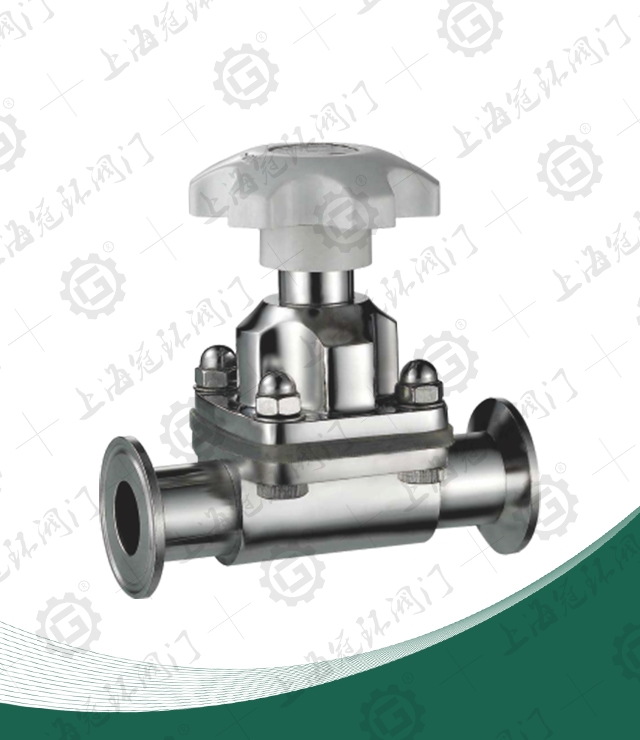

Sanitary threaded check valve

Nominal pressure: PN0.6~1.0MPa

Applicable temperature: ≤ 85 ℃

Applicable media: beer, dairy, beverages, pharmaceuticals, etc

Main materials: SUS304, SUS316L stainless steel, etc

A threaded check valve refers to a type of valve with a circular disc as the opening and closing part, which acts by its own weight and medium pressure to block medium backflow. It belongs to the category of automatic valves, also known as check valves, one-way valves, return valves, or isolation valves. The movement mode of the valve disc is divided into lifting type and swing type. The lifting check valve is similar in structure to a globe valve, except for the lack of a stem that drives the valve disc. The medium flows in from the inlet end (lower side) and out from the outlet end (upper side). When the inlet pressure is greater than the sum of the weight of the valve disc and its flow resistance, the valve is opened. On the contrary, when the medium flows back, the valve closes. The swing check valve has a valve disc that is tilted and can rotate around the axis, and its working principle is similar to that of a lift check valve. A check valve is commonly used as the bottom valve of a pumping device to prevent water from flowing back. The combination of check valves and globe valves can provide safety isolation. The disadvantage is high resistance and poor sealing when closing.

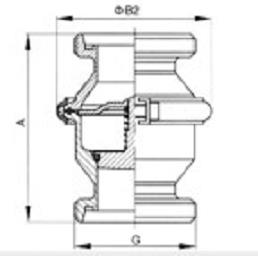

Main overall connection dimensions

|

Threaded check valve/DIN |

|||

|

Size |

B2 |

G |

A |

|

DN15 |

87.0 |

RD34×1/8 |

110.5 |

|

DN20 |

87.0 |

RD44×1/8 |

114.5 |

|

DN25 |

87.0 |

RD52×1/8 |

116.5 |

|

DN32 |

87.0 |

RD58×1/8 |

116.5 |

|

DN40 |

87.0 |

RD65×1/8 |

116.5 |

|

DN50 |

100.0 |

RD78×1/8 |

130.0 |

|

DN65 |

115.0 |

RD95×1/8 |

142.5 |

|

DN80 |

128.0 |

RD110×1/8 |

166.5 |

|

DN100 |

154.0 |

RD130×1/8 |

212.5 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333