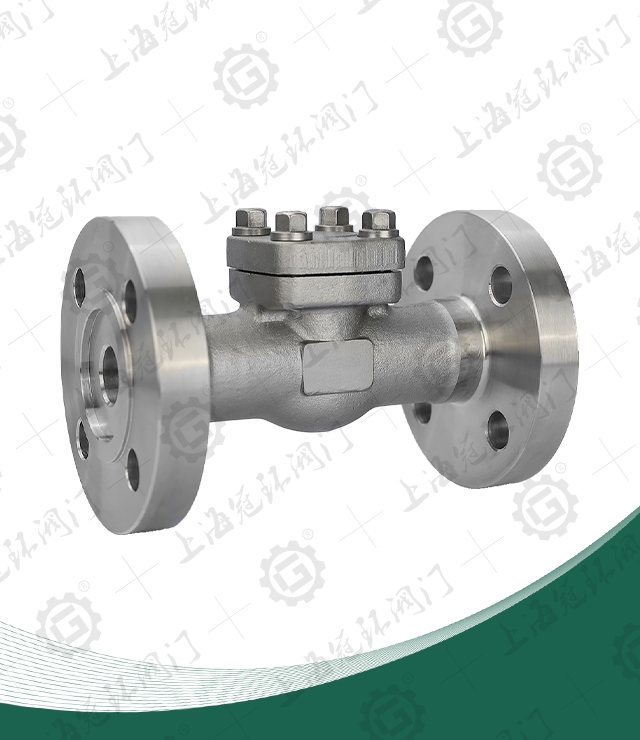

CNS Forged Steel Flange Globe Valve

Nominal diameter: DN15 ~ 50mm

Pressure range: PN1.6~10.0MPa

Operating temperature: -29℃ ~ 550℃

Main material: carbon steel, stainless steel, alloy steel

Applicable medium: water, steam, oil, nitric acid, acetic acid, etc

Application scope: suitable for tap water, food, pharmaceutical, electric power, petroleum, liquefied gas, steam, and other media pipeline

J41Y GB Forged Steel Flange Globe Valve produced and sold by Baigang valve group Integral Flange Valve There are three kinds of bonnet design, the first is the bolt-type bonnet, connected by concave and convex surface, with stainless steel band and flexible graphite spiral wound gasket, can also be used on demand Ring connection, the second is a welded bonnet, welded by thread sealing, can also be used directly on demand rigid welding, the third is self-sealing bonnet, threaded and self-sealing bonnet connection. Products are widely used in petroleum, chemical, pharmaceutical, power industry and other conditions of the pipeline.

Features and Benefits

1.The

product is designed and manufactured strictly according to API602, BS

5352 standards. The valve disc is positioned along the center for

lifting movement (the bushing is made of special material with good

abrasion resistance and small friction coefficient) Flexible and

reliable, excellent sealing performance. Products are widely used in

petroleum, chemical, pharmaceutical, power industry and other conditions

of the pipeline.

2.Handwheel forged with malleable iron, with the

shape of the hand grip, an appropriate increase in friction, easy to

open. And showed obvious "open" and "off" mark. Larger caliber, higher

pressure optional impact handwheel.

3.Stem nut with high nickel

ductile iron, "T" thread and stem with the transfer torque. Valve cover

gland packing and pressure split design, to ensure the concentricity of

the stem. Reasonable stuffing box to ensure that no leakage valve. Meet

the environmental requirements.

4.bonnet with seal seat. Meets API requirements of the American Petroleum Institute and British BS standards.

Main overall connection dimensions

| PN (MPa) | DN (mm) | 15 | 20 | 25 | 32 | 40 | 50 | 65 |

| 1.6 | d | 10 | 13 | 19.1 | 24 | 31.8 | 38.1 | 48.5 |

| 2.5 | ||||||||

| 4.0 | ||||||||

| 6.4 | ||||||||

| 10.0 | ||||||||

| 1.6 | L | 130 | 150 | 160 | 190 | 200 | 230 | 290 |

| 2.5 | ||||||||

| 4.0 | ||||||||

| 6.4 | 170 | 190 | 210 | 230 | 260 |

300 |

340 | |

| 10.0 | ||||||||

| 1.6 | H | 158 | 163 | 193 | 250 | 250 | 291 | 350 |

| 2.5 | ||||||||

| 4.0 | ||||||||

| 6.4 | ||||||||

| 10.0 | ||||||||

| 1.6 | W | 100 | 100 | 125 | 160 | 160 | 180 | 240 |

| 2.5 | ||||||||

| 4.0 | ||||||||

| 6.4 | ||||||||

| 10.0 | ||||||||

| 1.6 | WT (kg) | 3.8 | 4.5 | 5.6 | 6.3 | 9.1 | 13.7 | 24.5 |

| 2.5 | 4.0 | 4.7 | 5.8 | 6.5 | 10.7 | 15.3 | 26.2 | |

| 4.0 | 4.3 | 5.0 | 6.3 | 7.0 | 12.3 | 18.8 | 27.7 | |

| 6.4 | 4.8 | 5.6 | 8.0 | 9.4 | 13.7 | 23.7 | 32.0 | |

| 10.0 | 5.4 | 6.6 | 9.8 |

10.5 |

18.6 | 27.6 | 35.0 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333