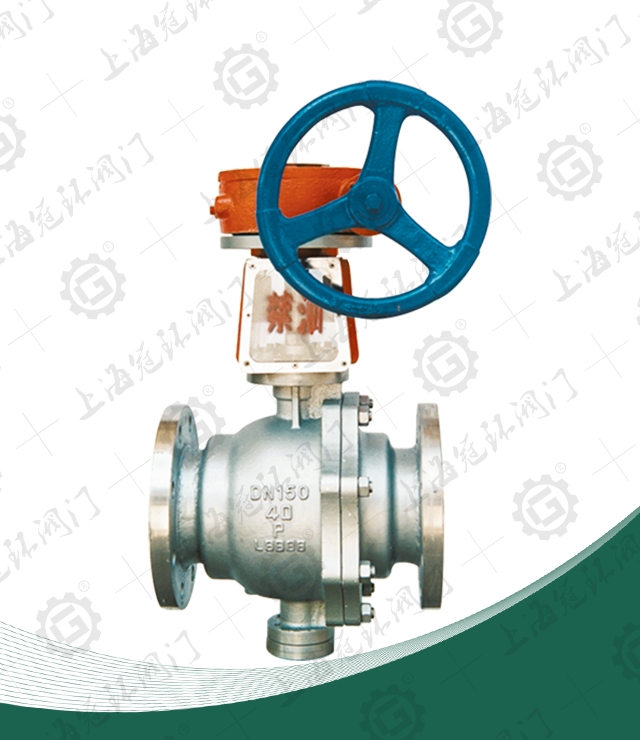

All copper oxygen lift check valve

Product overview

Performance characteristics

1, the valve is generally suitable for clean media, not suitable for media containing solid particles and large viscosity.

2,

the valve bushing is made of special materials with good wear

resistance and small friction coefficient, flexible and reliable action,

and excellent sealing performance.

3.

The valve has novel structure, small size, light weight, small fluid

resistance, stable opening and closing, long service life, oil pressure

and slow closing are not affected by the medium, and has good

energy-saving effect.

4,

the valve can be installed at the pump outlet, can avoid the production

of water hammer, water percussion sound and destructive impact, to

prevent countercurrent and protect the purpose of equipment.

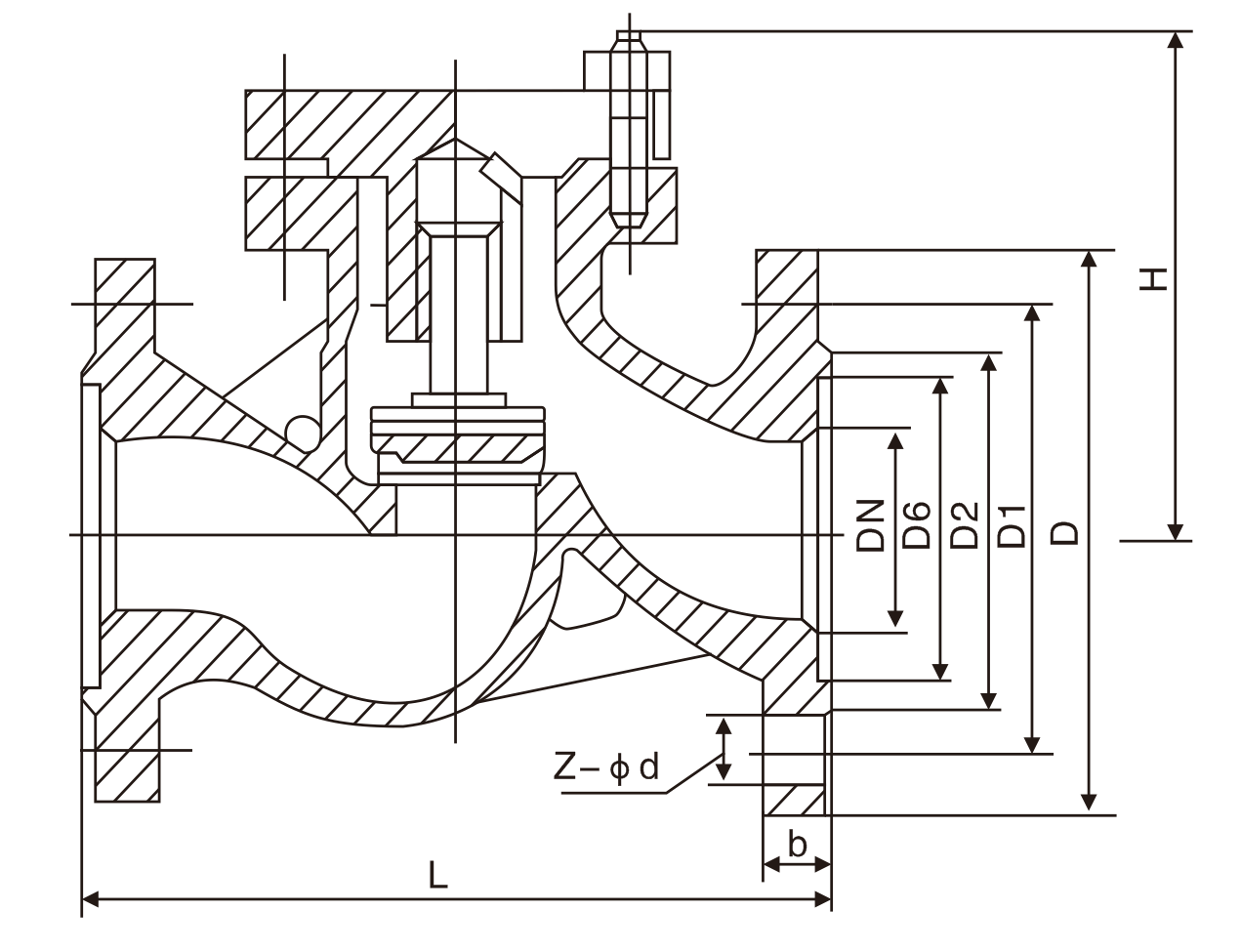

Main contour connection dimensions

|

Model |

|

size㎜ |

||||||

|

L |

D |

D1 |

D2 |

Z-фd |

b |

H |

||

|

HY41W-16T |

15 |

130 |

95 |

65 |

45 |

4-ф14 |

14 |

77 |

|

20 |

150 |

105 |

75 |

55 |

4-ф14 |

14 |

77 |

|

|

25 |

160 |

115 |

85 |

65 |

4-ф14 |

16 |

80 |

|

|

32 |

180 |

135 |

100 |

78 |

4-ф18 |

16 |

85 |

|

|

40 |

200 |

145 |

110 |

85 |

4-ф18 |

16 |

95 |

|

|

50 |

230 |

160 |

125 |

100 |

4-ф18 |

16 |

105 |

|

|

65 |

290 |

180 |

145 |

120 |

4-ф18 |

18 |

120 |

|

|

80 |

310 |

195 |

160 |

135 |

8-ф18 |

20 |

130 |

|

|

100 |

350 |

215 |

180 |

155 |

8-ф18 |

20 |

140 |

|

|

125 |

400 |

245 |

210 |

185 |

8-ф18 |

22 |

155 |

|

|

150 |

480 |

280 |

240 |

210 |

8-ф23 |

24 |

180 |

|

|

200 |

600 |

335 |

295 |

265 |

12-ф23 |

26 |

215 |

|

|

HY41W-25T |

15 |

130 |

95 |

65 |

45 |

4-ф14 |

16 |

77 |

|

20 |

150 |

105 |

75 |

55 |

4-ф14 |

16 |

77 |

|

|

25 |

160 |

115 |

85 |

65 |

4-ф14 |

16 |

80 |

|

|

32 |

180 |

135 |

100 |

78 |

4-ф18 |

18 |

85 |

|

|

40 |

200 |

145 |

110 |

85 |

4-ф18 |

18 |

95 |

|

|

50 |

230 |

160 |

125 |

100 |

4-ф18 |

20 |

105 |

|

|

65 |

290 |

180 |

145 |

120 |

8-ф18 |

22 |

120 |

|

|

80 |

310 |

195 |

160 |

135 |

8-ф18 |

22 |

130 |

|

|

100 |

350 |

230 |

190 |

160 |

8-ф23 |

24 |

140 |

|

|

125 |

400 |

270 |

220 |

188 |

8-ф25 |

28 |

155 |

|

|

150 |

480 |

300 |

250 |

218 |

8-ф25 |

30 |

180 |

|

|

200 |

600 |

360 |

310 |

278 |

12-ф30 |

34 |

215 |

|

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333