Plunger stop valve

Nominal diameter: DN15-300mm

Nominal pressure: PN1.6~10.0MPa

Applicable temperature: ≤ 425 ℃

Applicable media: water, steam, oil, corrosive media, etc

operational principle

Product Features

1. When opening and closing the plunger valve, the plunger moves slowly in the sealing ring, and the contact surface is almost not worn.2. The sealing ring adopts a non-toxic new sealing material with strong elasticity and high wear resistance, so the sealing is reliable and durable.

3. An interference fit is used between the plunger and sealing ring in the valve to ensure the sealing of the valve and prevent internal and external leakage.

4. When closed, the plunger is inserted into the lower sealing ring to cut off the flow passage; When opened, although the plunger detaches from the lower sealing ring, it is still hidden inside the upper sealing ring to maintain isolation from the outside and prevent leakage.

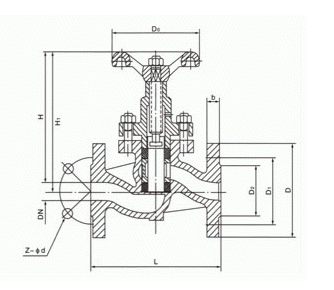

Main outer dimensions

|

1.6MPa U41SM-16Z U41SM-16C U41SM-16P/R |

||||||||||||||||||

|

Nominal Diameter DN(mm) |

15 |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

350 |

|

||

|

Main outer dimensions and connect dimensions |

L |

130 |

150 |

160 |

180 |

200 |

230 |

290 |

310 |

350 |

400 |

480 |

600 |

650 |

698 |

787 |

|

|

|

D |

95 |

105 |

115 |

135 |

145 |

160 |

180 |

195 |

215 |

245 |

280 |

335 |

405 |

460 |

520 |

|

|

|

|

D1 |

65 |

75 |

85 |

100 |

110 |

125 |

145 |

160 |

180 |

210 |

240 |

295 |

355 |

410 |

470 |

|

|

|

|

D2 |

45 |

55 |

65 |

78 |

85 |

100 |

120 |

135 |

155 |

185 |

210 |

265 |

320 |

375 |

435 |

|

|

|

|

b |

14 |

14 |

14 |

16 |

16 |

16 |

18 |

20 |

20 |

22 |

24 |

26 |

30 |

30 |

34 |

|

|

|

|

Z-φd |

4-φ14 |

4-φ14 |

4-φ14 |

4-φ18 |

4-φ18 |

4-φ18 |

8-φ18 |

8-φ18 |

8-φ18 |

8-φ18 |

8-φ23 |

12-φ23 |

12-φ25 |

12-φ25 |

16-φ25 |

|

|

|

|

H |

133 |

140 |

165 |

180 |

200 |

226 |

267 |

300 |

340 |

388 |

410 |

498 |

580 |

985 |

110 |

|

|

|

|

Weight |

kg |

3.6 |

4.5 |

6 |

8.8 |

12 |

16 |

22 |

30 |

42 |

62 |

88 |

155 |

240 |

330 |

540 |

|

|

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333