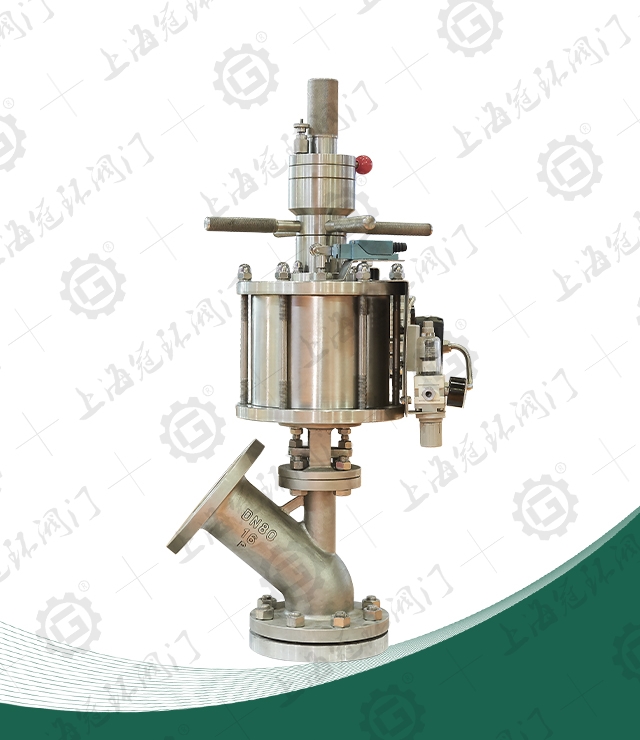

Discharge Ball Valve(Pneumatic)

Nominal Size:DN40~DN200

Pressure Rating:PN6/PN10/PN16;CL150(PN20)

Operateing Temperature:-29℃~316℃

Characteristics:Quickly open

Seat Leakage Class:GB/T 13927-2008: AA、A

Body Material:WCB/WCC/LCB/LCC;WC6/WC9;CF8/CF8M;4A/5A etc.

Trim Material:304+ST/304+RTFE etc.

Seal Material:PTFE, Flexible graphite

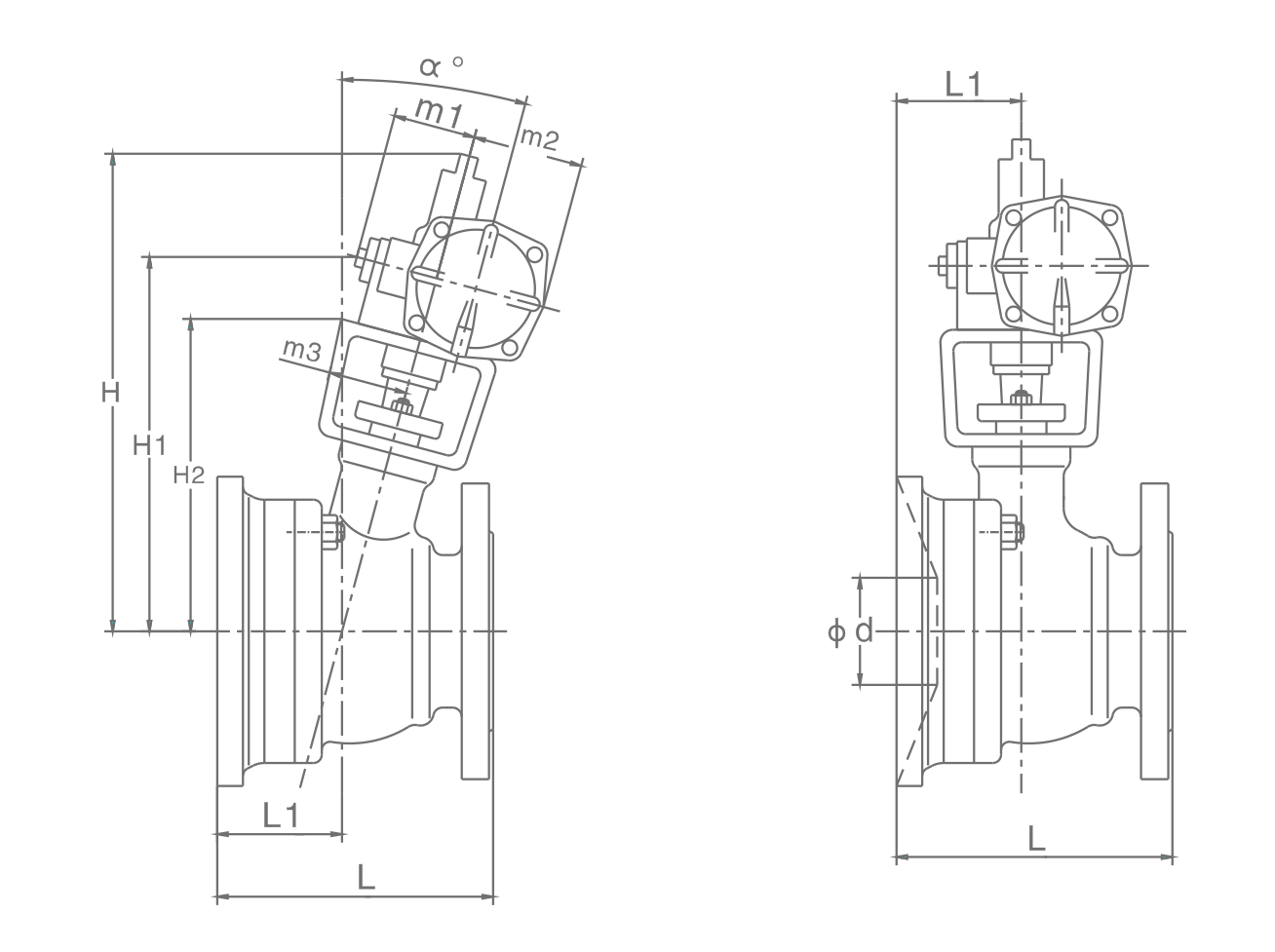

The inclined rod tank bottom ball valve is a full bore straight through ball valve, which can be fully opened or closed by rotating the ball by 90 °. The ball valve is composed of valve body, ball, valve seat, valve stem and other components. The upper neck of the valve body is inclined at a certain angle with the diameter of the chamber, and the installation of the actuator can avoid interference with the reaction kettle. The overall appearance design is beautiful, the valve internal structure is unique, the cutting performance is excellent, and the fluid pressure drop loss is minimal. At the same time, it has functions such as valve stem anti flying, fire prevention and anti-static, suitable for cutting control of various fluids such as liquids and gases.

Product structure characteristics

1. Adopting dewaxing precision casting process;

2. All valves are designed with a full flow chamber, resulting in low fluid pressure drop loss and high flow capacity

3. Adopting a high platform direct installation design and an adjustable invisible packing gland, the pre tightening of the packing can be adjusted without disassembling the cylinder or any other parts. Supports and transmission shafts can be selected according to the working conditions;

4. Fire resistant structure design;

5. Anti static device;

6. Valve stem anti blow out design;

7. Automatic pressure relief design with pressure;

8. The valve stem is installed diagonally and the actuator is rotated 90 ° to avoid interference with the bottom of the pump;

9. The valve seats are all made of imported non-metallic materials, with multiple specifications available, and the maximum temperature can reach 220 ℃;

10. Permissible leakage: meets the requirements of API598, with zero leakage;

11. There are flange types such as RF, RJ, FM, etc. connected to the pipeline.

Main connect dimensions

|

size |

φd |

φD |

H |

L |

L1 |

W |

t0 |

t1 |

m1 |

m2 |

|

20A |

19 |

92 |

217 |

98 |

47 |

211 |

136 |

75 |

45 |

78 |

|

25 |

25 |

125 |

233 |

109 |

54 |

|||||

|

25 |

25 |

125 |

259 |

109 |

54 |

288 |

181 |

105 |

50 |

105 |

|

40 |

38 |

150 |

282 |

126 |

60 |

|||||

|

50 |

51 |

170 |

290 |

139 |

64 |

|||||

|

60 |

51 |

170 |

356 |

139 |

64 |

405 |

257 |

148 |

73 |

155 |

|

65 |

65 |

185 |

391 |

162 |

72 |

|||||

|

80 |

76 |

230 |

410 |

182 |

86 |

|||||

|

100 |

102 |

270 |

435 |

216 |

101 |

|||||

|

80 |

70 |

230 |

473 |

182 |

86 |

574 |

287 |

287 |

71 |

132 |

|

100 |

107 |

270 |

498 |

216 |

101 |

|||||

|

125 |

122 |

310 |

552 |

260 |

120 |

|||||

|

150 |

152 |

360 |

572 |

300 |

140 |

|||||

|

125 |

127 |

310 |

646 |

200 |

120 |

756 |

378 |

378 |

98 |

176 |

|

150 |

152 |

360 |

666 |

300 |

140 |

|||||

|

200 |

203 |

440 |

747 |

381 |

176 |

|||||

|

250 |

254 |

524 |

791 |

449 |

209 |

|||||

|

200 |

203 |

440 |

826 |

381 |

176 |

1060 |

530 |

530 |

118 |

232 |

|

250 |

254 |

524 |

870 |

445 |

209 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333