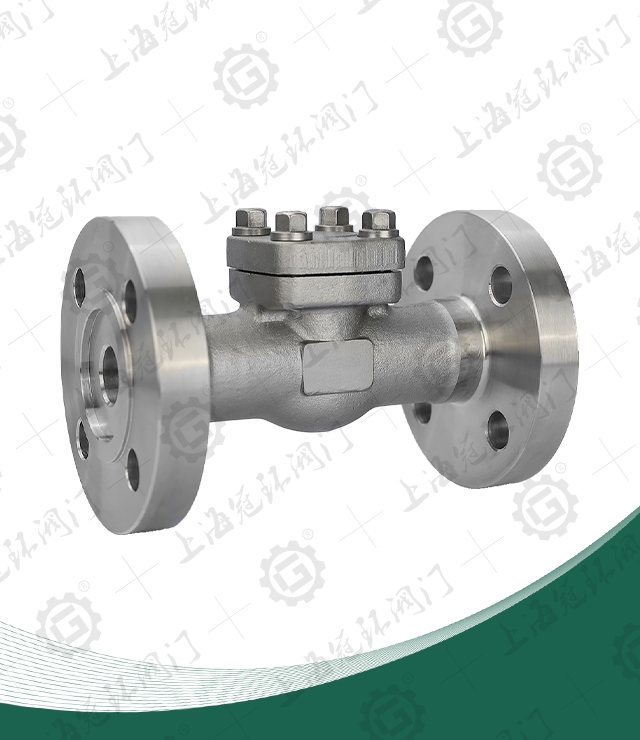

Forged Steel Socket Welding Check Valve

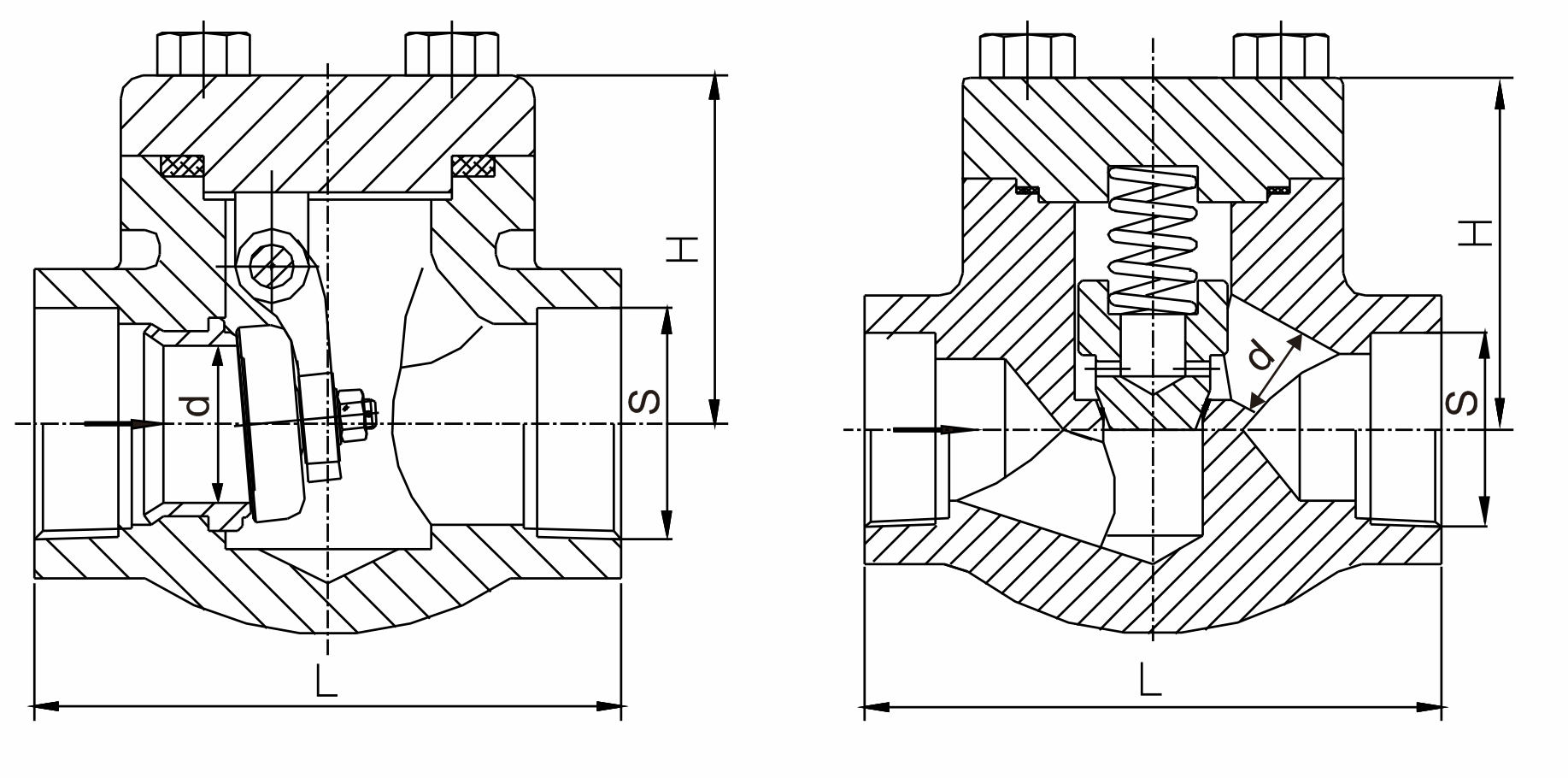

Product model: H11Y/H61Y

Nominal diameter: DN15-50mm, NPS 1/2"-2"

Pressure range: CL150-600Lb

Body material: forged steel, stainless steel

Applicable temperature: -29℃~550℃

Applicable medium: water, steam, oil, etc.

Forged steel internal thread, the sealing surface of the socket check valve is made of iron-based alloy or Stellite cobalt-based cemented carbide surfacing surface for wear resistance, high temperature resistance, corrosion resistance, good scratch resistance, long service life, etc. Features. The connection between the stainless steel pin shaft and the valve disc adopts the built-in structure, which has excellent performance and more reliable sealing. The products are widely used in the pipelines of petroleum, chemical, pharmaceutical, electric power industries and other working conditions to prevent medium backflow. Applicable media are water, oil, steam, gas and some corrosive liquid media.

Product Features

1. The valve is an automatic sealing valve, which automatically opens and closes the valve flap depending on the flow of the medium itself, effectively preventing the backflow of the medium. The disc has a stainless steel spring device. The sealing surface is wear-resistant, corrosion-resistant, friction-resistant and has a long service life. The product has reasonable structure, reliable sealing, excellent performance and beautiful appearance.

2. The shape of the valve body is the same as that of the globe valve, so its fluid resistance coefficient is large. The upper part of the valve disc and the lower part of the valve cover are machined with guide sleeves. When the medium flows downstream, the valve disc is opened by the thrust of the medium. When the medium stops flowing, the valve disc falls on the valve seat by itself, which prevents the medium from flowing backwards.

Main external connection dimensions and weight(Clss150LB~600LB)

| NPS(in) | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" | ||

| L(RTJ) | 150 | 108 | 117 | 127 | 140 | 165 | 203 | |

| 300 | 152 | 178 | 203 | 216 | 229 | 267 | ||

| 600 | 165 | 190 | 216 | 229 | 241 | 292 | ||

| H | 150,300 | 61 | 61 | 79 | 95 | 103 | 118 | |

| 600 | 61 | 79 | 95 | 103 | 118 | 135 | ||

|

WT (Kg) |

150 | RTJ | 2.56 | 3.37 | 4.37 | 8.17 | 8.94 | 12.64 |

| BW | 1.7 | 1.9 | 2.1 | 5.12 | 5.5 | 7.89 | ||

| 300 | RTJ | 2.73 | 3.65 | 4.74 | 8.77 | 9.6 | 13.7 | |

| BW | 1.9 | 2.1 | 3 | 5.12 | 6.6 | 7.85 | ||

| 600 | RTJ | 3 | 4 | 5.83 | 9.47 | 10.1 | 15.6 | |

| BW | 2 | 3.12 | 4.25 | 7.25 | 8.56 | 13.6 | ||

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333