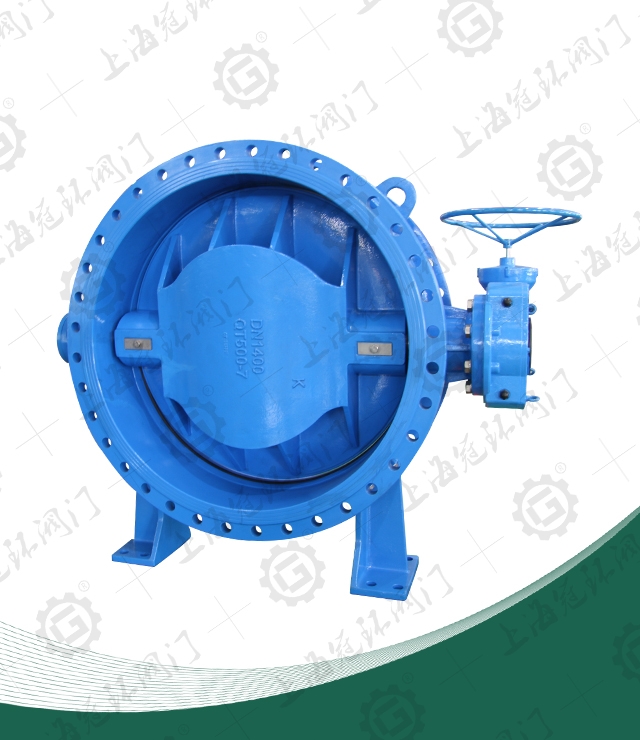

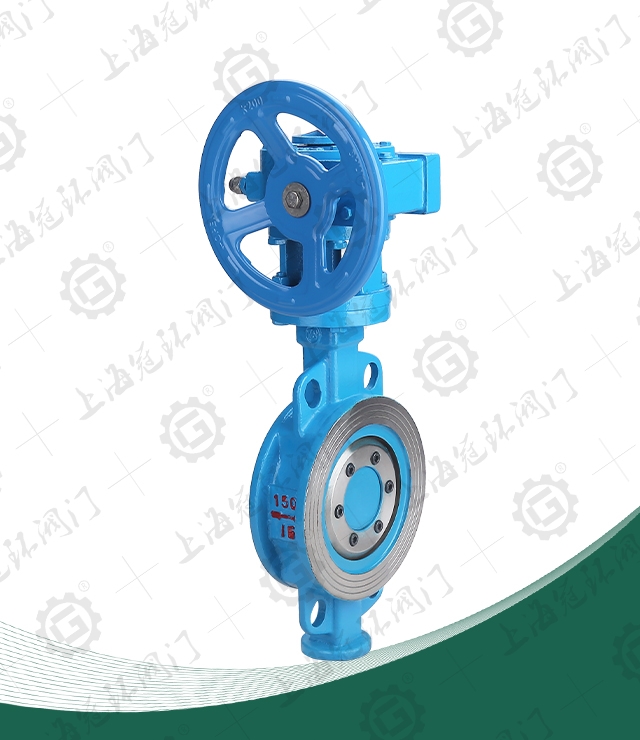

Hydraulic control check butterfly valve

Nominal diameter: DN1200~3500mm

Nominal pressure: PN0.25~1.0MPa

Applicable temperature: ≤80°C

Applicable medium: water, seawater, sediment water, oil and other non-corrosive fluids

The heavy hammer type hydraulic control check butterfly valve is mainly installed in the inlet of the hydropower station turbine and is used as the inlet valve of the hydropower station; Or installed in the outlet of the pump in various pumping stations such as water conservancy, electric power, water supply and drainage, replacing the role of check valve and gate valve. When working, the valve cooperates with the pipeline host, according to the principle of hydraulic transition process, through the preset opening and closing procedure, to achieve reliable cut-off of the pipeline, effectively eliminate the water hammer of the pipeline, and play a role in protecting the safety of the pipeline system. The valve is suitable for water, seawater, oil and other non-corrosive fluid media, and can be used for start-stop and shut-off functions in the outlet or line of the pump.

Structural features

1.

It can replace the outlet globe valve and check valve of the water

pump, and integrate machine, electricity and hydraulic, and occupy a

small area.

2. High degree of automation, can be local, remote and linkage control.

3. The electrical system can adopt PLC intelligent control system or ordinary relay system.

4. The hydraulic system motor has low power, high work efficiency, good

pressure holding performance, and long oil pump start interval.

5. The hydraulic system has automatic pressure holding function, long

pressure holding time, and the oil pump starting interval can reach 500

hours.

6.

There are obvious opening indication and mechanical limit adjustment

mechanism, stroke switch device waterproof and dustproof design, not

exposed, stable performance, long service life.

7. The electrical operation interface is humanized and diversified, and

ordinary buttons, text and touch screen can be designed, and the

man-machine operation interface can be designed according to the needs

of customers.

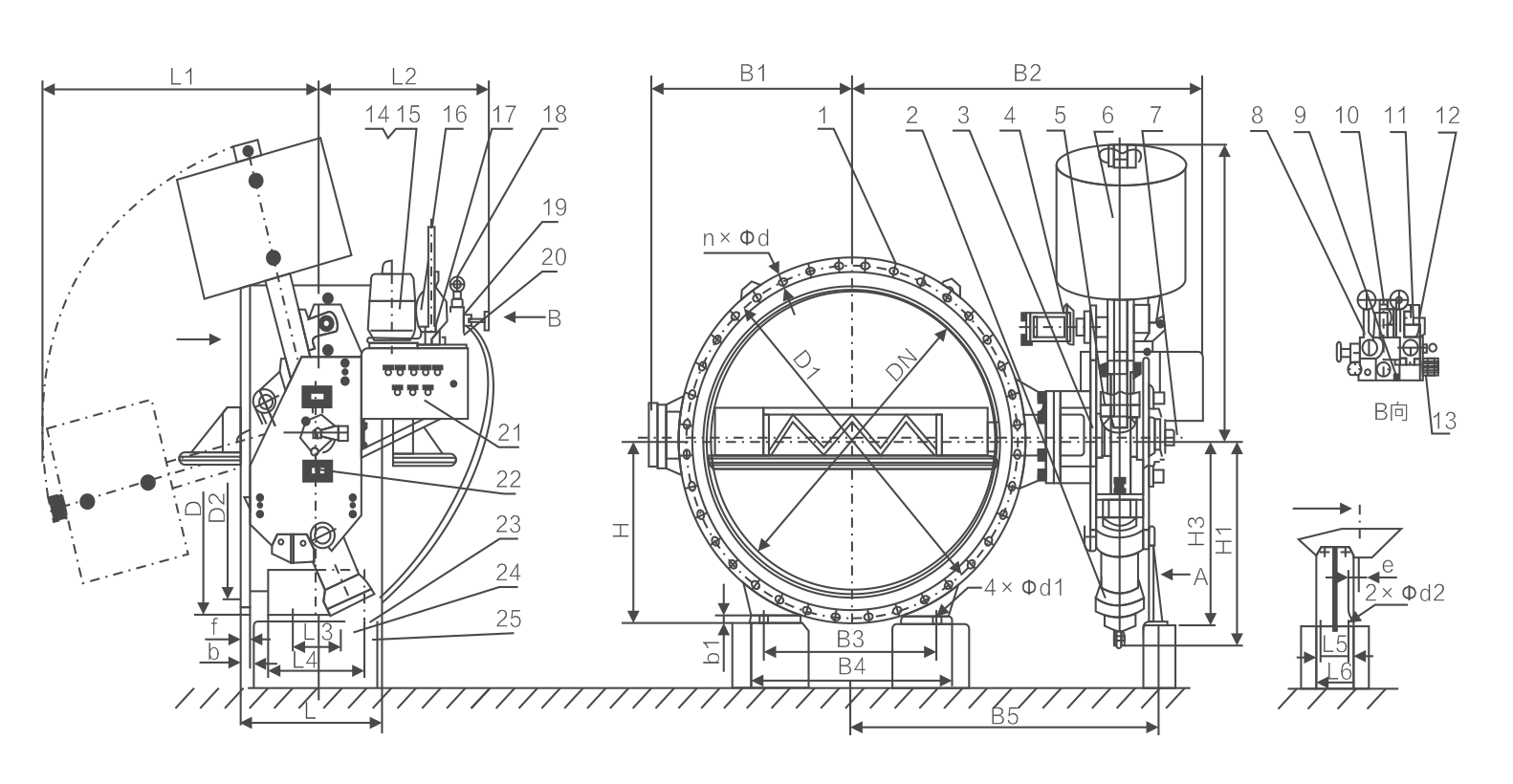

Main appearance and connection dimensions(PN0.6MPa)

|

DN(mm) |

L |

D |

D1 |

D2 |

b |

f |

n |

d |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

H |

H1 |

H2 |

H3 |

|

1200 |

630 |

1405 |

1340 |

1295 |

28 |

5 |

32 |

34 |

1450 |

860 |

200 |

360 |

160 |

220 |

810 |

935 |

1350 |

685 |

|

1300 |

710 |

1520 |

1450 |

1405 |

32 |

5 |

32 |

37 |

1510 |

870 |

260 |

400 |

160 |

220 |

860 |

1065 |

1475 |

820 |

|

1400 |

710 |

1630 |

1560 |

1510 |

32 |

5 |

36 |

37 |

1765 |

870 |

260 |

400 |

160 |

220 |

940 |

1065 |

1475 |

820 |

|

1500 |

790 |

1730 |

1660 |

1610 |

34 |

5 |

36 |

37 |

1765 |

870 |

260 |

400 |

160 |

220 |

1000 |

1065 |

1475 |

820 |

|

1600 |

790 |

1830 |

1760 |

1710 |

34 |

5 |

40 |

37 |

1765 |

870 |

270 |

400 |

160 |

220 |

1080 |

1075 |

1720 |

820 |

|

1750 |

870 |

1995 |

1920 |

1868 |

36 |

5 |

44 |

40 |

1960 |

870 |

270 |

500 |

160 |

220 |

1130 |

1075 |

1720 |

820 |

|

1800 |

870 |

2045 |

1970 |

1918 |

36 |

5 |

44 |

40 |

1960 |

870 |

270 |

500 |

160 |

220 |

1130 |

1075 |

1720 |

820 |

|

2000 |

950 |

2265 |

2180 |

2125 |

38 |

5 |

48 |

43 |

2060 |

910 |

360 |

560 |

200 |

280 |

1250 |

1180 |

1990 |

910 |

|

2200 |

1000 |

2475 |

2390 |

2335 |

42 |

6 |

52 |

48 |

2060 |

910 |

360 |

600 |

200 |

280 |

1320 |

1180 |

1990 |

910 |

|

2400 |

1000 |

2685 |

2600 |

2545 |

44 |

6 |

56 |

48 |

2150 |

910 |

400 |

600 |

200 |

280 |

1440 |

1250 |

2080 |

980 |

|

2600 |

1000 |

2905 |

2810 |

2750 |

46 |

6 |

60 |

49 |

2150 |

910 |

500 |

700 |

200 |

280 |

1520 |

1250 |

2080 |

980 |

|

2800 |

1000 |

3115 |

3020 |

2960 |

48 |

6 |

64 |

49 |

2050 |

910 |

600 |

750 |

200 |

280 |

1620 |

1180 |

1990 |

1050 |

|

3000 |

1000 |

3315 |

3220 |

3160 |

50 |

6 |

68 |

49 |

2050 |

950 |

600 |

800 |

200 |

280 |

1720 |

1180 |

1990 |

1050 |

|

3200 |

1200 |

3525 |

3430 |

3370 |

54 |

6 |

72 |

49 |

2150 |

950 |

700 |

900 |

200 |

280 |

1820 |

1250 |

2080 |

1180 |

|

3400 |

1200 |

3735 |

3640 |

3580 |

56 |

6 |

76 |

49 |

2150 |

950 |

750 |

1000 |

200 |

280 |

1920 |

1250 |

2080 |

1180 |

|

3500 |

1200 |

3920 |

3780 |

3685 |

70 |

6 |

78 |

49 |

2150 |

950 |

750 |

1000 |

200 |

280 |

1980 |

1250 |

2080 |

1180 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333