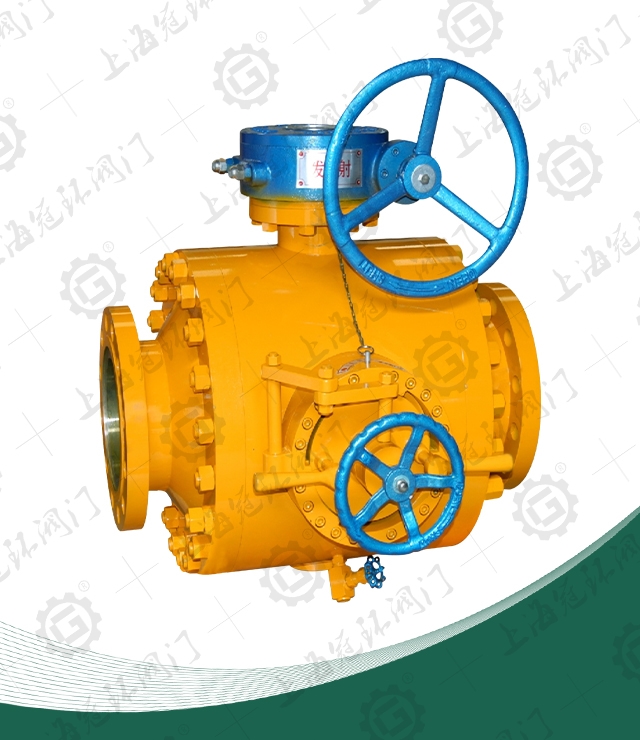

Electric ball type fully welded ball valve

Product model: Q967F

Connection: welding, butt welding

Pressure rating: PN 2.5MPa

Product Specification: DN125~600mm

Product material: WCB, A105, F11, F22, F304, F316, C F 8, CF8M, WCC or according to customer requirements

Applicable temperature: -29 ℃ < T < 200 ℃ (different from material of valve body and sealing surface)

Applicable media: water, oil, natural gas, acid-base media, etc.

Drive mode: worm gear drive

Design Specification: API 6D, ASMEB 16.34

Pressure-temperature rating: ASME B16.34, API608

Structure length: ASME B16.10, GB12221

Butt weld end form: ASME B16.25, ASME B31.4/31.8

Inspection and Testing: API 598, API 6D, GB13927

Fire resistance test: API 607, API 6FA

The electric ball type fully welded ball valve body and cover are made of die forging technology, using a single spherical weld seam. The welding process is fully automatic, with high structural strength, uniform stress, and good bending resistance, and no external leakage points. The integrated design of the ball and valve stem, with special treatment on the surface of the ball, has good corrosion resistance and can adapt to various corrosive media. Widely applicable in large diameter pipelines such as natural gas, petroleum, chemical, and power.

The electric ball type fully welded ball valve is an integrated fully welded ball valve that will not have external leakage or other phenomena. As the valve seat is composed of PTFE sealing rings and springs, it has strong adaptability to pressure and temperature changes and will not produce any leakage within the range of use. The machining process of the sphere is tracked and detected by advanced computer detectors, resulting in high machining accuracy of the sphere. Due to the fact that the valve body material is the same as the pipeline material, there will be no uneven stress, deformation caused by earthquakes and vehicles passing through the ground, and the pipeline is resistant to aging. The sealing ring body is made of PTFE material with a content of 20% C (carbon), ensuring complete leak free (0%).

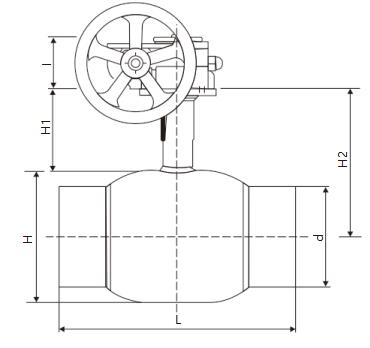

Main connection dimensions

|

DN(mm) |

Bore |

H |

d |

t |

L |

H1 |

H2 |

I |

ISO |

W T(kg) |

|

A/B |

||||||||||

|

125 |

100 |

193 |

139.7/133 |

5 |

325 |

42 |

221 |

40 |

F07 |

22 |

|

150 |

125 |

219 |

168.3/159 |

6 |

350 |

83 |

245 |

50 |

F10 |

32 |

|

200 |

150 |

273 |

219.1/219 |

7 |

400 |

84 |

289 |

60 |

F12 |

44 |

|

250 |

200 |

351 |

273/273 |

8 |

559 |

90 |

306 |

84 |

F14 |

102 |

|

300 |

250 |

425 |

323.9/325 |

12 |

635 |

87 |

336 |

105 |

F16 |

150 |

|

350 |

300 |

508 |

355.6/377 |

14 |

762 |

102 |

395 |

110 |

F25 |

267 |

|

400 |

350 |

610 |

406.4/426 |

14 |

838 |

95 |

445 |

120 |

F25 |

460 |

|

450 |

400 |

610 |

457/480 |

16 |

914 |

95 |

460 |

120 |

F25 |

550 |

|

500 |

400 |

680 |

508/530 |

18 |

991 |

95 |

522 |

150 |

F30 |

720 |

|

600 |

500 |

813 |

610/630 |

22 |

1143 |

105 |

610 |

170 |

F30 |

1600 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333