Aluminum alloy pipe clamp valve

Product model: GJ41X

Nominal diameter: DN25-300

Nominal pressure: PN0.6-1.6MPa

Applicable media: pulp, sewage, slag, coal slag, sediment, etc

Applicable temperature: -30-85 ℃

Main material: aluminum alloy

Flange execution standard: JB/80-91

Product Overview

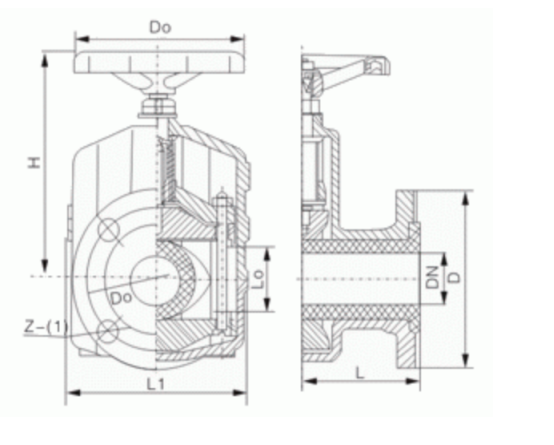

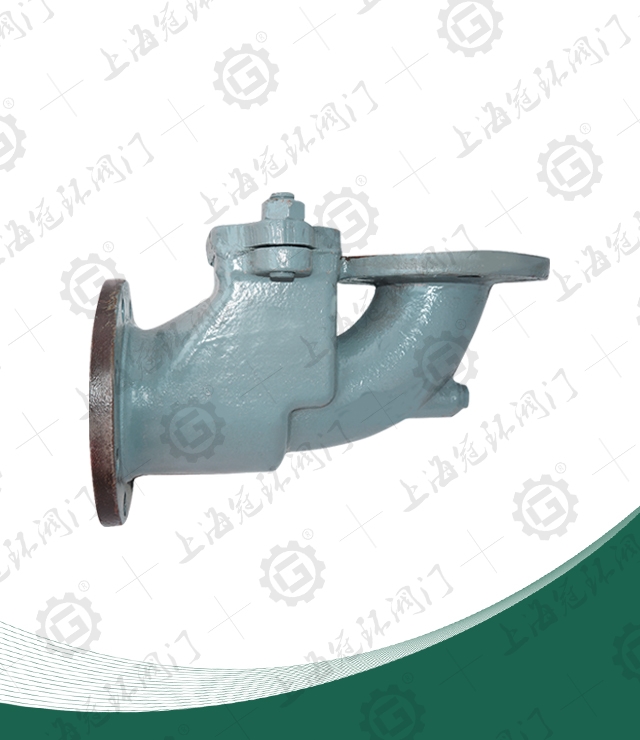

Aluminum alloy pipe clamp valve, also known as aluminum alloy pipe clamp valve, aluminum alloy rubber pipe valve, consists of left and right aluminum alloy valve bodies, rubber pipe sleeves, large and small valve stems, upper and lower gate plates, pull rods, brackets, handwheels, and other parts. Wear resistance, anti-corrosion, frost resistance, and good sealing performance. Simply replace the rubber sleeve and it will be as good as new. The valve body can be permanently used, with a lifespan of 4-6 times that of ordinary valves. There are various driving methods such as manual, pneumatic, and electric, and non-standard products can also be customized according to customer needs.

operational principle

When turning the handwheel clockwise, the large and small valve stems simultaneously drive the upper and lower pressure plates to compress the pipe sleeve for closure. Reverse to open, so that the pressure plate moves up and down between the pull rods to complete the valve opening and closing work.

Main contour connection dimensions

|

Nominal diameter (DN) |

Nominal pressure (MPa) |

Work stress (MPa) |

L |

L1 |

D |

D1 |

Z-Φ |

|

25 |

0.6 |

0.6 |

160 |

124 |

115 |

85 |

4-14 |

|

32 |

165 |

145 |

140 |

100 |

4-18 |

||

|

40 |

190 |

157 |

150 |

110 |

4-18 |

||

|

50 |

210 |

160 |

160 |

125 |

4-18 |

||

|

65 |

250 |

199 |

180 |

145 |

4-18 |

||

|

80 |

300 |

222 |

195 |

160 |

4-18 |

||

|

100 |

350 |

250 |

215 |

180 |

8-18 |

||

|

125 |

430 |

318 |

245 |

210 |

8-18 |

||

|

150 |

500 |

350 |

280 |

240 |

8-23 |

||

|

200 |

0.4 |

0.4 |

650 |

446 |

335 |

295 |

8-23 |

|

250 |

800 |

516 |

395 |

350 |

12-23 |

||

|

300 |

950 |

562 |

445 |

400 |

12-23 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333