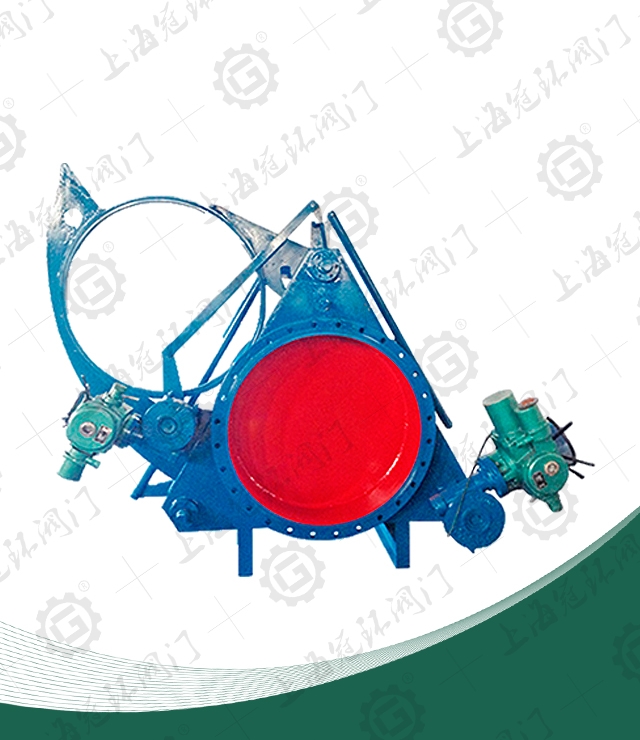

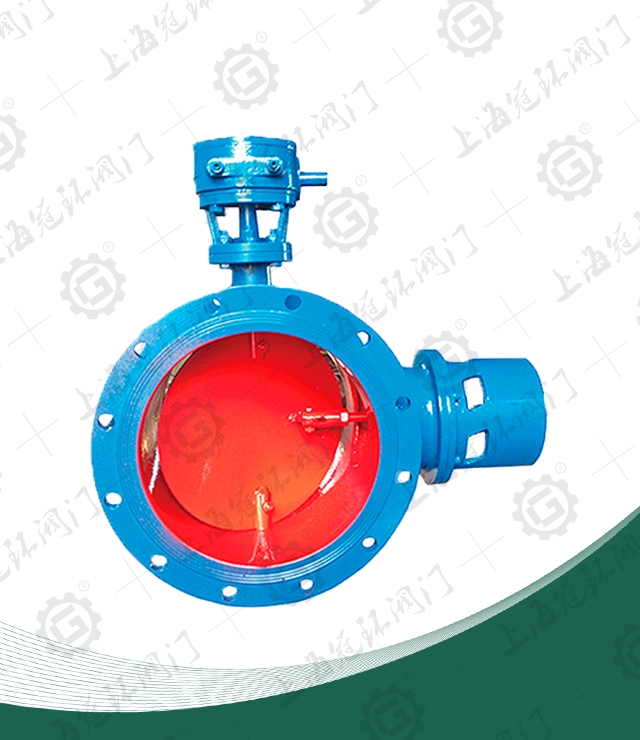

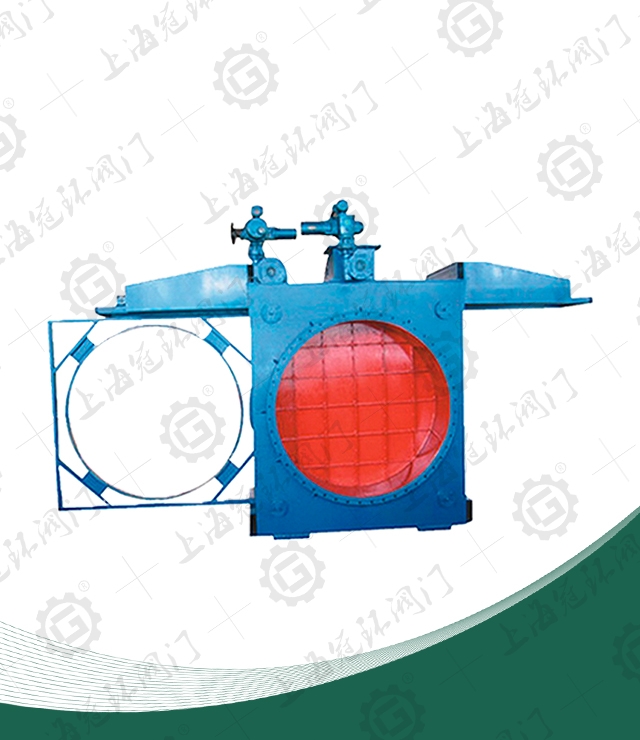

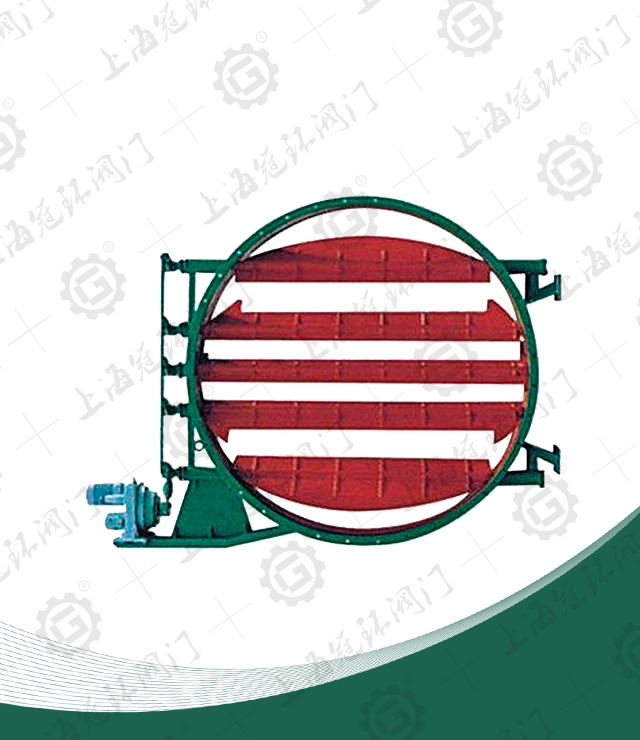

Hydraulic sector blind valve

Product overview

Main connection dimensions

| DN | L | D | D1 | A | H | H1 | b | n-Φd | weight(kg) | ||

| PN0.05 | PN0.15 | PN0.25 | |||||||||

| 300 | 450 | 440 | 395 | 480 | 720 | 360 | 22 | 12-22 | 205 | 225 | 250 |

| 350 | 450 | 490 | 445 | 520 | 810 | 380 | 22 | 12-22 | 235 | 255 | 280 |

| 400 | 450 | 540 | 495 | 600 | 920 | 400 | 22 | 16-22 | 250 | 275 | 300 |

| 450 | 500 | 595 | 550 | 658 | 995 | 427 | 24 | 16-22 | 300 | 330 | 360 |

| 500 | 500 | 645 | 600 | 712 | 1102 | 452 | 24 | 20-22 | 350 | 385 | 420 |

| 600 | 600 | 755 | 705 | 874 | 1600 | 650 | 26 | 20-26 | 420 | 460 | 500 |

| 700 | 600 | 860 | 810 | 970 | 1700 | 700 | 30 | 24-26 | 560 | 610 | 670 |

| 800 | 800 | 975 | 920 | 1100 | 1860 | 1125 | 30 | 24-30 | 1500 | 1650 | 1750 |

| 900 | 800 | 1075 | 1020 | 1200 | 2055 | 1270 | 32 | 24-30 | 1800 | 1950 | 2050 |

| 1000 | 800 | 1175 | 1120 | 1320 | 2240 | 1400 | 35 | 28-30 | 2100 | 2310 | 2500 |

| 1100 | 800 | 1275 | 1220 | 1510 | 2425 | 1535 | 35 | 28-30 | 2300 | 2500 | 2750 |

| 1200 | 800 | 1375 | 1320 | 1625 | 2621 | 1680 | 35 | 32-30 | 2600 | 2850 | 3200 |

| 1300 | 800 | 1475 | 1420 | 1749 | 2760 | 1770 | 35 | 32-33 | 3000 | 3300 | 3600 |

| 1400 | 850 | 1575 | 1520 | 1856 | 2960 | 1925 | 35 | 36-30 | 4170 | 4520 | 4900 |

| 1500 | 850 | 1690 | 1630 | 1976 | 3105 | 2050 | 35 | 36-30 | 4400 | 5150 | 5650 |

| 1600 | 850 | 1790 | 1730 | 1293 | 3300 | 2160 | 35 | 40-30 | 4750 | 5650 | 6150 |

| 1800 | 1100 | 1990 | 1930 | 2335 | 3610 | 2370 | 35 | 44-30 | 5750 | 7350 | 8050 |

| 2000 | 1100 | 2190 | 2130 | 2570 | 3960 | 2620 | 35 | 46-30 | 6750 | 9350 | 9800 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333