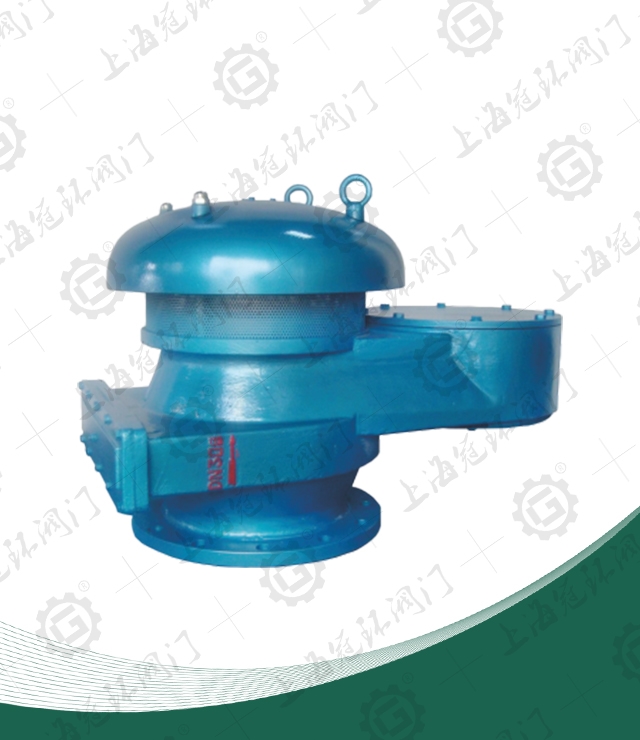

All-weather breathing valve

Nominal diameter: DN50~300mm

Nominal pressure: PN0.6~1.6MPa

Working temperature: 30-60 ℃

Applicable media: kerosene, diesel, toluene, etc

The new all-weather breathing valve is suitable for storing Class A oil products with a flash point D of 28 ℃ and Class B oil products with a flash point D of 60 ℃, such as gasoline, benzene, methyl benzene, kerosene, light diesel, engine oil, crude oil, and chemical product storage tanks with the same properties. It can be used together with the new corrugated flame arrester.

Instructions

The breathing valve is installed on the top of the storage tank to

solve the problem of positive and negative pressure gas inside the tank,

so that the liquid inside the tank is not obstructed. When the external

liquid enters the tank, a large amount of gas is exhaled (called

positive pressure). When the liquid inside the tank is output to the

outside, it must be sucked into the tank from the outside air (called

negative pressure). If the breathing valve automatically closes when it

stops working, it will not cause the liquid and gas in the tank to leak

out, providing a favorable guarantee for the quality of the liquid in

the tank.

Maintenance and upkeep

For the

safety of using the breathing valve, check whether the guide rod and

valve disc are flexible before use. This valve should be regularly

(within 6 months) checked for flexibility of the positive and negative

valve discs at the ventilation port, and for any damage to the contact

surface of the valve disc. If there is any damage, it should be repaired

immediately. After maintenance, everything is normal and can be reused.

National standard flange connection external dimensions: GB, JB

|

model |

Installation dimensions(mm) |

||||

|

d1 |

d |

d3 |

h |

m-h |

|

| dn25 | 70 | 100 | 115 | 180 | 4×10 |

|

dn50 |

110 |

140 |

160 |

255 |

4×12 |

|

dn80 |

150 |

185 |

213 |

260 |

4×16 |

|

dn100 |

170 |

205 |

265 |

290 |

4×16 |

|

dn150 |

225 |

260 |

305 |

330 |

8×16 |

|

dn200 |

280 |

315 |

355 |

350 |

8×16 |

|

dn250 |

335 |

370 |

420 |

400 |

12×16 |

American standard flange connection external dimensions: Ansi, API, and ASME can be provided as JIS standards

|

model |

Installation dimensions(mm) |

||||

|

d1 |

d |

d3 |

h |

m-h |

|

| 1" | 79.5 | 108 | 115 | 180 | 4×15 |

|

2" |

120.5 |

152 |

160 |

255 |

4×19 |

|

3" |

152.5 |

190 |

213 |

260 |

4×19 |

|

4" |

190.5 |

229 |

265 |

290 |

8×19 |

|

6" |

241.5 |

254 |

305 |

330 |

8×22 |

|

8" |

298.5 |

343 |

355 |

350 |

8×22 |

|

10" |

362 |

406 |

420 |

400 |

12×25 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333