Nominal diameter: DN50-DN300 (2 '' -48 '')

Nominal pressure: PN20-PN260 (Class150-2500Lb)

Temperature range: -20 ℃~425 ℃

Valve body material: carbon steel/stainless steel

Valve stem material: SS304

Valve cover material: carbon steel/stainless steel

Valve plate material: SS304

Connection method: wafer type connection

Scope of application: Water, oil, steam, gas, gas, and certain corrosive liquids and other media

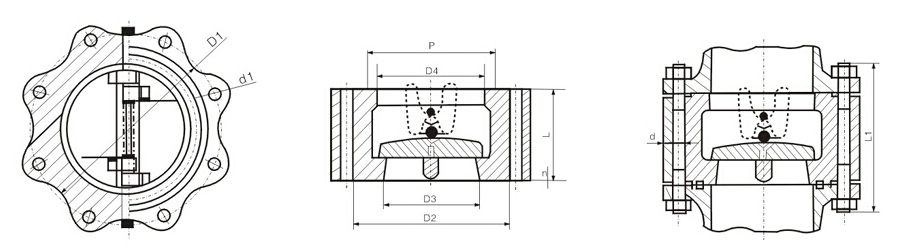

Product Overview

Double disc check valves with clamp lugs are also known as reverse flow valves, check valves, back pressure valves, and one-way valves. This type of valve is an automatic valve that automatically opens and closes by the force generated by the flow of the medium itself in the pipeline. Check valves are used in pipeline systems to prevent media backflow and the discharge of media inside the container. Check valves can also be used to supply pipelines to auxiliary systems where the pressure may rise above the main system pressure.

|

Pressure

rating |

DN

|

Dimension(mm) |

Weight(kg)

|

Flange(as referenced)

|

|||||||||||||||

|

NPS

|

DN

|

L

|

D1

|

D2

|

D3

|

D4

|

P

|

Quantity

of the bolt |

Diameter

of the bolt |

n

|

Quantity

of the bolt |

Diameter of

the bolt |

Length of the bolt

|

||||||

|

RF

|

RJ

|

in

|

mm

|

in

|

mm

|

RF

|

RJ

|

||||||||||||

|

Class 150

PN2.0MPa |

2

|

50

|

60

|

120.5

|

92

|

102

|

51

|

56

|

82.55

|

4

|

3/4

|

19

|

1.6

|

4

|

4

|

5/8

|

M16

|

140

|

155

|

|

2 1/2

|

65

|

67

|

139.5

|

105

|

121

|

65

|

73

|

101.6

|

4

|

3/4

|

19

|

1.6

|

5.5

|

4

|

5/8

|

M16

|

150

|

165

|

|

|

3

|

80

|

73

|

152.5

|

127

|

133

|

80

|

88

|

114.3

|

4

|

3/4

|

19

|

1.6

|

7

|

4

|

5/8

|

M16

|

160

|

175

|

|

|

4

|

100

|

73

|

190.5

|

157

|

171

|

102

|

108

|

149.225

|

8

|

3/4

|

19

|

1.6

|

11

|

8

|

5/8

|

M16

|

170

|

185

|

|

|

5

|

125

|

86

|

216

|

186

|

194

|

127

|

132

|

171.45

|

8

|

7/8

|

22

|

1.6

|

15

|

8

|

3/4

|

M20

|

190

|

205

|

|

|

6

|

150

|

98

|

241.5

|

216

|

219

|

152

|

160

|

193.675

|

8

|

7/8

|

22

|

1.6

|

19

|

8

|

3/4

|

M20

|

205

|

220

|

|

|

8

|

200

|

127

|

298.5

|

270

|

273

|

203

|

210

|

247.65

|

8

|

7/8

|

22

|

1.6

|

36

|

8

|

3/4

|

M20

|

240

|

255

|

|

|

10

|

250

|

146

|

362

|

324

|

330

|

254

|

266

|

304.801

|

12

|

1

|

25

|

1.6

|

61

|

12

|

7/8

|

M24

|

270

|

285

|

|

|

12

|

300

|

181

|

432

|

381

|

406

|

305

|

310

|

381.001

|

12

|

1

|

25

|

1.6

|

119

|

12

|

7/8

|

M24

|

310

|

325

|

|

|

14

|

350

|

184

|

476

|

413

|

425

|

350

|

355

|

396.876

|

12

|

1 1/8

|

29

|

1.6

|

131

|

12

|

1

|

M27

|

325

|

340

|

|

|

16

|

400

|

191

|

540

|

470

|

483

|

400

|

405

|

454.026

|

16

|

1 1/8

|

29

|

1.6

|

180

|

16

|

1

|

M27

|

340

|

355

|

|

|

18

|

450

|

203

|

578

|

533

|

546

|

450

|

455

|

517.526

|

16

|

1 1/4

|

32

|

1.6

|

203

|

16

|

1 1/8

|

M30

|

365

|

380

|

|

|

20

|

500

|

219

|

638

|

584

|

597

|

500

|

505

|

558.801

|

20

|

1 1/4

|

32

|

1.6

|

275

|

20

|

1 1/8

|

M30

|

385

|

400

|

|

|

24

|

600

|

222

|

749.5

|

692

|

711

|

600

|

605

|

673.101

|

20

|

1 1/4

|

35

|

1.6

|

314

|

20

|

1 1/4

|

M33

|

405

|

420

|

|

|

28

|

700

|

305

|

795.5

|

762

|

-

|

700

|

700

|

-

|

40

|

7/8

|

22

|

1.6

|

910

|

40

|

3/4

|

M20

|

455

|

-

|

|

|

30

|

750

|

305

|

846

|

813

|

-

|

746

|

750

|

-

|

44

|

7/8

|

22

|

1.6

|

1025

|

44

|

3/4

|

M20

|

455

|

-

|

|

|

32

|

800

|

305

|

900

|

864

|

-

|

796

|

800

|

-

|

48

|

7/8

|

22

|

1.6

|

1344

|

48

|

3/4

|

M20

|

460

|

-

|

|

|

36

|

900

|

368

|

1009.5

|

972

|

-

|

898

|

910

|

-

|

44

|

1

|

25

|

1.6

|

1536

|

44

|

7/8

|

M24

|

540

|

-

|

|

|

42

|

1050

|

432

|

1171.5

|

1130

|

-

|

1050

|

1055

|

-

|

48

|

1 1/8

|

29

|

1.6

|

2310

|

48

|

1

|

M27

|

625

|

-

|

|

|

48

|

1200

|

524

|

1335

|

1289

|

-

|

1200

|

1205

|

-

|

44

|

1 1/4

|

32

|

1.6

|

3364

|

44

|

1 1/8

|

M30

|

740

|

-

|

|

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333