Fluorine-lined control valve (pneumatic)

Nominal diameter: DN20~3500mm

Pressure range: PN1.6~6.4MPa

Operating temperature: -40~180 ℃ -20~+150 ℃

Manufacturing standard: GB/T4213-1992

Flange standard: GB/T9113-2000

Structure length: GB/T12221-2005

Gland type: bolt compression type

Internal packing: V-type polytetrafluoroethylene packing

Product overview

Pneumatic membrane lined

fluorine control valve is composed of pneumatic membrane actuator and

straight-through single-seat fluorine-lined valve. The parts in contact

with the medium of the fluorine-lined regulating valve are all

high-pressure injection molding process, lined with corrosion-resistant

and aging resistant polyperfluoroethylene propylene, and PTFE corrugated

pipe sealing to ensure no leakage. It is widely used in chemical,

petroleum, metallurgy, pharmaceutical, electric power and other

industries to control and regulate the process of acid, alkali strong

corrosive medium and toxic, volatile, permeable and other gaseous and

liquid media.

Structural features

1. The

corrosion-resistant valve cavity, valve core, valve seat and valve stem

are all 316 stainless steel, which can resist acid, alkali and strong

corrosion;

2. Good sealing performance, using polytetraethylene bellows and packing double seal to ensure no leakage;

3. The leakage amount is small because the valve core and valve seat

are soft seals, and the leakage amount is lower than the national IV

standard;

4. It adopts light and small multi-spring actuator, which is small in size, light in weight and high in adjustment accuracy;

5. The leakage amount is less than 0.01% of the rated capacity of the valve;

6. The differential belt positioner is less than 1% of the full stroke;

7. Basic error: with positioner: less than ±1% of the full stroke.

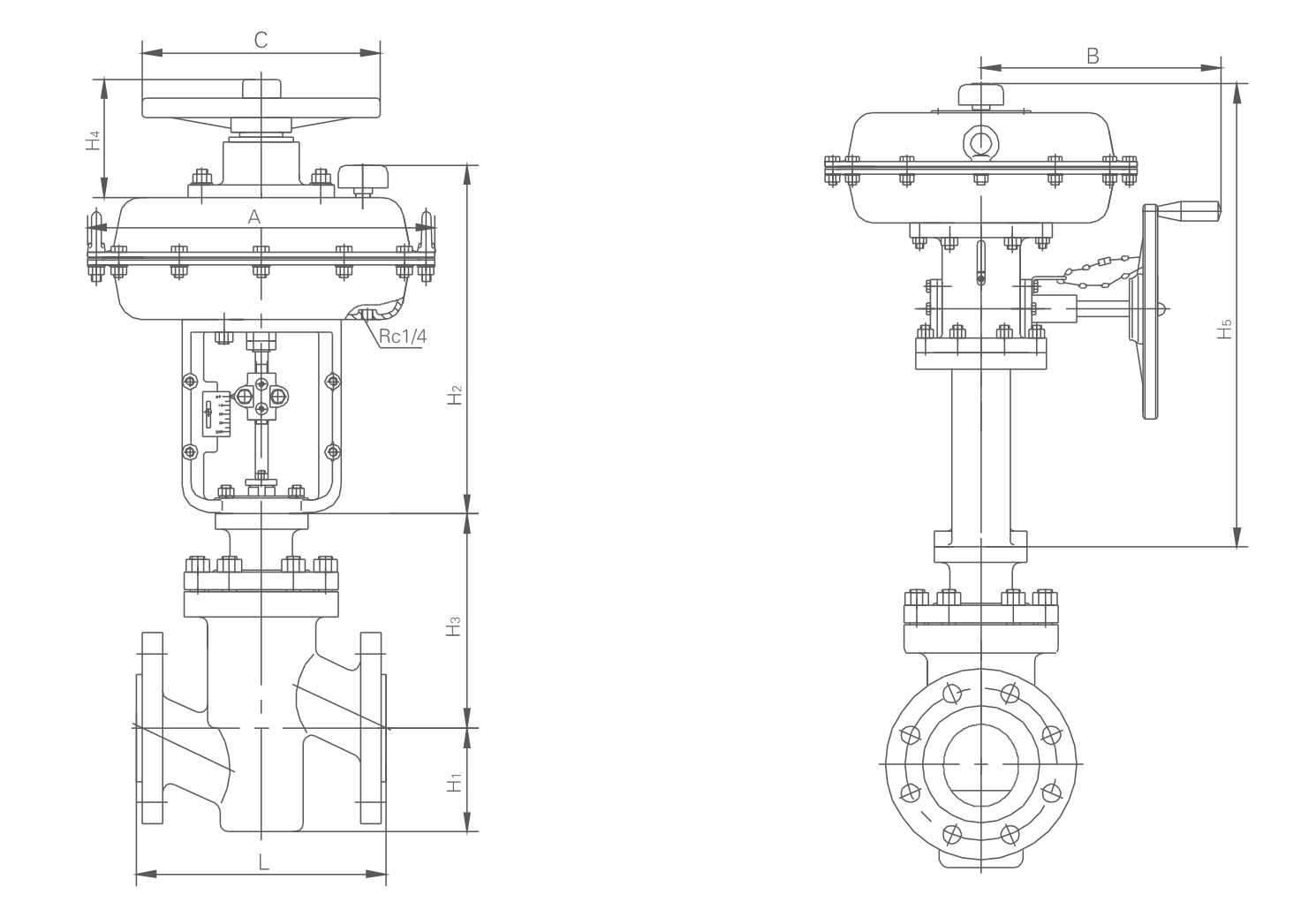

Main connect dimensions

|

DN(mm) |

L |

H1 |

H3 |

actuator |

|||||||

|

A |

C |

H2 |

H4 |

H5 |

B |

D |

H8 |

||||

|

20(3/4") |

180 |

155 |

65 |

232 |

220 |

255 |

180 |

- |

- |

225 |

370 |

|

282 |

220 |

258 |

180 |

305 |

260 |

225 |

370 |

||||

|

25(1") |

185 |

165 |

70 |

232 |

220 |

255 |

180 |

- |

- |

255 |

500 |

|

282 |

220 |

258 |

180 |

305 |

260 |

255 |

500 |

||||

|

32(1-1/4") |

200 |

165 |

80 |

282 |

220 |

258 |

180 |

305 |

260 |

255 |

500 |

|

308 |

220 |

280 |

180 |

305 |

260 |

255 |

500 |

||||

|

40(1-1/2") |

220 |

225 |

80 |

282 |

220 |

258 |

180 |

305 |

260 |

255 |

500 |

|

308 |

220 |

280 |

180 |

305 |

260 |

310 |

700 |

||||

|

50(2") |

250 |

225 |

88 |

308 |

220 |

280 |

180 |

305 |

260 |

310 |

700 |

|

65(2-1/2") |

275 |

300 |

102 |

308 |

220 |

280 |

180 |

305 |

260 |

310 |

700 |

|

394 |

270 |

360 |

236 |

580 |

305 |

310 |

700 |

||||

|

80(3") |

300 |

300 |

140 |

308 |

220 |

280 |

180 |

305 |

260 |

310 |

700 |

|

394 |

270 |

360 |

236 |

580 |

305 |

310 |

700 |

||||

|

100(4") |

350 |

300 |

170 |

394 |

270 |

360 |

236 |

580 |

305 |

310 |

700 |

|

125(5") |

400 |

400 |

250 |

394 |

270 |

360 |

236 |

580 |

305 |

310 |

750 |

|

498 |

320 |

435 |

310 |

675 |

330 |

310 |

750 |

||||

|

150(6") |

486 |

400 |

260 |

394 |

270 |

360 |

236 |

580 |

305 |

310 |

750 |

|

498 |

320 |

435 |

310 |

675 |

330 |

- |

- |

||||

|

200(8") |

600 |

405 |

290 |

498 |

320 |

435 |

310 |

675 |

330 |

- |

- |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333