Ultra low temperature fixed shut-off ball valve

Product model: DQ41F

Nominal diameter: DN15~500mm

Nominal pressure: PN1.6~10.0MPa

Applicable medium: water, oil, steam, acid and other corrosive media

Applicable temperature: -196-29℃

Main material: LCB, CF8

Drive mode: manual, electric, pneumatic

Design standard: ASMEB16.34GB/T12224

Structure length: ASMEB16.10GB/T12221

Connection flange: ASMEB16.34JB/T79

Test and check: JB/T9092 API 598

The ultra-low temperature fixed cut-off ball valve adopts a fixed ball structure. The ball core adopts full bore, with high rated flow coefficient and low flow resistance. The surface of the ball core is hardened using a special process to make it smooth and wear-resistant. The sealing material of the valve seat is polytetrafluorochloro Z-ene, which has low wear of the valve seat, excellent sealing, long service life, and extremely strong cutting performance. Widely used in low-temperature and cryogenic control such as metallurgy, oxygen production, petroleum, chemical engineering, etc.

Product Structure Features

1. Pressure parts of the material can withstand the temperature changes caused by the medium expansion, shrinkage, the structure of the sealing part of the temperature changes will not produce permanent deformation. For the following conditions -100 ℃, the valve parts should be cryogenic treatment before finishing, the parts will be immersed in a liquid nitrogen tank for cooling, when the temperature reaches -192 ℃ parts, start holding 1-2h, and then removed Natural treatment to the room temperature, review cycle 2 times.

2, the valve cover with long structure, its purpose to protect the function of stuffing box, the stuffing box at a farther position from the low temperature to ensure the sealing effect of packing, but also can be wound cold insulation material to prevent loss of cold energy. Long neck neck length according to the use of temperature and cold insulation material to choose a different length. When the packing sealing effect is reduced, you can add the grease from the middle of the packing box to form the oil seal layer, reducing the pressure difference of the packing box and improving the sealing performance.

3, the use of temperature below -100 ℃, the stem material after chrome or nitriding, improve the stem surface hardness and improve the reliability of packing seal.

4, the low temperature ball valve to prevent abnormal pressure structure, due to the low temperature valve gasification, the rapid expansion of its volume, the pressure will rise abnormally, when the valve cavity pressure rises, the valve cavity and import connectivity, or the valve inlet Pressure relief valve placed at the end to ensure the safe use of the valve.

5, low temperature ball valve gasket with at room temperature, low temperature conditions and temperature changes can be reliable sealing and recovery.

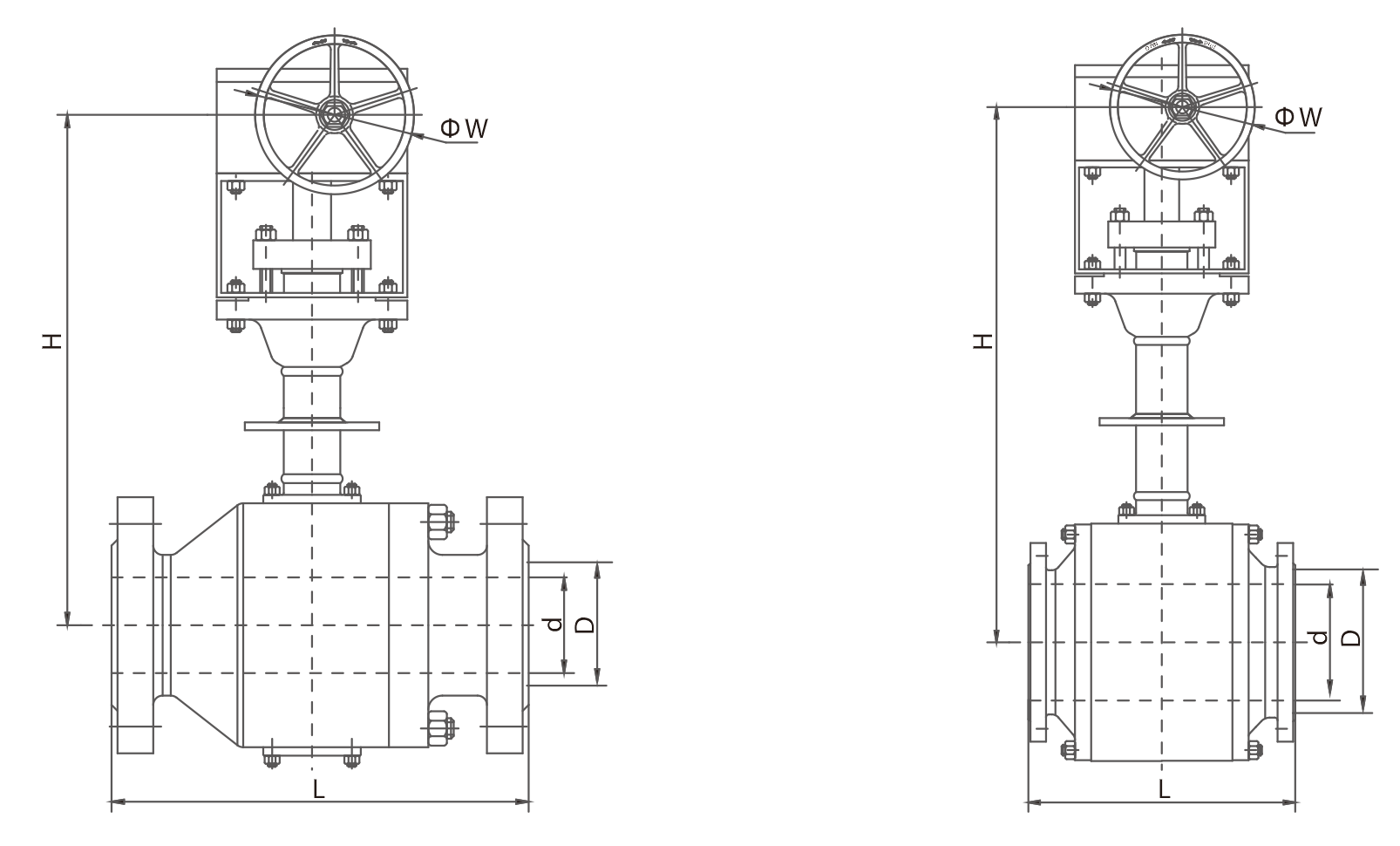

Product main dimensions

|

Product number |

Nominal diameter |

PN1.6-2.5MPa |

WT |

|||||||

|

DN |

L |

D |

D1 |

D2 |

b |

Z-Φd |

H |

W |

(kg) |

|

|

DQ41F-16C |

15 |

130 |

95 |

65 |

45 |

14 |

4-Φ14 |

178 |

140 |

3 |

|

20 |

140 |

105 |

75 |

55 |

14 |

4-Φ14 |

184 |

160 |

4 |

|

|

25 |

150 |

115 |

85 |

65 |

14 |

4-Φ14 |

195 |

180 |

5 |

|

|

DQ41F-16P |

32 |

165 |

135 |

100 |

78 |

16 |

4-Φ18 |

280 |

250 |

9 |

|

40 |

180 |

145 |

110 |

85 |

16 |

4-Φ18 |

280 |

300 |

11 |

|

|

50 |

203 |

160 |

125 |

100 |

16 |

4-Φ18 |

300 |

350 |

15 |

|

|

65 |

222 |

180 |

145 |

120 |

18 |

4-Φ18 |

330 |

350 |

19 |

|

|

80 |

241 |

195 |

160 |

135 |

20 |

8-Φ18 |

360 |

400 |

27 |

|

|

DQ9B41F-16C |

100 |

305 |

215 |

180 |

155 |

20 |

8-Φ18 |

400 |

500 |

38 |

|

125 |

356 |

245 |

210 |

185 |

22 |

8-Φ18 |

430 |

600 |

58 |

|

|

150 |

394 |

280 |

240 |

210 |

24 |

8-Φ23 |

500 |

800 |

81 |

|

|

200 |

457 |

335 |

295 |

265 |

26 |

12-Φ23 |

680 |

800 |

95 |

|

|

DQ9B41F-16P |

250 |

533 |

405 |

355 |

320 |

30 |

12-Φ25 |

790 |

1300 |

140 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333