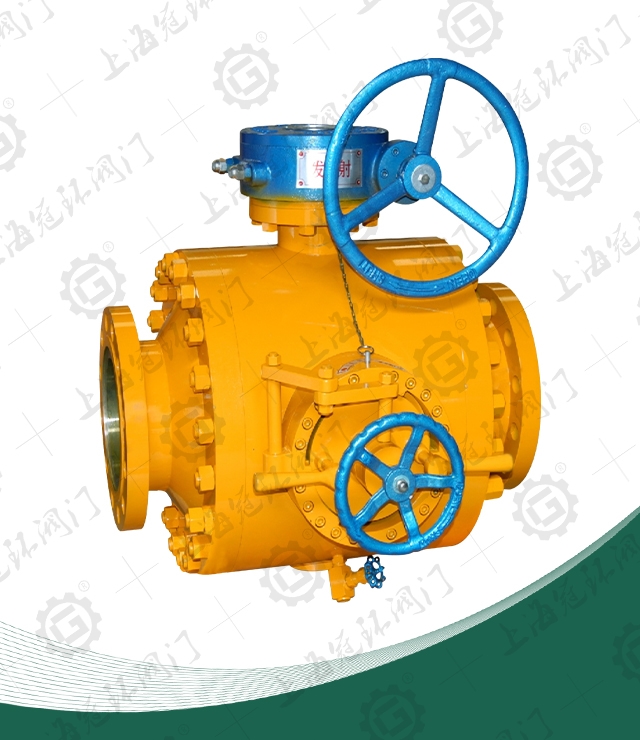

Spherical body fully welded ball valve

Product model: Q367F

Connection: welding, butt welding

Pressure rating: PN 2.5MPa

Product Specification: DN125~600mm

Product material: WCB, A105, F11, F22, F304, F316, C F 8, CF8M, WCC or according to customer requirements

Applicable temperature: -29 ℃ < T < 200 ℃ (different from material of valve body and sealing surface)

Applicable media: water, oil, natural gas, acid-base media, etc.

Drive mode: worm gear drive

Design Specification: API 6D, ASMEB 16.34

Pressure-temperature rating: ASME B16.34, API608

Structure length: ASME B16.10, GB12221

Butt weld end form: ASME B16.25, ASME B31.4/31.8

Inspection and Testing: API 598, API 6D, GB13927

Fire resistance test: API 607, API 6FA

Fully welded ball valves are widely used in various fields.Its superior quality and high performance stability is common cast steel ball valve can not reach, its service life is far greater than cast steel ball valve, all welded ball valve is widely used in city gas, city heating, petrochemical industry, shipbuilding, steel, pressure regulating station, power plant and other kinds of pipe equipment.All-welded ball valves can be buried directly in the ground, do not need to build a tall valve well to reduce the project cost, but also can avoid the damage caused by the operation of the valve, all-welded ball valves can be long-term and reliable operation.Compared with the same specifications in the same industry, the valve body is small and beautiful in appearance.

Structural characteristics

Fully welded ball valves are one-piece, fully welded ball valves with no external leakage. Since the seats are composed of PTFE sealing rings and springs, they are highly adaptable to changes in pressure and temperature and do not cause any leakage in service.The machining process of sphere is tracked and detected by advanced computer tester with high precision.As the valve body material is the same as the pipe material, there will be no uneven stress, no deformation due to earthquake and when the vehicle passes through the ground, and the pipe is aging resistant.The sealing ring body is made of PTFE with 20% C (carbon) content to ensure no leakage (0%).

Main connection dimensions

|

DN(mm) |

Bore |

H |

d |

t |

L |

H1 |

H2 |

I |

ISO |

W T(kg) |

|

A/B |

||||||||||

|

125 |

100 |

193 |

139.7/133 |

5 |

325 |

42 |

221 |

40 |

F07 |

22 |

|

150 |

125 |

219 |

168.3/159 |

6 |

350 |

83 |

245 |

50 |

F10 |

32 |

|

200 |

150 |

273 |

219.1/219 |

7 |

400 |

84 |

289 |

60 |

F12 |

44 |

|

250 |

200 |

351 |

273/273 |

8 |

559 |

90 |

306 |

84 |

F14 |

102 |

|

300 |

250 |

425 |

323.9/325 |

12 |

635 |

87 |

336 |

105 |

F16 |

150 |

|

350 |

300 |

508 |

355.6/377 |

14 |

762 |

102 |

395 |

110 |

F25 |

267 |

|

400 |

350 |

610 |

406.4/426 |

14 |

838 |

95 |

445 |

120 |

F25 |

460 |

|

450 |

400 |

610 |

457/480 |

16 |

914 |

95 |

460 |

120 |

F25 |

550 |

|

500 |

400 |

680 |

508/530 |

18 |

991 |

95 |

522 |

150 |

F30 |

720 |

|

600 |

500 |

813 |

610/630 |

22 |

1143 |

105 |

610 |

170 |

F30 |

1600 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333