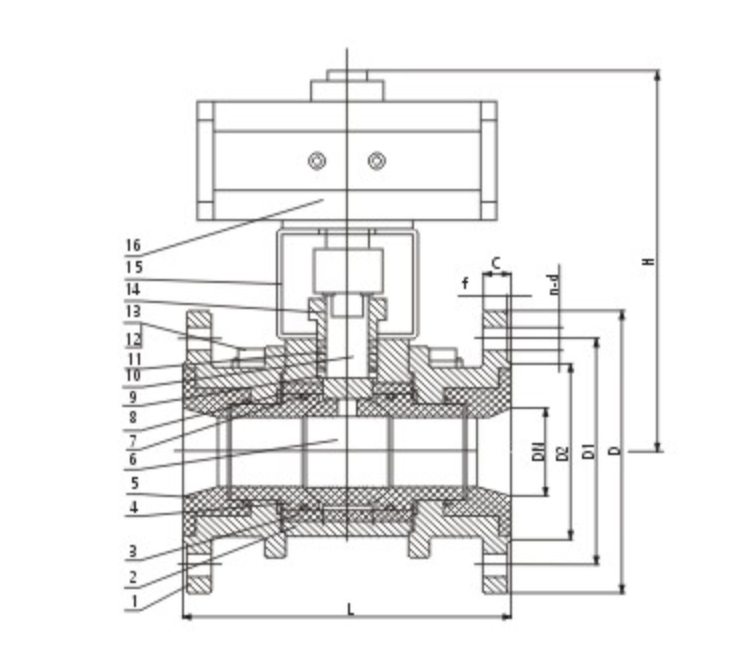

Pneumatic ceramic ball valve

|

L | D | K | D1 | n-Φd | b | f | H | W | |

| mm | in | |||||||||

| 15 | 1/2″ | 130 | 95 | 65 | 46 | 4-Φ14 | 14 | 2 | 190 | 196 |

| 20 | 3/4″ | 140 | 105 | 75 | 56 | 4-Φ14 | 16 | 2 | 195 | 196 |

| 25 | 1″ | 150 | 115 | 85 | 64 | 4-Φ14 | 16 | 2 | 210 | 196 |

| 32 | 1 1/4″ | 165 | 135 | 100 | 76 | 4-Φ18 | 18 | 3 | 220 | 196 |

| 40 | 1 1/2″ | 180 | 145 | 110 | 84 | 4-Φ18 | 18 | 3 | 230 | 196 |

| 50 | 2″ | 200 | 160 | 125 | 99 | 4-Φ18 | 20 | 3 | 265 | 196 |

| 65 | 2 1/2″ | 220 | 180 | 145 | 118 | 4-Φ18 | 22 | 3 | 300 | 255 |

| 80 | 3″ | 250 | 195 | 160 | 132 | 8-Φ18 | 24 | 3 |

325 |

255 |

|

100 |

4″ |

280 |

235 |

190 |

156 |

8-Φ22 |

24 |

3 |

350 |

255 |

|

125 |

5″ |

320 |

270 |

220 |

184 |

8-Φ26 |

26 |

3 |

375 |

255 |

|

150 |

6″ |

360 |

300 |

250 |

211 |

8-Φ26 |

28 |

3 |

420 |

255 |

|

200 |

8″ |

400 |

360 |

310 |

274 |

12-Φ26 |

30 |

3 |

460 |

255 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333