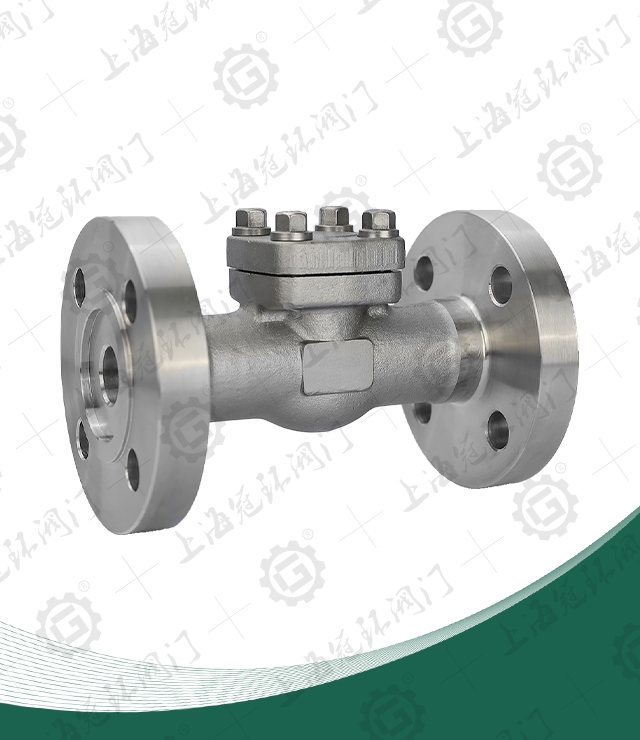

Stainless steel forged steel check valve

Product model: H41Y

Nominal diameter: NPS1/2 "~2"

Nominal pressure: Class150~600Lb

Working temperature: 600 ℃

Applicable media: water, oil, steam, gases, certain corrosive liquids, etc

Main materials: A105N, A182 F22, A182 F304 (L), A182 F316 (L)

Structure length: according to ANSI B16.5 F16.5

The American standard forged steel flange check valve disc and seat

sealing surface are made of cobalt based hard alloy plasma spray

welding, which has high hardness, erosion resistance, and durability.

Suitable for cutting or connecting media on pipelines under various

operating conditions such as petroleum, chemical, hydraulic, and thermal

power plants with a working temperature of 600 ℃. Applicable media

include water, oil, steam, gases, and certain corrosive liquids.

Operational Principle

The forged steel flange check valve disc and seat sealing surface are

made of iron based alloy or Stellite cobalt based hard alloy surfacing,

which is characterized by wear resistance, high temperature resistance,

corrosion resistance, good scratch resistance, and long service life.

The connection between the stainless steel pin shaft and the valve disc

adopts an internal structure with excellent performance and more

reliable sealing. The product is widely used in various working

conditions such as petroleum, chemical, pharmaceutical, and power

industries to prevent medium backflow in pipelines. Applicable media

include water, oil, steam, gas, and certain corrosive liquid media.

Standard Material List

Product Features

1. The guide rib is welded with hard alloy, and the guide sleeve of the upper chamber of the valve body is made of stainless steel material to ensure flexible valve disc movement.

2. The sealing surface of the valve disc and valve seat is made of cobalt based hard alloy plasma spray welding, which has high hardness, erosion resistance, and durability.

3. Pressure seal design and high-purity graphite gasket ring to ensure high air tightness.

4. The inner chamber of the valve adopts a pressure self tightening sealing structure, and the higher the inner chamber pressure, the better the sealing performance.

5. The valve disc rotates around the pin axis outside the valve seat, reducing the violent impact that occurs during closure.

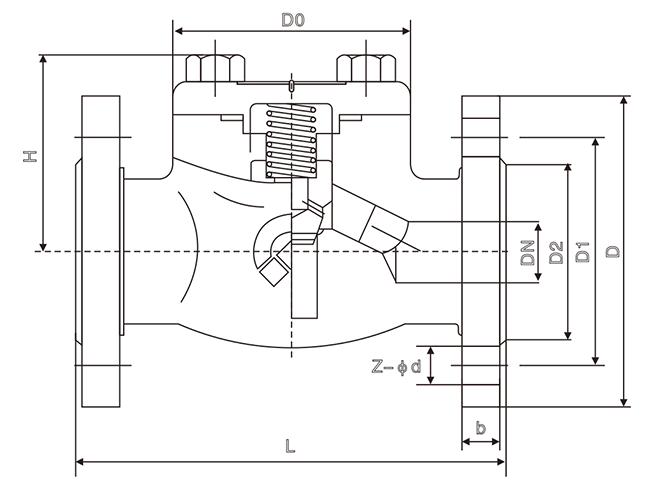

Main connection dimensions and weight

|

NPS |

1/2 |

3/4 |

1 |

11/4 |

11/2 |

2 |

||

|

L(RTJ) |

150 |

108 |

117 |

127 |

140 |

165 |

203 |

|

|

300 |

152 |

178 |

203 |

216 |

229 |

267 |

||

|

600 |

165 |

190 |

216 |

229 |

241 |

292 |

||

|

H |

150,300 |

61 |

61 |

79 |

95 |

103 |

118 |

|

|

600 |

61 |

79 |

95 |

103 |

118 |

135 |

||

|

Weight |

150 |

RTJ |

2.56 |

3.37 |

4.37 |

8.17 |

8.94 |

12.64 |

|

BW |

1.70 |

1.90 |

2.10 |

5.12 |

5.50 |

7.89 |

||

|

300 |

RTJ |

2.73 |

3.65 |

4.74 |

8.77 |

9.60 |

13.70 |

|

|

BW |

1.90 |

2.10 |

3.00 |

5.12 |

6.60 |

7.85 |

||

|

600 |

RTJ |

3.00 |

4.00 |

5.83 |

9.47 |

10.10 |

15.6 |

|

|

BW |

2.00 |

3.12 |

4.25 |

7.25 |

8.56 |

13.60 |

||

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333