American standard stop valve

Product structure characteristics

Main structural features

1, product design and manufacture according to ASME B16.34 and BS 1873 standards, reasonable structure, reliable sealing, excellent performance, beautiful appearance.

2, sealing surface surfacing Co based cemented carbide, wear resistance, corrosion resistance, abrasion resistance, long service life.

3, the valve stem after tempering and surface nitriding treatment, has good corrosion resistance and abrasion resistance.

4, the pressure ≥Class1500 cavity adopts a self-tightening sealing structure, the tightness increases with the internal pressure, to ensure the reliability of the seal.

5, the valve is equipped with reverse sealing structure, sealing reliable.

6, the material of the parts and the size of the flange butt welding end can be reasonably selected according to the actual working conditions or user requirements to meet various engineering needs.

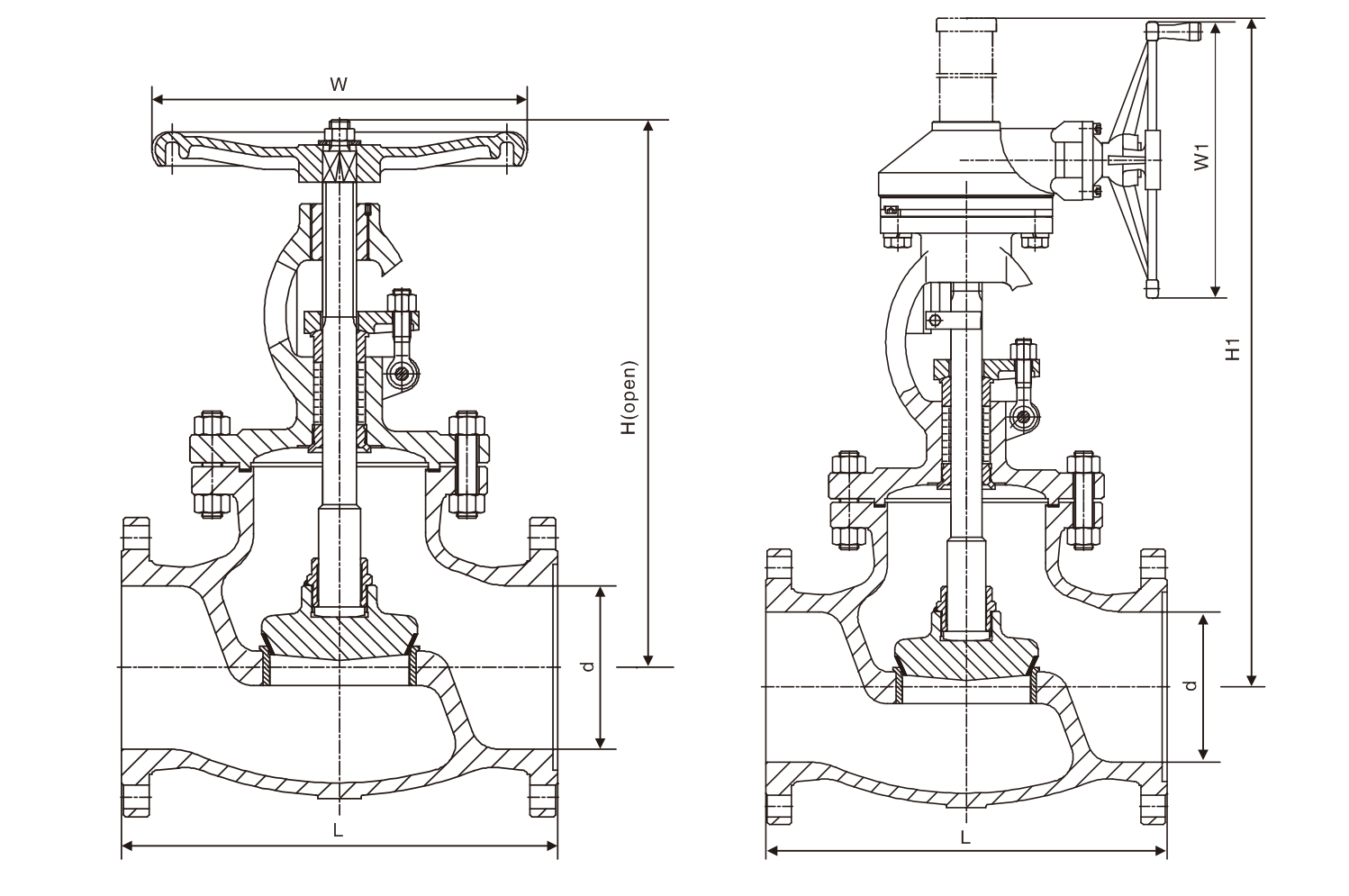

Main shape connection size and weight

|

150Lb Raised-face flange(RF) Main size(mm) |

Weight (Kg) |

||||||||

| mm | in | L | D | D1 | D2 | b | n-φd | H | D0 | |

| 15 | 1/2 | 108 | 89 | 60.5 | 35 | 11.2 | 4-16 | 241 | 100 | 6.9 |

| 20 | 3/4 | 117 | 98 | 69.9 | 43 | 12.7 | 4-16 | 241 | 100 | 9.8 |

| 25 | 1 | 127 | 108 | 79.2 | 51 | 14.2 | 4-16 | 242 | 125 | 13.5 |

| 32 | 1-1/4 | 140 | 117 | 89 | 63 | 16 | 4-16 | 280 | 160 | 19.5 |

| 40 | 1-1/2 | 165 | 127 | 98.6 | 73 | 17.5 | 4-16 | 286 | 160 | 28.5 |

| 50 | 2 | 203 | 152 | 120.7 | 92 | 19 | 4-19 | 368 | 200 | 18 |

| 65 | 2-1/2 | 216 | 178 | 139.7 | 105 | 22.4 | 4-19 | 387 | 200 | 30 |

| 80 | 3 | 241 | 190 | 152.4 | 127 | 24 | 4-19 | 411 | 250 | 41 |

| 100 | 4 | 292 | 229 | 190.5 | 157 | 24 | 4-19 | 454 | 250 | 64 |

| 125 | 5 | 356 | 254 | 216.0 | 186 | 24 | 8-22.5 | 455 | 350 | 86 |

| 150 | 6 | 406 | 279 | 241.3 | 216 | 25.4 | 8-22.5 | 541 | 350 | 113 |

| 200 | 8 | 495 | 343 | 298.5 | 270 | 28.4 | 8-22.5 | 651 | 450 | 178 |

| 250 | 10 | 622 | 406 | 362.0 | 324 | 30.2 | 12-25.4 | 800 | 450 | 270 |

| 300 | 12 | 698 | 483 | 431.8 | 381 | 32 | 12-25.4 | 1231 | 600 | 350 |

| 350 | 14 | 787 | 533 | 476.3 | 413 | 35 | 12-29 | 1450 | 600 | 460 |

| 400 | 16 | 914 | 597 | 539.8 | 470 | 36.6 | 26-29 | 1645 | 600 | 590 |

|

300Lb Raised-face flange(RF) Main size(mm) |

Weight (Kg) |

||||||||

| 15 | 1/2 | 152 | 95 | 66.5 | 35 | 14.2 | 4-16 | 241 | 140 | 7.7 |

| 20 | 3/4 | 178 | 117 | 82.5 | 43 | 16 | 4-19 | 241 | 140 | 11.3 |

| 25 | 1 | 203 | 123 | 89 | 51 | 17.5 | 4-19 | 283 | 160 | 16.8 |

| 32 | 1-1/4 | 216 | 133 | 98.5 | 63 | 19 | 4-19 | 320 | 200 | 21.2 |

| 40 | 1-1/2 | 229 | 155 | 114.3 | 73 | 20.6 | 4-22.5 | 322 | 200 | 32.6 |

| 50 | 2 | 267 | 165 | 127 | 92 | 22.4 | 8-19 | 399 | 200 | 25 |

| 65 | 2-1/2 | 292 | 190 | 149.4 | 105 | 25.4 | 8-22.5 | 438 | 250 | 30 |

| 80 | 3 | 318 | 210 | 168.1 | 127 | 28.4 | 8-22.5 | 464 | 280 | 35 |

| 100 | 4 | 356 | 254 | 200.2 | 157 | 31.8 | 8-22.5 | 565 | 350 | 56 |

| 125 | 5 | 400 | 279 | 235 | 186 | 35 | 8-22.5 | 614 | 350 | 96 |

| 150 | 6 | 444 | 318 | 269.7 | 216 | 36.6 | 12-25.4 | 717 | 400 | 120 |

| 200 | 8 | 559 | 381 | 330.2 | 270 | 41.2 | 12-25.4 | 930 | 500 | 212 |

| 250 | 10 | 622 | 444 | 387.4 | 324 | 47.8 | 16-28.5 | 1012 | 550 | 330 |

| 300 | 12 | 711 | 521 | 450.8 | 381 | 50.8 | 16-32 | 1231 | 600 | 472 |

| 350 | 14 | 762 | 584 | 514.4 | 413 | 54 | 20-32 | 1450 | 600 | 715 |

| 400 | 16 | 864 | 648 | 571.5 | 470 | 57.2 | 20-35 | 1645 | 600 | 920 |

|

600Lb Raised-face flange(RF) Main size(mm) |

Weight (Kg)

|

||||||||

| mm | in | L | D | D1 | D2 | b | n-φd | H | D0 | |

| 15 | 1/2 | 165 | 95 | 66.5 | 35 | 14.5 | 4-16 | 285 | 100 | 7.8 |

| 20 | 3/4 | 190 | 117 | 82.5 | 43 | 16 | 4-19 | 285 | 125 | 12.5 |

| 25 | 1 | 216 | 124 | 89 | 51 | 17.5 | 4-19 | 313 | 160 | 17.5 |

| 32 | 1-1/4 | 229 | 133 | 98.5 | 63 | 21 | 4-19 | 328 | 160 | 23.5 |

| 40 | 1-1/2 | 241 | 156 | 114.3 | 73 | 22.5 | 4-22.5 | 365 | 180 | 38.5 |

| 50 | 2 | 292 | 165 | 127 | 92 | 33 | 8-19 | 444 | 200 | 35 |

| 65 | 2-1/2 | 330 | 190 | 149.4 | 105 | 36 | 8-22.5 | 483 | 250 | 50 |

| 80 | 3 | 356 | 210 | 168.1 | 127 | 39 | 8-22.5 | 533 | 250 | 60 |

| 100 | 4 | 432 | 273 | 216 | 157 | 45 | 8-25.4 | 622 | 350 | 110 |

| 125 | 5 | 508 | 330 | 266.7 | 186 | 52 | 8-28.5 | 750 | 350 | 200 |

| 150 | 6 | 559 | 356 | 292.1 | 216 | 55 | 12-28.5 | 800 | 450 | 230 |

| 200 | 8 | 660 | 419 | 349.3 | 270 | 63 | 12-32 | 927 | 500 | 410 |

| 250 | 10 | 787 | 508 | 431.8 | 324 | 71 | 16-35 | 1257 | 600 | 625 |

| 300 | 12 | 838 | 559 | 489 | 381 | 74 | 20-35 | 1468 | 680 | 860 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333