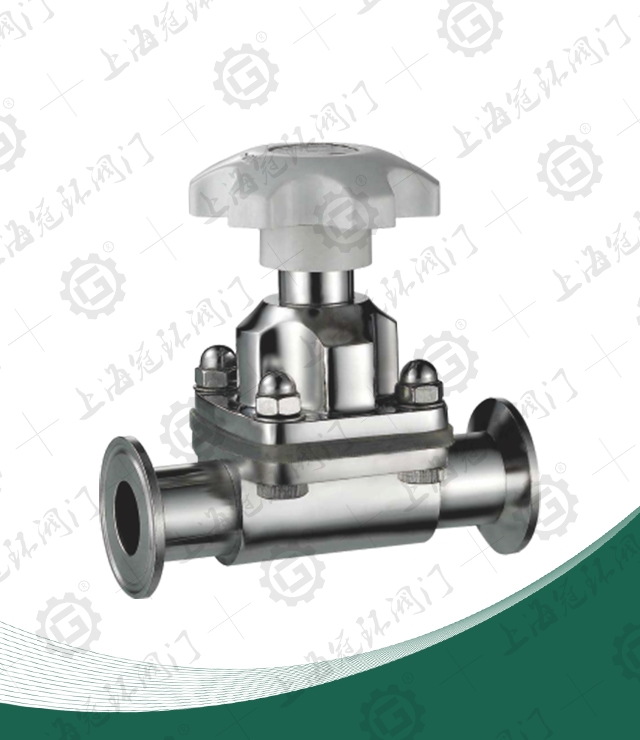

Sanitary welded check valve

Nominal pressure: PN0.6~1.0MPa

Applicable temperature: ≤ 85 ℃

Applicable media: beer, dairy, beverages, pharmaceuticals, etc

Main materials: SUS304, SUS316L stainless steel, etc

The function of sanitary grade

welded check valves is to only allow medium to flow in one direction and

prevent flow in the opposite direction. Usually, this type of valve

operates automatically, and under the pressure of fluid flowing in one

direction, the valve disc opens; When the fluid flows in the opposite

direction, the valve seat is cut off by the fluid pressure and the self

closing of the valve disc, which acts on the valve seat.

working principle

When the pressure below the valve stem exceeds the pressure above the

valve stem and the spring force, the check valve opens. When the

pressure on the valve stem is balanced, the valve will close. A higher

reverse pressure will act on the valve stem to close it. Used in

stainless steel pipeline systems to prevent fluid backflow.

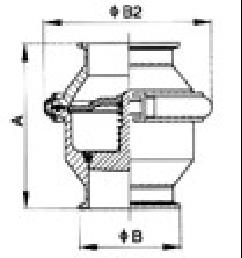

Main overall connection dimensions

|

Clamp type check valve/3A |

|||

|

Size |

B2 |

D |

A |

|

1/2" |

87.0 |

25.4 |

102.0 |

|

3/4" |

87.0 |

25.4 |

102.0 |

|

1" |

87.0 |

50.5 |

102.0 |

|

1 1/2" |

87.0 |

50.5 |

102.0 |

|

2" |

100.0 |

54 |

113.4 |

|

2 1/2" |

115.0 |

77.5 |

122.0 |

|

3" |

128.0 |

91.0 |

142.0 |

|

4" |

164.0 |

119.0 |

182.0 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333