API standard lifting plug valve

Nominal diameter: DN15-350mm 1/2 "-14"

Nominal pressure: CL150-1500LB

Applicable temperature: -29~550 ℃

Applicable media: water, steam, oil, etc

Sealing structure: soft seal, hard seal

Structural form: lifting type

Connection type: flange

Main materials: brass, cast iron, cast steel, stainless steel

The American standard lifting plug valve is suitable for cutting or connecting pipeline media in various working conditions such as petroleum, chemical, pharmaceutical, fertilizer, and power industries with a nominal pressure of Class150-1500LB and a working temperature of -29~550 ℃.

Structural characteristics

1. The product structure is reasonable, with reliable sealing, excellent performance, and beautiful appearance.

2. The opening and closing process of the valve is carried out when the sealing surface is detached, and it will not cause wear on the sealing surface.

3. Bidirectional flow makes installation and use more convenient.

4. The material and flange size of the parts can be reasonably selected according to actual working conditions or user requirements to meet various engineering needs.

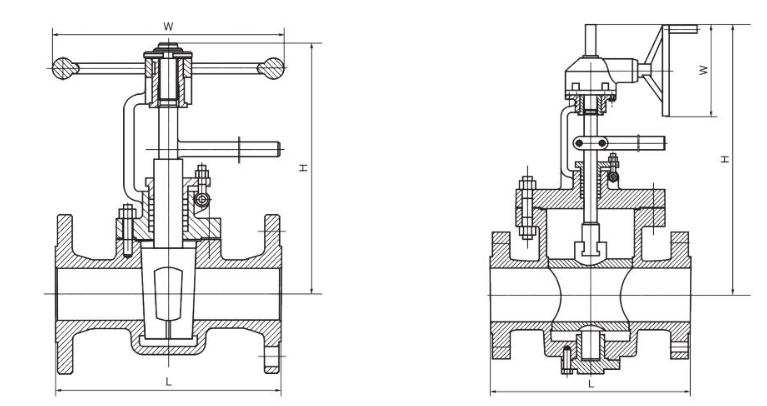

Main outer connect dimensions

| Model | ALX43H/X-150LB | |||||||||||||||

| pressure rating | 150LB | |||||||||||||||

| caliber | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| Size | in | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 |

| L | 108 | 117 | 127 | 140 | 165 | 178 | 190 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 | |

| H | 190 | 195 | 225 | 260 | 280 | 310 | 340 | 395 | 435 | 470 | 535 | 590 | 630 | 680 | 720 | |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 | |

| Weight(Kg) | 9 | 10 | 11 | 17 | 19 | 23 | 25 | 32 | 55 | 82 | 98 | 130 | 178 | 250 | 380 | |

| Model | ALX43H/X-300LB | |||||||||||||||

| pressure rating | 300LB | |||||||||||||||

| caliber | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| Size | in | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 |

| L | 140 | 152 | 165 | 178 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 762 | |

| H | 190 | 195 | 225 | 260 | 280 | 310 | 340 | 395 | 435 | 470 | 535 | 590 | 630 | 680 | 720 | |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 | |

| Weight(Kg) | 10 | 12 | 14 | 19 | 21 | 28 | 34 | 39 | 75 | 95 | 135 | 200 | 255 | 415 | 650 | |

| Model | ALX43H/X-600LB | |||||||||||||||

| pressure rating | 600LB | |||||||||||||||

| caliber | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| Size | in | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 |

| L | 165 | 190 | 216 | 229 | 241 | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | |

| H | 190 | 195 | 225 | 260 | 280 | 310 | 340 | 395 | 435 | 470 | 535 | 590 | 630 | 680 | 720 | |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 | |

| Weight(Kg) | 13 | 14 | 19 | 23 | 25 | 32 | 40 | 55 | 105 | 139 | 300 | 440 | 730 | 1150 | 1570 | |

| Model | AXL43H/X-900LB | |||||||||||||||

| pressure rating | 900LB | |||||||||||||||

| caliber | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| Size | in | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 |

| L | 229 | 229 | 254 | 279 | 305 | 368 | 419 | 381 | 457 | 559 | 610 | 737 | 838 | 965 | 1029 | |

| H | 190 | 195 | 225 | 260 | 280 | 310 | 340 | 395 | 435 | 470 | 535 | 590 | 630 | 680 | 720 | |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 | |

| Weight(Kg) | 16 | 17 | 26 | 30 | 33 | 39 | 50 | 70 | 137 | 181 | 397 | 590 | 860 | 1470 | 1880 | |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333