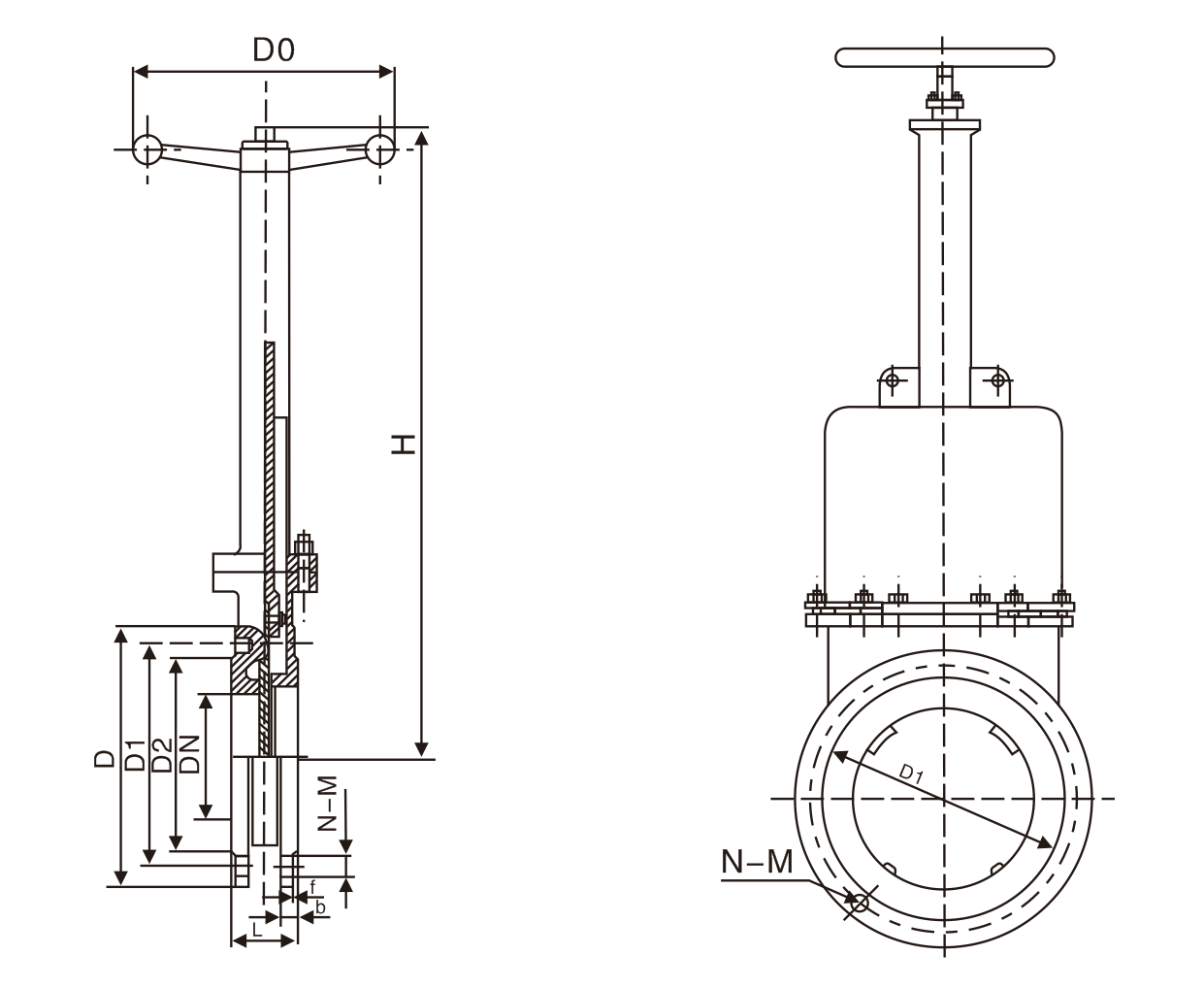

Manual Concealed Plate Knife Gate Valve

Nominal size:2"~36"Nominal pressure: GB PN10, PN16, ASME 150LB, JIS 10K, BS EN, DIN

Diameter range: 2"-50" (DN50-1250mm)

Connection form: wafer type, full lug, round

Transmission mechanism: Manual, Electric, Pneumatic, Hydraulic, Sprocket, Bevel

Gear, Electro-Hydraulic

Main materials: CF3M, CF8M, CF8, CF3

Plate material: SS304, SS316, SS316L

Sealing material: H, W, F, X, (nitrile rubber, EPDM, fluorine rubber)

Packing material: PTFE, Aramid, High Water-Based, Rubber, Graphite

Sealing material: rubber, stainless steel

DMZ73H Manual Concealed Plate Knife Gate Valve has the advantages of short body structure, light weight, the sealing surface of the valve seat can be protected from medium erosion, the sealing surface is evenly pressed, tightly fitted, and dust particles on the sealing surface of the valve seat can be removed during the closing process. It has the advantages of scraping away, tar, etc., convenient sewage discharge, and preventing medium leakage; it is suitable for use in gas pipelines containing dust or tar.

The upper seal of this kind of knife-shaped gate breaks through the conventional sealing form, and adopts the upper cover structure, which makes the upper seal change from a large-area rectangular seal to a small-area circumferential seal, and the sealing performance is greatly improved. On the basis of the circumferential seal, the most advanced floating seal in the world has been changed into an area circumferential seal, and the sealing performance has been greatly improved. On the basis of the circumferential seal, the most advanced floating seal structure in the world is adopted, which makes the upper seal reach the same life as the pipeline, thus improving the service life of the valve as a whole.

Product connection size

|

PN(MPa) |

DN(mm) |

L |

D |

D1 |

D2 |

H |

N-M |

Do |

|

1.0 |

150 |

70 |

280 |

240 |

210 |

475 |

8-M20 |

280 |

|

200 |

80 |

335 |

295 |

265 |

540 |

8-M20 |

360 |

|

|

250 |

85 |

390 |

350 |

320 |

630 |

12-M20 |

360 |

|

|

300 |

100 |

440 |

400 |

368 |

780 |

12-M20 |

400 |

|

|

350 |

100 |

500 |

460 |

428 |

885 |

16-M20 |

400 |

|

|

400 |

110 |

565 |

515 |

482 |

990 |

16-M22 |

400 |

|

|

450 |

120 |

615 |

565 |

532 |

1100 |

20-M22 |

530 |

|

|

500 |

130 |

670 |

620 |

585 |

1200 |

20-M22 |

530 |

|

|

600 |

140 |

780 |

725 |

685 |

1450 |

20-M27 |

600 |

|

|

700 |

165 |

895 |

840 |

800 |

1700 |

24-M27 |

600 |

|

|

800 |

190 |

1010 |

950 |

905 |

2000 |

24-M30 |

680 |

|

|

900 |

200 |

1110 |

1050 |

1005 |

2300 |

28-M30 |

680 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333