Plug valve

Pressure range: Class150~600Lb

Working temperature: -29~180 ℃

Main material: WCB, WC6, WC9, C5, C12, CF8, CF8M, CF3, CF3M, CN7M, LCB, LCC

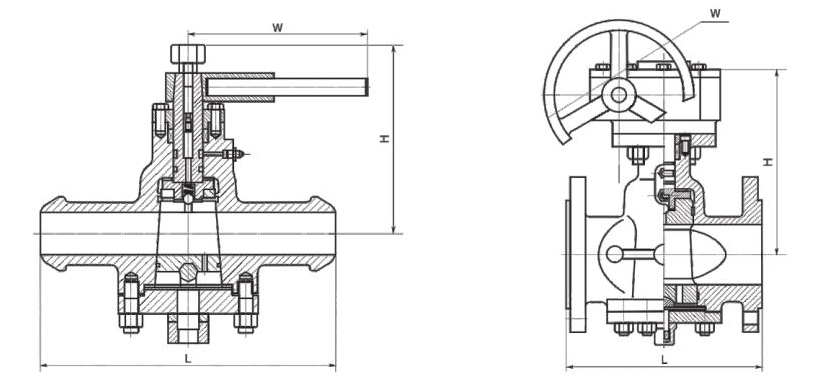

Drive mode: manual, worm gear

Plug valves are suitable for cutting or connecting pipeline media in various operating conditions such as petroleum, chemical, pharmaceutical, fertilizer, and power industries with a nominal pressure of Class150-CLASS600 and a working temperature of -29-180 ℃. There is an oil groove between the valve body and sealing surface of the plug valve, which can inject sealing grease into the valve seat at any time through the oil nozzle, increasing sealing performance. The material and flange size of the plug valve parts can be reasonably selected according to actual working conditions or user requirements to meet various engineering needs.

Structural characteristics

1. The product has a reasonable structure, reliable sealing, excellent performance, and beautiful appearance;

2. Inverted pressure balanced structure with light switching action;

3. There is an oil groove between the valve body and the sealing surface, which can inject sealing grease into the valve seat at any time through the oil nozzle to increase sealing performance;

4. The material and flange size of the parts can be reasonably selected according to actual working conditions or user requirements to meet various engineering needs.

Product size

| model | ZDAX47-150LB | |||||||||||||||

| pressure rating | 150LB | |||||||||||||||

| caliber | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| Size | in | 1 | 1¼ | 1½ | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | ||

| L | 108 | 117 | 127 | 140 | 165 | 178 | 190 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 | |

| H | 180 | 180 | 185 | 200 | 210 | 215 | 250 | 270 | 300 | 340 | 365 | 400 | 450 | 510 | 590 | |

| W | 400 | 400 | 500 | 500 | 600 | 600 | 820 | 820 | 300 | 300 | 320 | 320 | 350 | 380 | 380 | |

| WT(Kg) | 10 | 12 | 14 | 17 | 19 | 21 | 29 | 33 | 48 | 75 | 98 | 125 | 171 | 230 | 370 | |

| model | ZDAX47-300LB | |||||||||||||||

| pressure rating | 300LB | |||||||||||||||

| caliber | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| Size | in | 1 | 1¼ | 1½ | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | ||

| L | 140 | 152 | 165 | 178 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 762 | |

| H | 180 | 180 | 185 | 200 | 210 | 215 | 250 | 270 | 300 | 340 | 365 | 400 | 450 | 510 | 590 | |

| W | 400 | 400 | 500 | 600 | 600 | 820 | 1000 | 1000 | 300 | 300 | 320 | 320 | 350 | 380 | 380 | |

| WT(Kg) | 12 | 14 | 16 | 19 | 21 | 24 | 31 | 36 | 61 | 86 | 130 | 190 | 255 | 380 | 560 | |

| ZDAX47-600LB | ||||||||||||||||

| pressure rating | 600LB | |||||||||||||||

| caliber | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| Size | In | 1/2 | 3/4 | 1 | 1¼ | 1½ | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 |

| L | 165 | 190 | 216 | 229 | 241 | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | |

| H | 180 | 180 | 185 | 200 | 210 | 215 | 250 | 270 | 300 | 340 | 365 | 400 | 450 | 510 | 590 | |

| W | 400 | 400 | 500 | 500 | 600 | 600 | 820 | 820 | 300 | 300 | 320 | 320 | 350 | 380 | 380 | |

| WT(Kg) | 14 | 16 | 18 | 20 | 24 | 29 | 35 | 47 | 91 | 129 | 210 | 320 | 660 | 920 | 1250 | |

| ZDAX47-900LB | ||||||||||||||||

| pressure rating | 900LB | |||||||||||||||

| caliber | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| Size | in | 1/2 | 3/4 | 1 | 1¼ | 1½ | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 |

| L | 229 | 229 | 254 | 279 | 305 | 368 | 419 | 381 | 457 | 559 | 610 | 737 | 838 | 965 | 1029 | |

| H | 180 | 180 | 185 | 200 | 210 | 215 | 250 | 270 | 300 | 340 | 365 | 400 | 450 | 510 | 590 | |

| W | 400 | 400 | 500 | 600 | 600 | 820 | 1000 | 1000 | 300 | 300 | 320 | 320 | 350 | 380 | 380 | |

| WT(Kg) | 17 | 29 | 21 | 24 | 30 | 37 | 44 | 65 | 110 | 160 | 255 | 380 | 810 | 1050 | 1460 | |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333