Orbital ball valve

Product model: GQ47H

Nominal diameter: DN15~900mm

Nominal pressure: PN1.6~2.5MPa

Working temperature: -190~550℃

Applicable medium: water, steam, oil

Main material: WCB

Structure length: JB/T7745 GB/T12221

Connecting flange: GB/T9113 JB/79 HG20592

Butt welding end: GB/T12224

Inspection and test: JB/T9092

The series orbital ball valve is a new type of pipeline valve developed

and designed by our company with the introduction of foreign advanced

technology. It is suitable for regulating, opening and closing pipeline

fluids in natural gas, oil, chemical, metallurgy and other industries.

Long-distance natural gas pipelines with hydrogen sulfide medium, many

impurities and severe corrosion.

Features

1. The static single seat structure ensures tight, reliable, and zero leakage bi-directional sealing.

2. Top mounted design allows for online maintenance of the system.

3. The cam mechanism at the lower end of the valve stem can provide a

mechanical wedge tightening force to ensure continuous tight sealing.

4. The opening and closing process is divided into two stages, with a short lifting stroke and easy operation.

5. During the opening and closing operation, the sealing surfaces are

completely out of contact, without wear, with high operating torque and

long service life.

6. The space formed between the ball and the

valve seat during the rotation process increases the flow rate of the

medium in the channel, thereby achieving the function of cleaning and

sealing.

7. The fire resistance design of ball valves follows the

provisions of standards such as API 607, API 6FA&JB/T 6899, etc. In

the event of a fire that causes the soft sealing ring to burn, the fire

resistant structure of the ball valve can prevent a large amount of

medium leakage and prevent further expansion of the fire.

8. Valve

driving devices include manual, worm gear and worm drive, and electric.

Electric valves are easy to achieve automatic control, easy to operate,

and safe and reliable.

Performance parameters

|

Model |

GQ47H-16C |

GQ47H-25C |

|

|

Work pressure(MPa) |

1.6 |

2.5 |

|

|

Operating temperature(℃) |

-190~550 |

||

|

Applicable medium |

water, steam, oil |

||

|

Material |

Body, bonnet |

WCB |

|

|

Stem |

2Cr13 |

||

|

Sphere |

WCB+HCr/STL |

||

|

Seat |

25 |

||

|

Filler |

Flexible graphite |

||

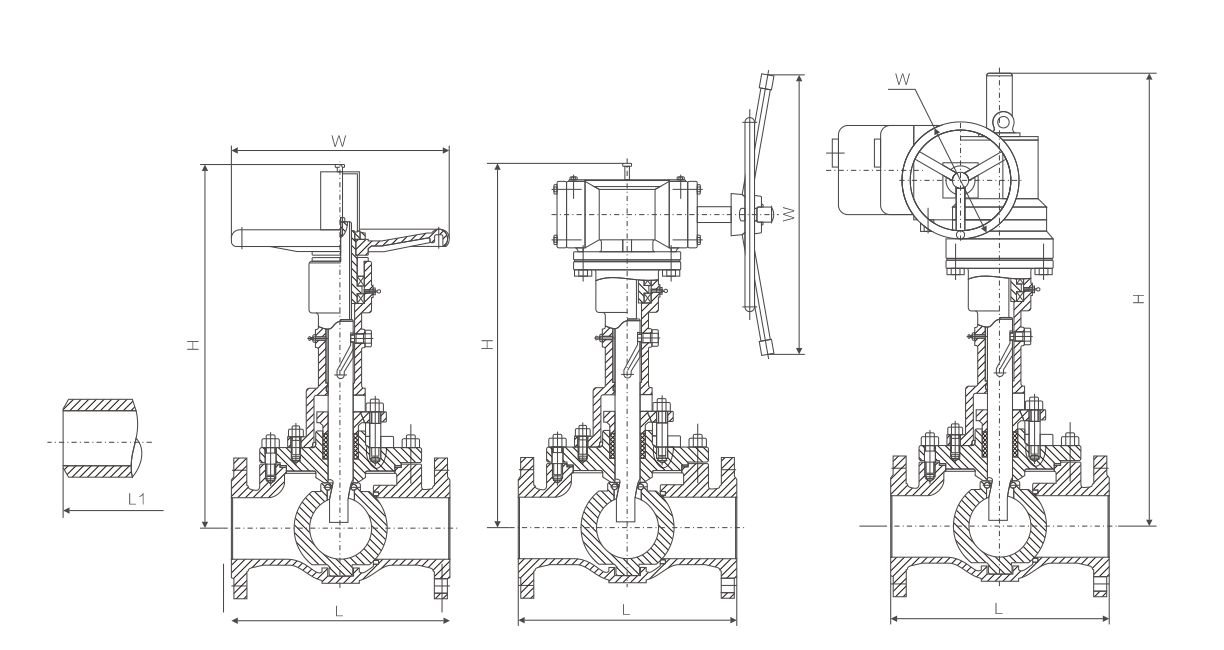

Main external connection dimensions

|

DN (mm) |

NPS (in) |

Class 150 |

PN1.6、2.5 |

Manual |

Gear |

Eectric |

||||||

|

L |

L1 |

L |

L1 |

H |

W |

WT (kg) |

H |

W |

H |

W |

||

|

15 |

1/2 |

108 |

- |

130 |

140 |

310 |

180 |

16 |

- |

- |

210 |

200 |

|

20 |

3/4 |

117 |

- |

150 |

152 |

325 |

180 |

8 |

- |

- |

225 |

200 |

|

25 |

1 |

127 |

- |

160 |

165 |

345 |

200 |

12 |

420 |

200 |

230 |

200 |

|

32 |

1 1/4 |

140 |

- |

180 |

178 |

360 |

200 |

16 |

440 |

200 |

290 |

500 |

|

40 |

1 1/2 |

165 |

190 |

200 |

190 |

380 |

200 |

19 |

455 |

200 |

300 |

500 |

|

50 |

2 |

178 |

216 |

230 |

216 |

385 |

200 |

28 |

465 |

200 |

570 |

460 |

|

65 |

2 1/2 |

190 |

241 |

290 |

241 |

393 |

300 |

43 |

480 |

200 |

625 |

460 |

|

80 |

3 |

203 |

283 |

310 |

283 |

402 |

300 |

58 |

500 |

300 |

760 |

460 |

|

100 |

4 |

229 |

305 |

350 |

305 |

510 |

300 |

75 |

510 |

300 |

780 |

460 |

|

150 |

6 |

394 |

457 |

480 |

457 |

690 |

400 |

133 |

680 |

300 |

850 |

460 |

|

200 |

8 |

457 |

521 |

600 |

521 |

785 |

500 |

225 |

820 |

400 |

840 |

460 |

|

250 |

10 |

533 |

559 |

730 |

559 |

995 |

600 |

345 |

910 |

400 |

960 |

460 |

|

300 |

12 |

610 |

635 |

850 |

635 |

1183 |

600 |

440 |

1090 |

400 |

990 |

460 |

|

350 |

14 |

686 |

762 |

980 |

762 |

1254 |

650 |

775 |

1330 |

600 |

1165 |

460 |

|

400 |

16 |

762 |

838 |

1100 |

838 |

1565 |

650 |

833 |

1380 |

600 |

1385 |

460 |

|

450 |

18 |

864 |

914 |

1200 |

914 |

1637 |

700 |

1110 |

1450 |

800 |

1415 |

460 |

|

500 |

20 |

914 |

991 |

1250 |

991 |

1705 |

700 |

1240 |

1840 |

800 |

1490 |

460 |

|

600 |

24 |

1067 |

1143 |

1450 |

1143 |

1883 |

800 |

1673 |

1870 |

800 |

1620 |

458 |

|

700 |

28 |

1346 |

1346 |

1346 |

1346 |

2108 |

800 |

2600 |

2130 |

800 |

1720 |

458 |

|

800 |

32 |

1524 |

1524 |

1524 |

1524 |

- |

- |

2820 |

- |

- |

- |

610 |

|

900 |

36 |

1727 |

1727 |

1727 |

2083 |

- |

- |

2950 |

- |

- |

- |

610 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333