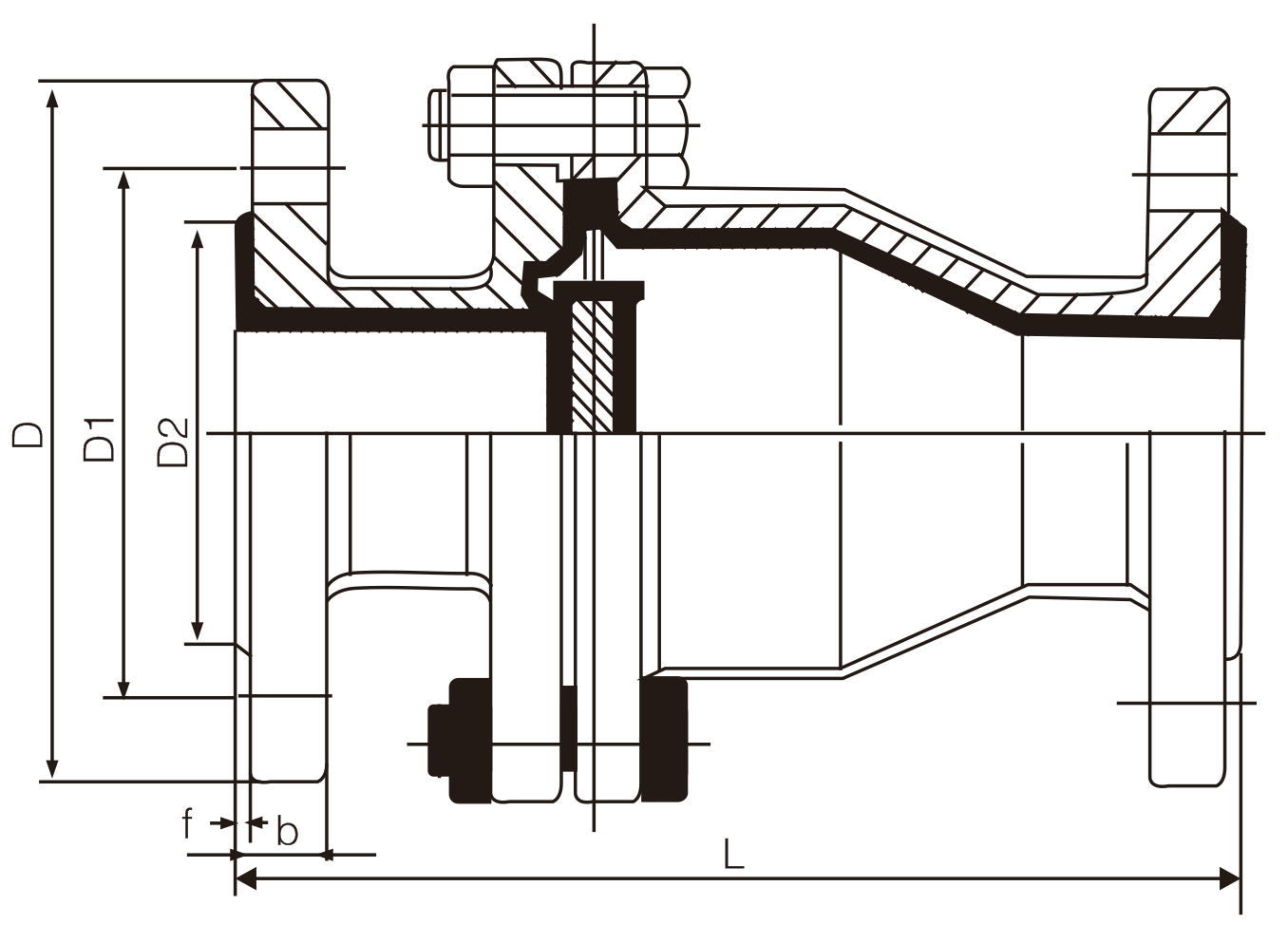

Swing check valves H44J

Nominal diameter: DN15~500 (mm)

Nominal pressure: PN1.0~1.6 (MPa)

Connection method: flange

Applicable temperature: ≤ 85 ℃, ≤ 100 ℃, ≤ 120 ℃ (according to lining material)

Valve body material: ductile iron, cast steel, stainless steel

Design and manufacturing: GB12236 Structure length: GB12221 Flange connection: GB4216

The H44J swing rubber lined check valve is specifically designed for non corrosive or general corrosive media. The surface of the valve body cavity is free of dirt or covered with various types of adhesive options, suitable for different working temperatures and wave body pipelines. H44) The swing check valve is an automatic valve that mainly functions to prevent backflow of the previous material, reverse rotation of the pump and driving motor, and discharge of the container material. The upper check valve can also be used to provide supply to the auxiliary system in which the Le Li may rise above the system pressure.

| Nominal Diameter |

Standard value |

Reference value |

||||||

|

DN (mm) |

NPS (in) |

L

|

H |

W(Kg) |

||||

|

H44 |

H41 |

HQ40 |

0.6Mpa |

1.0Mpa |

1.6Mpa |

|||

|

0.6~1.6Mpa |

||||||||

|

15 |

1/2 |

130 |

108 |

55 |

4 |

5 |

6 |

|

|

20 |

3/4 |

150 |

117 |

58 |

5 |

7 |

7.8 |

|

|

25 |

1 |

160 |

127 |

60 |

6 |

9 |

10 |

|

|

32 |

1 1/4 |

180 |

140 |

75 |

7 |

11 |

12.5 |

|

|

40 |

1 1/2 |

200 |

165 |

82 |

8 |

13.5 |

14.5 |

|

|

50 |

2 |

230 |

178 |

95 |

10 |

18 |

19.5 |

|

|

65 |

2 1/2 |

290 |

190 |

105 |

20 |

22 |

25.5 |

|

|

80 |

3 |

310 |

203 |

120 |

25 |

28 |

30 |

|

|

100 |

4 |

350 |

229 |

135 |

30 |

34 |

36 |

|

|

125 |

5 |

400 |

254 |

158 |

50 |

58 |

62 |

|

|

150 |

6 |

480 |

394 |

180 |

65 |

72 |

78 |

|

|

200 |

8 |

495 |

600 |

457 |

215 |

137 |

150 |

156 |

|

250 |

10 |

622 |

533 |

240 |

150 |

165 |

172 |

|

|

300 |

12 |

698 |

755 |

- |

265 |

185 |

190 |

240 |

|

350 |

14 |

787 |

850 |

- |

300 |

215 |

225 |

235 |

|

400 |

16 |

914 |

- |

350 |

244 |

254 |

265 |

|

|

450 |

18 |

978 |

- |

- |

- |

276 |

285 |

- |

|

500 |

20 |

978 |

- |

- |

- |

315 |

333 |

- |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333