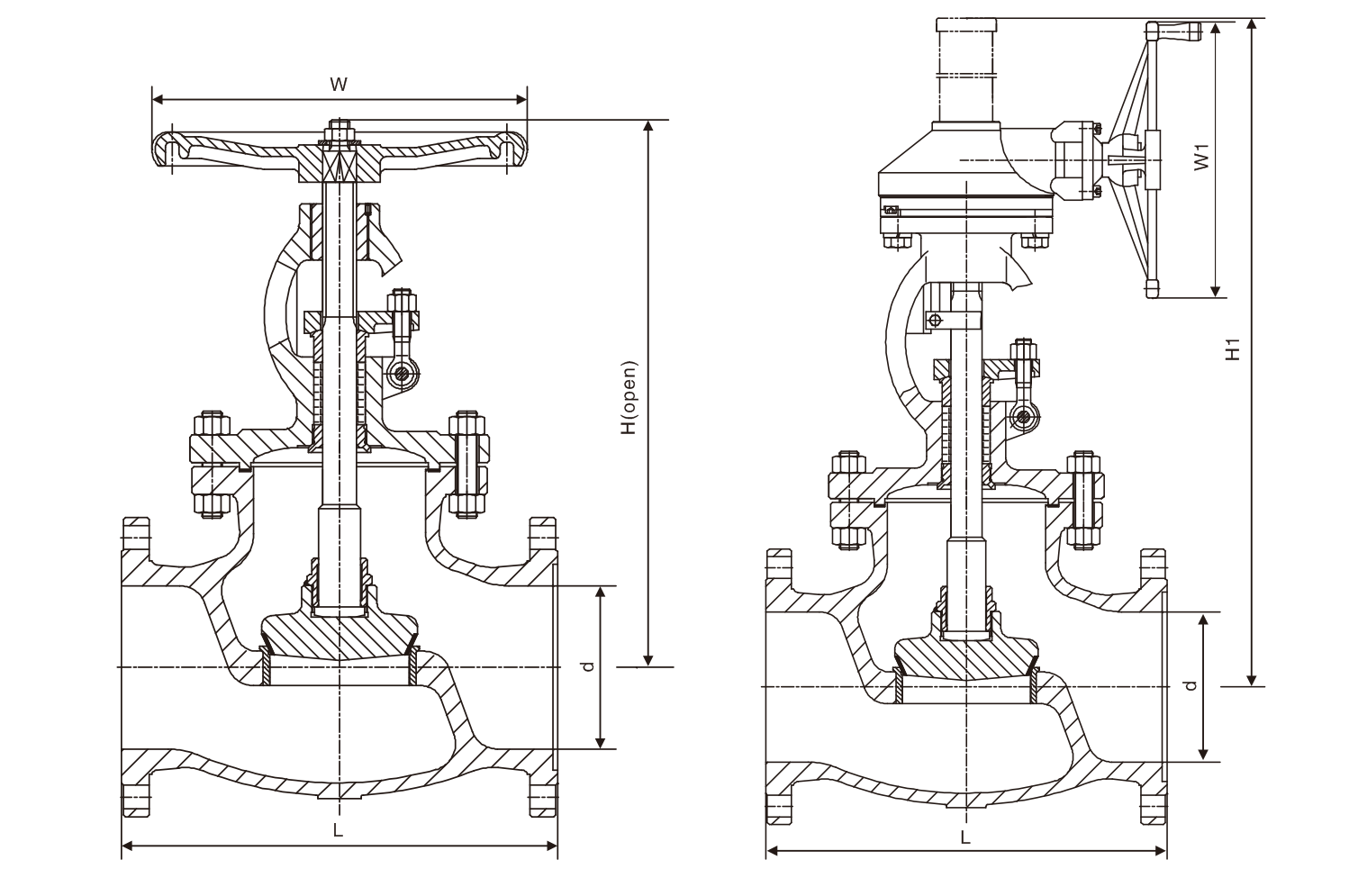

Cryogenic Globe Valve

Nominal diameter: DN15~DN600 (1/2 "~24") Pressure rating: PN16~PN420 (Class150~2500)

Working temperature: -101 ° C, -196 ° C

Connection method: RF, RTJ

Manufacturing standards: national standards, American standards

Operation mode: manual, electric, pneumatic, electric/pneumatic linkage

The ultra-low temperature shut-off valve is suitable for low temperature working conditions of -196 ℃. Adopting advanced design concepts, high-precision processing control, and rigorous process management, strictly controlling various production processes, the SRIT ultra-low temperature valve has outstanding advantages such as reliable sealing, low operating torque, high low-temperature stability, and long service life. The product is widely used in liquefied natural gas, liquefied petroleum gas, air separation, and other low-temperature industries.

Features

1. All

parts of the cryogenic globe valve in contact with the medium are

treated at low temperature to ensure that the valve can be used safely

in a variety of different low-temperature media.

2. According to the

temperature of the medium on site, the valve (minus 46 °C ~ -101 °C)

can be selected with a short shaft globe valve, and the long shaft globe

valve (-101 °C ~ 254 °C) is selected.

Performance Specifications

|

Model |

DJ41Y-16 |

DJ41Y-16P |

DJ41Y-25 |

DJ41Y-25P |

DJ41Y-40 |

DJ41Y-40P |

|

|

Work pressure(MPa) |

1.6 |

2.5 |

4.0 |

||||

|

Proper temperature(℃) |

-45 |

-101 |

-196 |

||||

|

Applicable medium |

LNG, ethylene, propylene and other low temperature media |

||||||

|

Material |

Valve body, bonnet |

LCB |

LC3 |

LCB |

LC3 |

LCB |

LC3 |

|

Disc, seat |

Chromium nickel steel + cobalt chromium tungsten |

||||||

|

Stem |

Chrome Nickel Steel |

||||||

Main external connection dimensions(mm)

| DN | Main external dimensions and connection dimensions | H | ||||||||

| L | D | D1 | D2 | b | Z-d | D0 | -46℃ | -101℃ | -196℃ | |

| DJ41Y-16C DJ41Y-16P DJ41Y-16R DJ641Y-16C DJ641Y-16P DJ641Y-16R DJ9B41Y-16C DJ9B41Y-16P DJ9B41Y-16R | ||||||||||

| 50 | 230 | 160 | 125 | 100 | 16 | 4-18 | 240 | 460 | 480 | 520 |

| 65 | 290 | 180 | 145 | 120 | 18 | 4-18 | 280 | 475 | 505 | 525 |

| 80 | 310 | 195 | 160 | 135 | 20 | 8-18 | 280 | 520 | 550 | 590 |

| 100 | 350 | 215 | 180 | 155 | 20 | 8-18 | 320 | 545 | 575 | 615 |

| 125 | 400 | 245 | 210 | 185 | 22 | 8-18 | 360 | 590 | 620 | 660 |

| 150 | 480 | 280 | 240 | 210 | 24 | 8-23 | 400 | 650 | 650 | 730 |

| 200 | 600 | 335 | 295 | 265 | 26 | 12-23 | 400 | 850 | 850 | 930 |

| 250 | 730 | 405 | 355 | 320 | 30 | 12-25 | 450 | 956 | 986 | 1036 |

| 300 | 850 | 460 | 410 | 375 | 30 | 12-25 | 500 | 1095 | 1125 | 1175 |

| DJ41Y-25 DJ41Y-25P DJ41Y-25R DJ641Y-25C DJ641Y-25P DJ641Y-25R DJ9B41Y-25C DJ9B41Y-25P DJ9B41Y-25R | ||||||||||

| 50 | 230 | 160 | 125 | 100 | 20 | 4-18 | 240 | 460 | 480 | 520 |

| 65 | 290 | 180 | 145 | 120 | 22 | 8-18 | 280 | 475 | 505 | 525 |

| 80 | 310 | 195 | 160 | 135 | 22 | 8-18 | 280 | 520 | 550 | 590 |

| 100 | 350 | 230 | 190 | 160 | 24 | 8-23 | 320 | 545 | 575 | 615 |

| 125 | 400 | 270 | 220 | 188 | 28 | 8-25 | 360 | 590 | 620 | 660 |

| 150 | 480 | 300 | 250 | 218 | 30 | 8-25 | 400 | 650 | 680 | 730 |

| 200 | 600 | 360 | 310 | 278 | 34 | 12-25 | 400 | 850 | 880 | 930 |

| 250 | 730 | 425 | 370 | 332 | 36 | 12-30 | 450 | 956 | 986 | 1036 |

| 300 | 850 | 485 | 430 | 390 | 40 | 16-30 | 500 | 1095 | 1125 | 1175 |

| DJ41Y-40 DJ41Y-40P DJ41Y-40R DJ641Y-40C DJ641Y-40P DJ641Y-40R DJ9B41Y-40C DJ9B41Y-40P DJ9B41Y-40R | ||||||||||

| 50 | 230 | 160 | 125 | 100 | 20 | - | 240 | 483 | 504 | 546 |

| 65 | 290 | 180 | 145 | 120 | 22 | - | 280 | 499 | 530 | 551 |

| 80 | 310 | 195 | 160 | 135 | 22 | - | 280 | 546 | 578 | 620 |

| 100 | 350 | 230 | 190 | 160 | 24 | - | 320 | 572 | 604 | 646 |

| 125 | 400 | 270 | 220 | 188 | 28 | - | 360 | 620 | 61 | 693 |

| 150 | 480 | 300 | 250 | 218 | 30 | - | 400 | 683 | 741 | 767 |

| 200 | 600 | 360 | 320 | 282 | 38 | - | 400 | 893 | 924 | 977 |

| 250 | 730 | 425 | 385 | 345 | 42 | - | 450 | 1004 | 1035 | 1088 |

| 300 | 850 | 485 | 450 | 408 | 46 | - | 500 | 1150 | 1181 | 1234 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333