Non rising stem gate valve

Product model: Z45H/W

Product material: stainless steel

Working temperature: ≤200℃

Applicable medium: water, steam, oil

The non-rising stem gate valve is a gate of the opening and closing part. The direction of movement of the gate is perpendicular to the direction of the fluid. The non-rising stem gate valve can only be fully opened and fully closed, and cannot be adjusted or throttled. The non-rising stem gate valve is sealed by the contact between the valve seat and the gate, and usually the sealing surface will be surfacing with metal materials to increase wear resistance. It is widely used as an opening and closing device for connecting or cutting off the medium in the pipeline of petrochemical industry, thermal power plant and other oil products and steam pipelines.

Main Structure Features Include

1.Non-rising

stem gate valve is featured with compact structure, reasonable design,

high rigidity, smooth fluidity and small fluid resistance coefficient;

2.Sealing surface is made of stainless steel and hard alloy to ensure long service life;

3. Flexible graphite material is used to ensure reliable sealing effect and flexible operation;

4.Drive Type: manual drive, electric drive, gear transmission;

5.Structural Type: elastic wedge single gate, rigid wedge single gate, double gate.

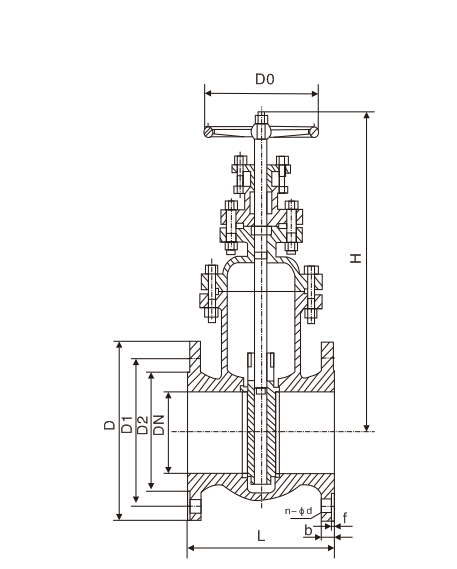

Main external connection dimensions PN 10

|

DN |

L |

D |

D1 |

D2 |

n-d |

H |

D0 |

b-f |

|

50 |

180 |

160 |

125 |

100 |

4-18 |

285 |

180 |

20-3 |

|

65 |

190 |

180 |

145 |

120 |

4-18 |

315 |

180 |

20-3 |

|

80 |

203 |

195 |

160 |

135 |

4-18 |

353 |

200 |

22-3 |

|

100 |

229 |

215 |

180 |

155 |

8-18 |

380 |

200 |

22-3 |

|

125 |

254 |

245 |

210 |

185 |

8-18 |

500 |

240 |

24-3 |

|

150 |

267 |

285 |

240 |

210 |

8-23 |

560 |

240 |

24-3 |

|

200 |

330 |

335 |

295 |

265 |

8-23 |

660 |

320 |

26-3 |

|

250 |

380 |

390 |

350 |

320 |

12-23 |

800 |

320 |

28-3 |

|

300 |

420 |

440 |

400 |

368 |

12-23 |

886 |

400 |

28-4 |

|

350 |

450 |

500 |

460 |

428 |

16-23 |

968 |

400 |

30-4 |

|

400 |

480 |

565 |

515 |

482 |

16-25 |

1090 |

500 |

32-4 |

|

450 |

510 |

615 |

565 |

532 |

20-25 |

1200 |

500 |

32-4 |

|

500 |

540 |

670 |

620 |

585 |

20-25 |

1380 |

600 |

34-4 |

|

600 |

600 |

780 |

725 |

685 |

20-30 |

1500 |

600 |

34-5 |

|

700 |

660 |

895 |

845 |

800 |

24-30 |

2014 |

650 |

40-5 |

|

800 |

720 |

1010 |

950 |

905 |

24-34 |

2368 |

700 |

44-5 |

|

900 |

780 |

1110 |

1050 |

1005 |

28-34 |

2570 |

700 |

46-5 |

|

1000 |

840 |

1220 |

1160 |

1115 |

28-34 |

2740 |

800 |

50-5 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333