Applicable medium: clean water

The single port exhaust valve is used at the highest point on the pipeline or at the place with closed air, to exhaust the gas inside the pipeline to unblock it and achieve normal operation. If the exhaust valve is not installed, the liquid flowing in the pipeline will generate dynamic heat and cause gas, forming a short circuit, making it easy for the pipeline water to not meet the requirements. Secondly, if there is a power outage or pump shutdown during pipeline operation, negative pressure will occur in the pipeline, which can cause pipeline vibration or rupture. The (discharge) suction valve quickly sucks air into the pipeline to prevent pipeline vibration or rupture. There are two connection methods for single port exhaust valves, screw thread and flange.

A single port exhaust valve mainly consists of a valve body, valve, upper cover, valve stem, floating ball, exhaust nozzle, etc. When it is necessary to exhaust the gas in the pipeline, the air in the pipeline enters the body cavity under the pressure of water and is discharged from the exhaust nozzle. Subsequently, the water in the pipeline fills the body cavity, causing the floating ball to move upward under the buoyancy of water to block the exhaust nozzle and achieve self sealing. During normal operation of the pipeline, the air in the water is continuously discharged into the upper part of the exhaust valve cavity under the pressure, forcing the floating ball to descend and leave the original sealing position, At this point, the air is discharged from the exhaust nozzle again, and then the floating ball returns to its original position and self seals. Therefore, the exhaust valve is always open during normal operation, and the floating ball repeatedly repeats the above actions, continuously discharging the air. When it is necessary to repair or clean the body cavity, the valve should be closed. A single port exhaust valve is closed when the valve stem is rotated clockwise.

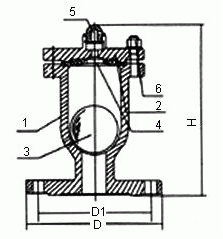

Connection size

|

Thread |

Specifications |

ZG |

Φ |

H |

Flange |

Specifications |

D |

D1 |

Φ |

H |

|

20 |

3/4" |

135 |

205 |

20 |

105 |

75 |

135 |

210 |

||

|

25 |

1" |

135 |

205 |

25 |

115 |

85 |

135 |

210 |

||

|

40 |

1 1/2" |

150 |

205 |

40 |

145 |

115 |

150 |

210 |

||

|

50 |

2" |

150 |

205 |

50 |

160 |

125 |

150 |

210 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333