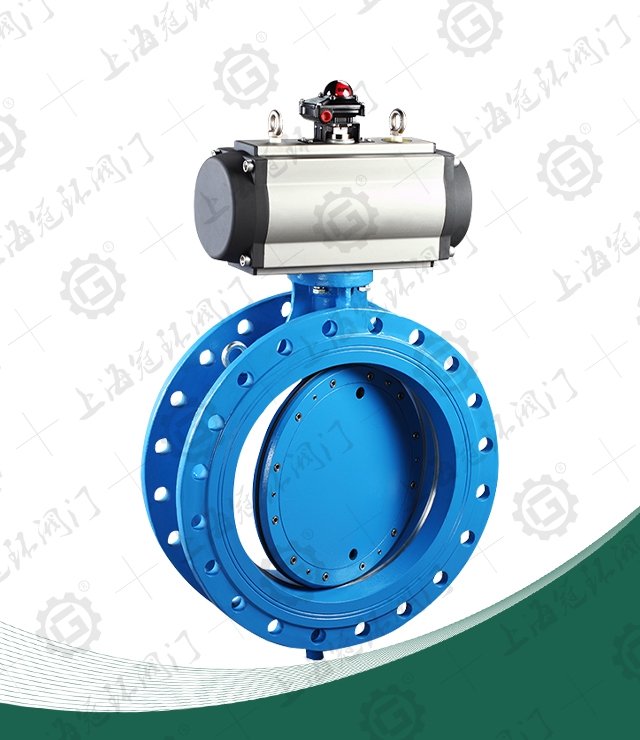

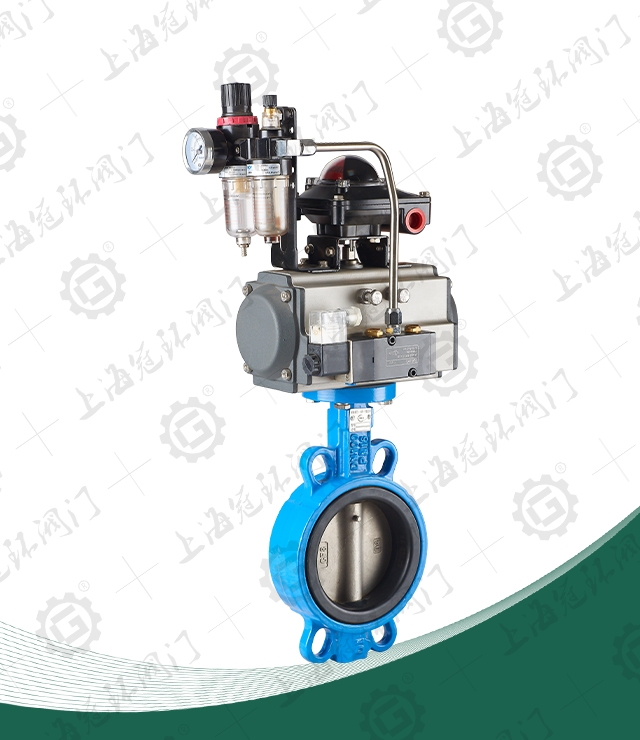

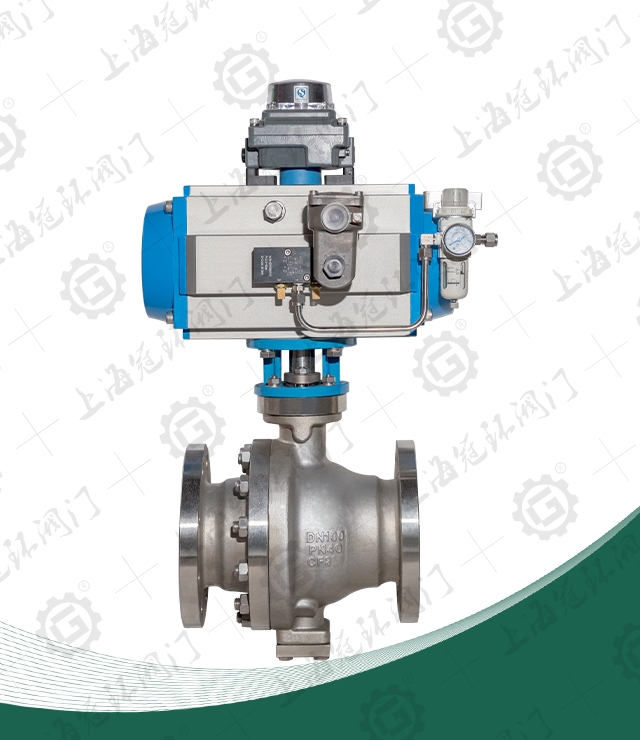

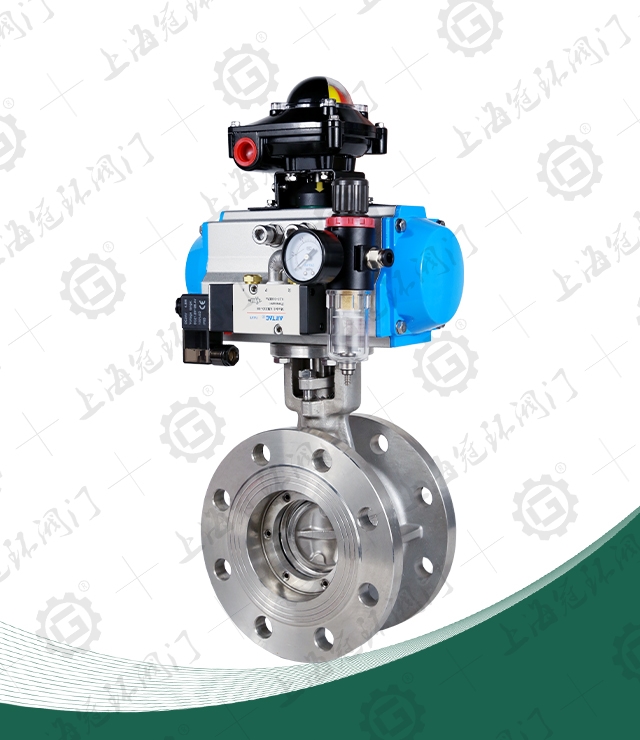

Pneumatic hard seal to clamp butterfly valve

Product overview

Pneumatic clamping butterfly valve with precision J-shaped elastic seal ring and three eccentric multi-layer metal hard seal structure, is widely used in the medium temperature ≤425℃ metallurgy, electric power, petrochemical industry and water supply and drainage and municipal construction and other industrial pipelines, for regulating flow and load body use. The valve adopts three eccentric structure, the valve seat and plate sealing surface are made of different hardness and stainless steel, with good corrosion resistance, long service life, the valve has a two-way sealing function.

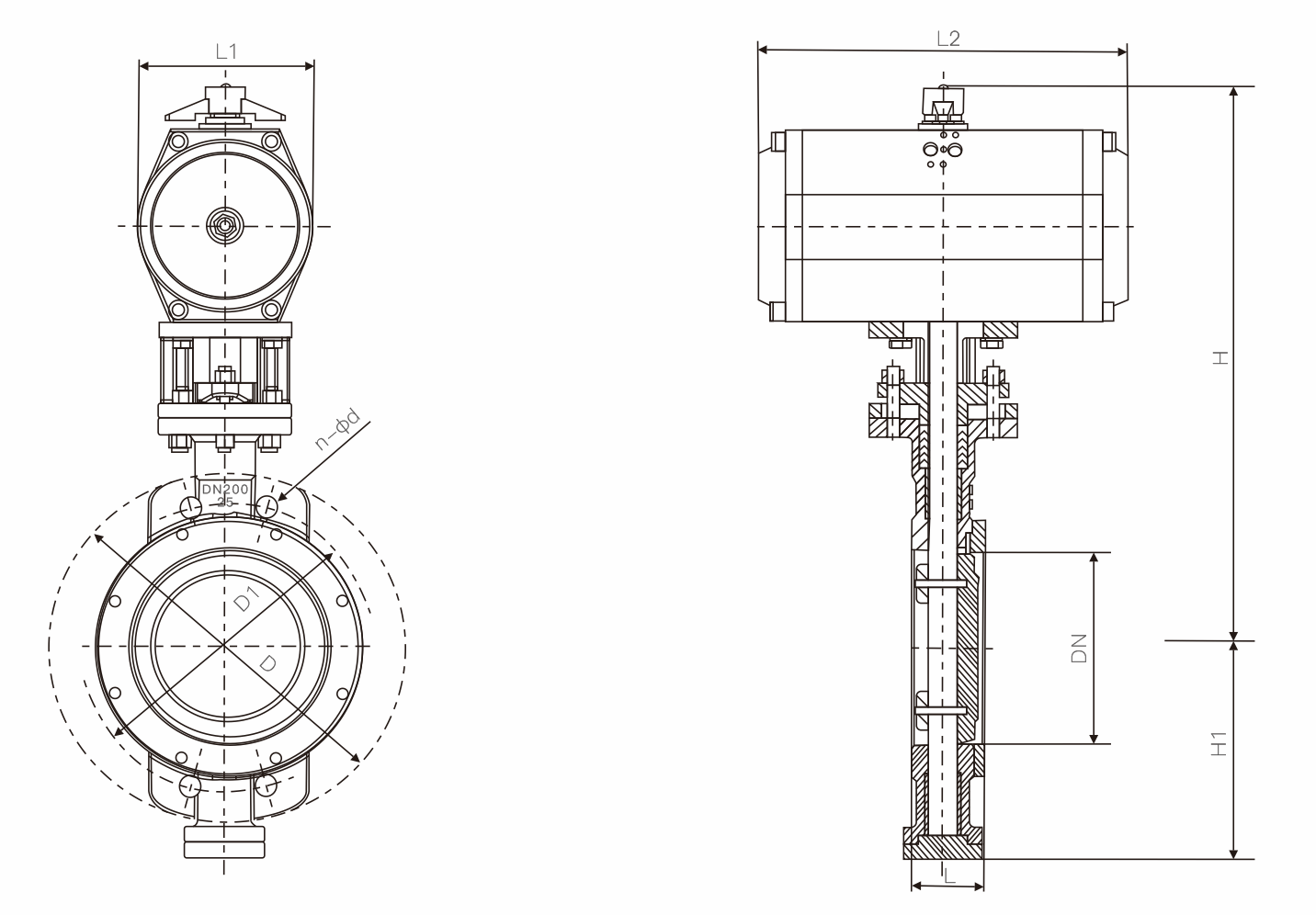

Main connection size

|

|

main dimension |

Flange dimensions and bolt specifications | |||||||

| 1.0MPa | 1.6MPa | 2.5MPa | |||||||

| L | H | H1 | D1 | 4-ФM | D1 | 4-ФM | D1 | 4-ФM | |

| 50 | 43 | 350 | 112 | 125 | Ф18 | 125 | Ф18 | 125 | Ф18 |

| 65 | 46 | 370 | 115 | 145 | Ф18 | 145 | Ф18 | 145 | Ф18 |

| 80 | 49 | 380 | 120 | 160 | Ф18 | 160 | Ф18 | 160 | Ф18 |

| 100 | 56 | 420 | 138 | 180 | Ф18 | 180 | Ф18 | 190 | Ф23 |

| 125 | 64 | 460 | 164 | 210 | Ф18 | 210 | Ф18 | 220 | Ф27 |

| 150 | 70 | 555 | 175 | 240 | Ф23 | 240 | Ф23 | 250 | Ф27 |

| 200 | 71 | 605 | 208 | 295 | M20 | 295 | M20 | 310 | M24 |

| 250 | 76 | 680 | 243 | 350 | M20 | 355 | M24 | 370 | M27 |

| 300 | 83 | 800 | 283 | 400 | M20 | 410 | M24 | 430 | M27 |

| 350 | 92 | 835 | 310 | 460 | M20 | 470 | M24 | 490 | M30 |

| 400 | 102 | 915 | 340 | 515 | M24 | 525 | M27 | 550 | M33 |

| 450 | 114 | 960 | 380 | 565 | M24 | 585 | M27 | 600 | M33 |

| 500 | 127 | 1020 | 410 | 620 | M24 | 650 | M30 | 660 | M33 |

| 600 | 154 | 1225 | 470 | 725 | M27 | 770 | M33 | 770 | M36 |

| 700 | 165 | 1355 | 550 | 840 | M27 | 840 | M33 | 875 | M39 |

| 800 | 190 | 1470 | 640 | 950 | M30 | 950 | M36 | 990 | M45 |

| 900 | 203 | 1545 | 710 | 1050 | M30 | 1050 | M36 | 1090 | M45 |

| 1000 | 216 | 1795 | 770 | 1160 | M33 | 1170 | M39 | 1210 | M52 |

| 1200 | 254 | 1965 | 890 | 1380 | M36 | 1390 | M45 | 1420 | M52 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333